Introduction

Dear TI Team

We are currently struggling with a new PCBA where we use a TPS62133 to convert 12VDC to 5VDC. On a first validation batch of 60 boards, about 15% of these boards the TPS62133 (U301) failed after 1-10 days of operation.

To start the discussion I’ll try to provide a more detailed description of the problem below.

As we run out of ideas where the problem could come from or how to solve it, we would highly appreciate any input or ideas.

Best regards

Diego

Failure Description

- Out of 60 boards 8 boards (ICs) failed

- The failure happened

- on 6 instances in the first 1-4 days of operation, on the other 2 instances after about 10 days of operation.

- When the system was in “standby” – in this state the converter is loaded with about 1A by an “embedded linux module with an LCD display”

- The failure was

- On 7 of the 8 failed boards, the 5V output was not there anymore. On 1 instance the 5V was output was gone and additionally the 12V input was shortened.

- Replacing the TPS62133 solved the problem on all of the failed boards

- Additional comments

- On the board there are 2 instances of the TPS62133-based DC/DC converters: U300 and U301 (see schematic). U300 never failed so far, but it is also loaded a little less (about 0.5 A) and the layout is minimally different.

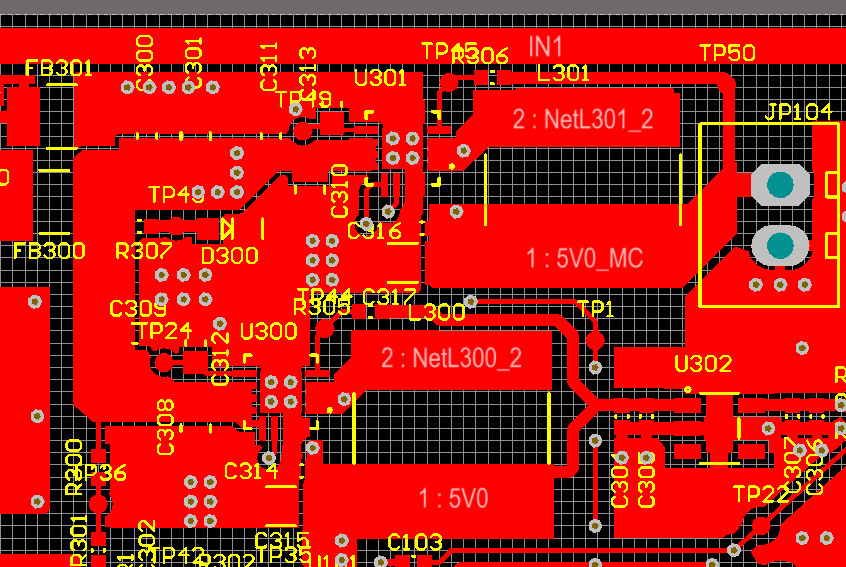

Current schematic and layout

- Note: U301 failed sporadically (U300 is just shown for sake of completeness, e.g. with respect to thermal considerations or similar)

Top layer and top overlay

Bottom layer and top overlay

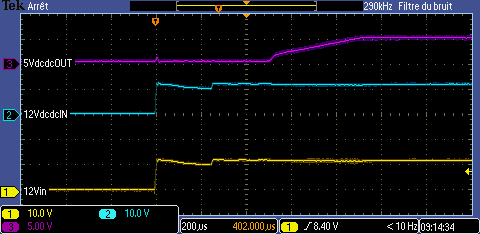

Measurements of input-/output-voltages

- Switching 12V input “on”:

- 5VdcdcOUT corresponds to 5V0_MC

- 5V0_MC is loaded with about 1A by a LCD/backlight module.

- System in “standby”:

- 5VdcdcOUT corresponds to 5V0_MC

- 5V0_MC is loaded with about 1A by a LCD/backlight module.

- System during “normal usage cycle” ”:

- 5VdcdcOUT corresponds to 5V0_MC

- 5V0_MC is loaded with about 1A by a LCD/backlight module.

- Note: The “spikes” on the 12V input are due to load transients (~2A) on the second TPS62133 regulator generating the “5V0”.

