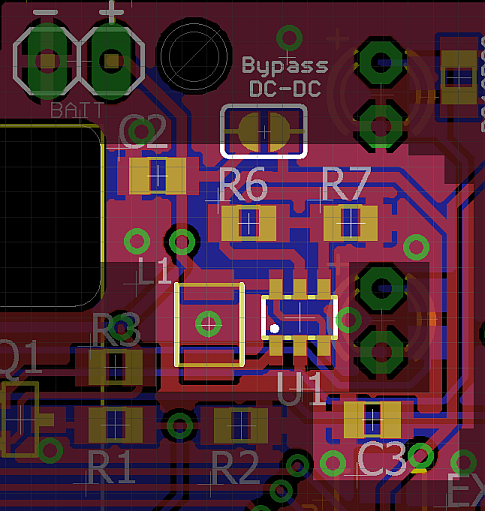

I'm using the TVL61220 boost converter in a battery operated uC/radio circuit (sensor node).

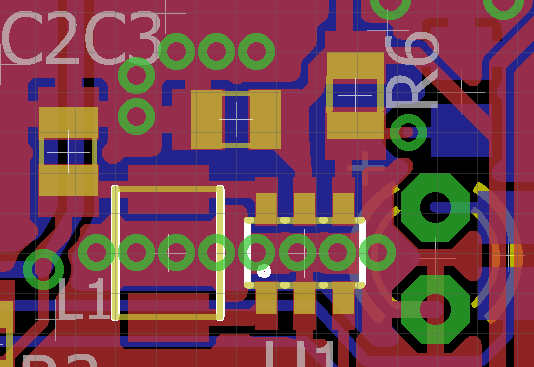

Typically the circuit will be fed using 2 AA cells, but should still operate at a Vbat of around 1v (@Vcc ~3v). The TLV is decoupled with 10uF (X5R MLCC) at the input and outputs, the voltage control divider is 1800 and 360 kOhm.

The circuit is typically at rest, consuming 10's of uA. The other modes are CPU running @ ~3-5 mA and sending a radio datagram the maximum current consumption reaches between 20 and 70 mA.

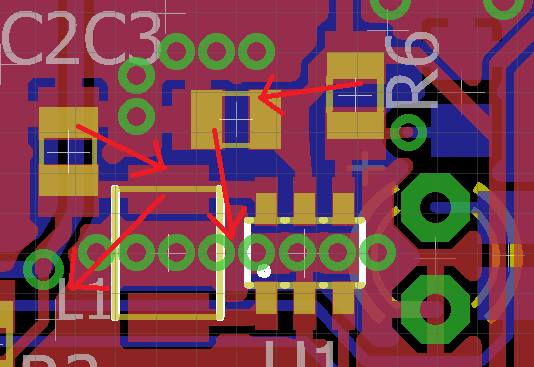

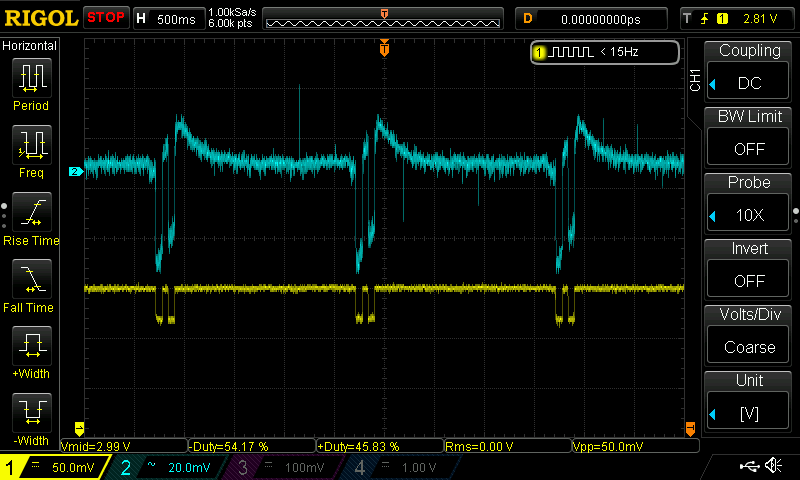

When I power the device using 2AA's (~ 3v Vin), the ripple seems acceptable in the order of 10-20 mV. However when I power the device from a single AA, the ripple reaches about 500 mV (!). Adding additional capacity (additional 47uF at the output) lowers the switching frequency considerable as expected, the Vpp ripple is still > 300 mV accouting for a 5-15% ripple on my Vcc.

Are these normal figures for the TLV61220 and if so, which counter measurements can i take to lower the ripple at low input voltages?

Note that we're still in a prototyping phase, so choosing a different, better suited, switcher is certainly a good/viable option. As always we're aiming for highest battery life (south of 3 years).

Picture shows the Vcc ripple with Vin=~1.5v, standard (2x10uF) decouping and the CPU running (consumption ~4mA)