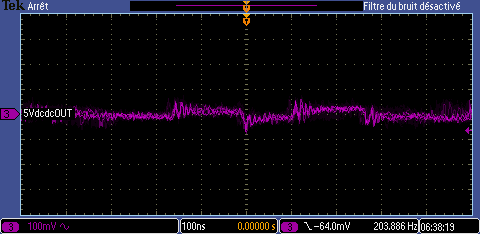

- System in “standby” – measured on a modified pcba:

- For this measurement a second 22uF capacitor was soldered on parallel to C317.

- 5VdcdcOUT corresponds to 5V0_MC

- 5V0_MC is loaded with about 1A by a LCD/backlight module.

Temperature Measurements

- Measurement setup:

- The measurements were done using thermocouple (elements/sensors) and a UT71E multimeter.

- The thermocouple was placed either “on the top of the case of U301” or “on the bottom side of the pcb at the center of the thermal pad of U301” in both cases using “thermal heatsink paste” to get an acceptable thermal contact.

- The system was left powered for a few minutes till the temperature was stable.

- For these measurements the output 5V0_MC was loaded (by resistors) with 1A, 1.5A and 2A.

- Measured temperatures (after about 5 minutes of operation):

- At 1A (resistive) load

- Top of case of U301: 44°C

- Bottom side (vis-à-vis thermal pad): 43°C

- Estimated/calculated chip temperature : 52°C

- At 1.5A (resistive) load

- Top of case of U301: 59°C

- Bottom side (vis-à-vis thermal pad): 53°C

- Estimated/calculated chip temperature : 70°C

- At 2A (resistive) load

- Top of case of U301: 80°C

- Bottom side (vis-à-vis thermal pad): 70°C

- Estimated/calculated chip temperature : 95°C

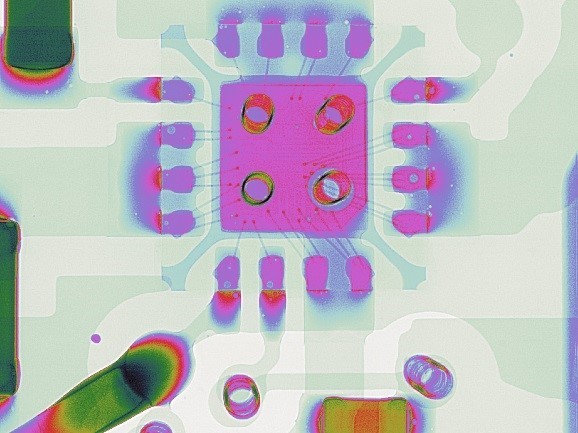

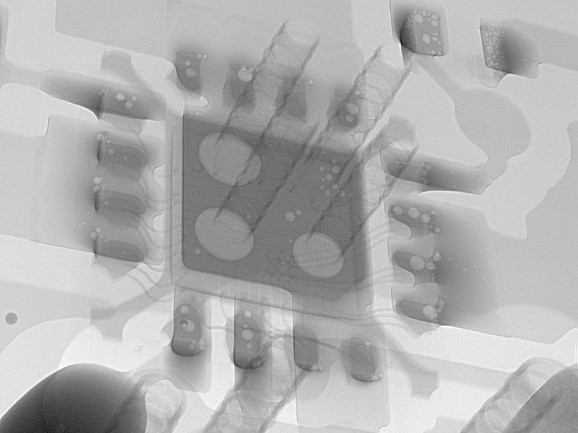

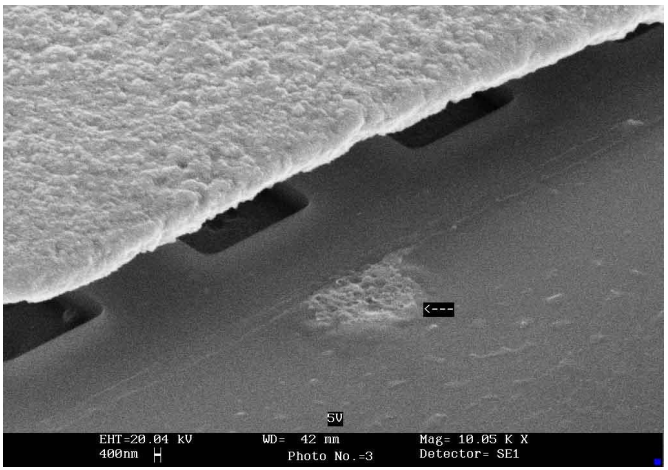

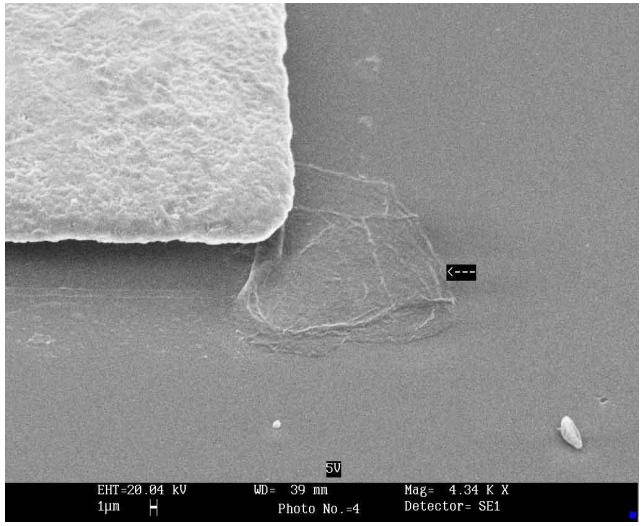

X-Ray analysis

- Initial comments

- So far only 1 boards/U301 were x-rayed.

- 1 of these boards had “failed” before x-raying

- 1 of these boards had worked for several weeks (without failure) before x-raying.

- It seems that there was no significant difference and the wetting/soldering of the thermal pad seems ok.

- X-rays of approximately 30 more boards will be added soon.

- X-rays of a “failed” board

- X-rays of a “good/working” board

Theories and Thoughts

- Over-/Undervoltage problem

- Seems to not be the cause because

- no voltage measurement showed spikes/peaks exceeding maximum values.

- Anyway it may be a problem because

- A “failure” could never be observed “directly”. The measurements were done on a “working” board, which may show a different behavior than a board that would fail after a few days.

- Thermal problem / Overload

- Seems to not be the cause because

- The thermal measurements showed, that the temperature should be acceptable at the given load (1A) and even at higher loads (1.5A)

- No failure could be “produced/reproduced” when intentionally “heavily using the system” (which results in maximum realistic load)

- No failure could be produced when powering the board at 70°C environment temperature, even at higher loads (1.5A) then in the system.

- No failure could be produced, when shorting the 5V0_MC during 5 minutes (which results in a 4A load current)

- Anyway it may be a problem because

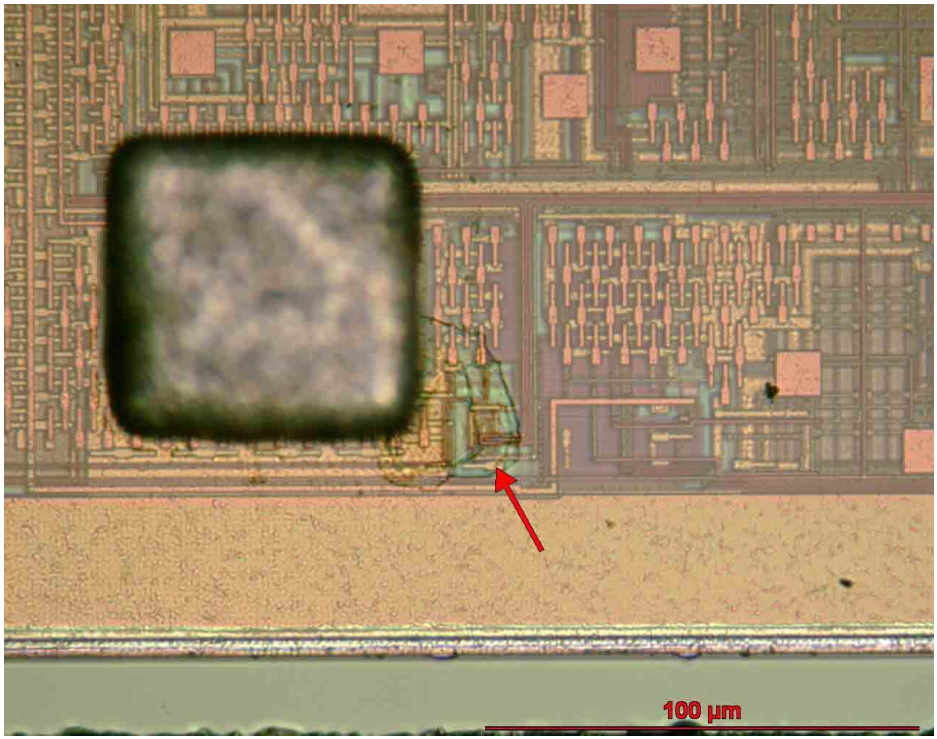

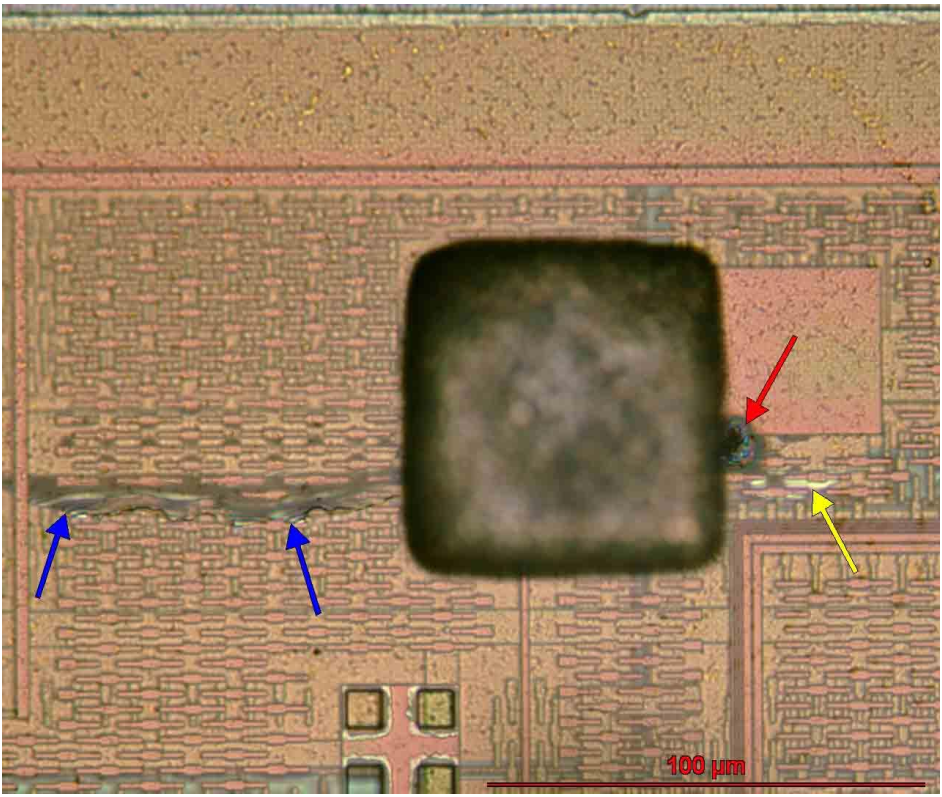

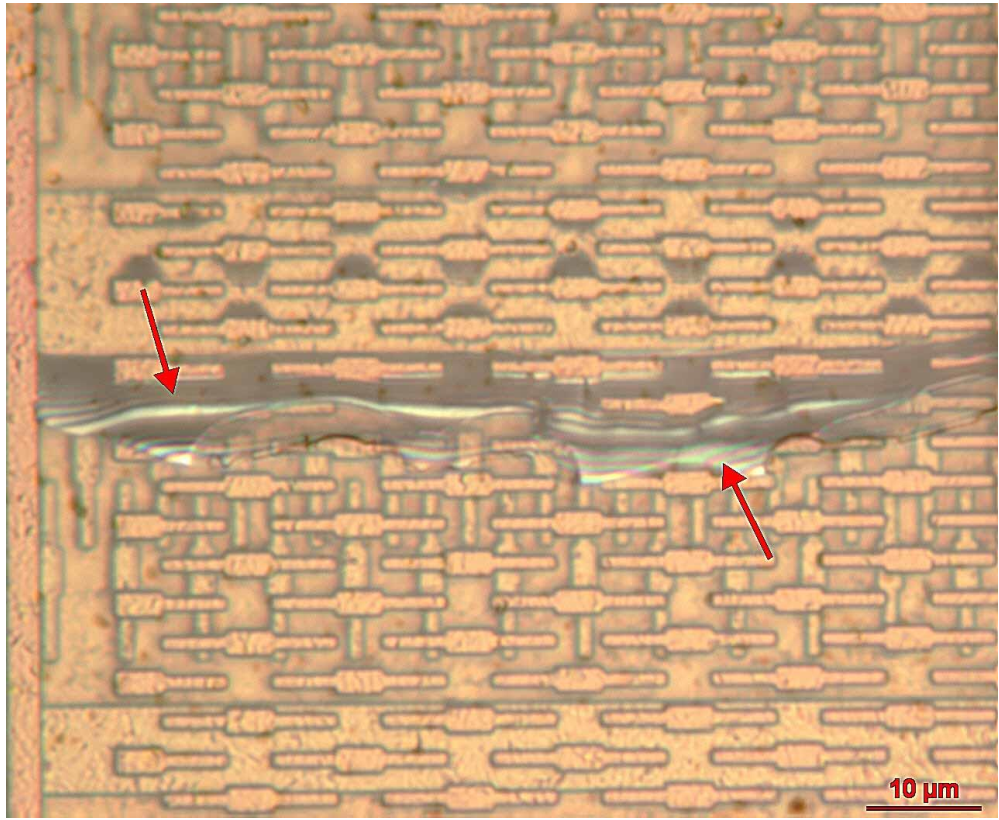

- Only 4 vias are used.

- These 4 vias are “plugged” and seem “hollow” (see x rays)

- Batch/IC series problem

- Seems to not be the cause, because

- the second DCDC-converter (U300) never failed

- Anyway it may be a problem because

- U300 is loaded differently (and also the layout/location is slightly different)

- Production problem / bad thermal contact on some boards

- Seems to not be the cause, because

- The first 2 x-rays showed no significant difference and looked “good”

- Anyway it may be a problem because

- Only 2 boards were x-rayed so far

- Capacitor related problem (see voltage measurements above)

- Seems to not be the cause, because

- The capacitor(s) should be ok for the given load according the recommendations in the datasheet.

- Anyway it may be a problem because

- The “pulses” on the 5V0_MC output (~100mV) seem a bit too big and are drastically reduced by placing an additional 22uF capacitor

- Note: as 22uF ouput capacitor (C317) “Murata GRM31CR61A226KE19L” are used.

- The datasheet of TPS62133 (SLVSAG7C –NOVEMBER 2011–REVISED JANUARY 2015) indicates in Figure 26, that the “output ripple” should be below 20mV.

- It is though not totally clear what “output ripple” means in this context as e.g. Figure 32 indicates that the “noise” on the Vout is about 100mV (peak to peak).

- The “pulses” on the 5V0_MC output (~100mV) seem a bit too big and are drastically reduced by placing an additional 22uF capacitor

Other information

- A new production batch of the same board is currently in production.

- This new batch is subjected to a “burn-in” test

- In this “burn-in” the boards are powered in an oven at 70°C environment temperature, while loaded with 1.5Ampere (resistive load), during 5x24h.

- So far 2 boards out of 30 showed the same defect (U301 fails) during this “burn-in”