I've been using the TPS63031 for a while (about 180 devices), and have seen a failure that has occurred several times now, and I'm wondering if it's something in my design.

The symptoms are that total current usage rises to > 200mA and the TPS63031 heats up to about 70C, . The device normally draws around 15mA, and during radio usage, around 30mA.

On a device that has these symptoms, everything is still actually working; the output side of the TPS63031 is producing 3.3 volts as expected, it's just wasting a lot of power and producing a lot of heat. If I power the 3.3v side of the circuit, I see that it is still drawing a small amount of current (around 12mA).

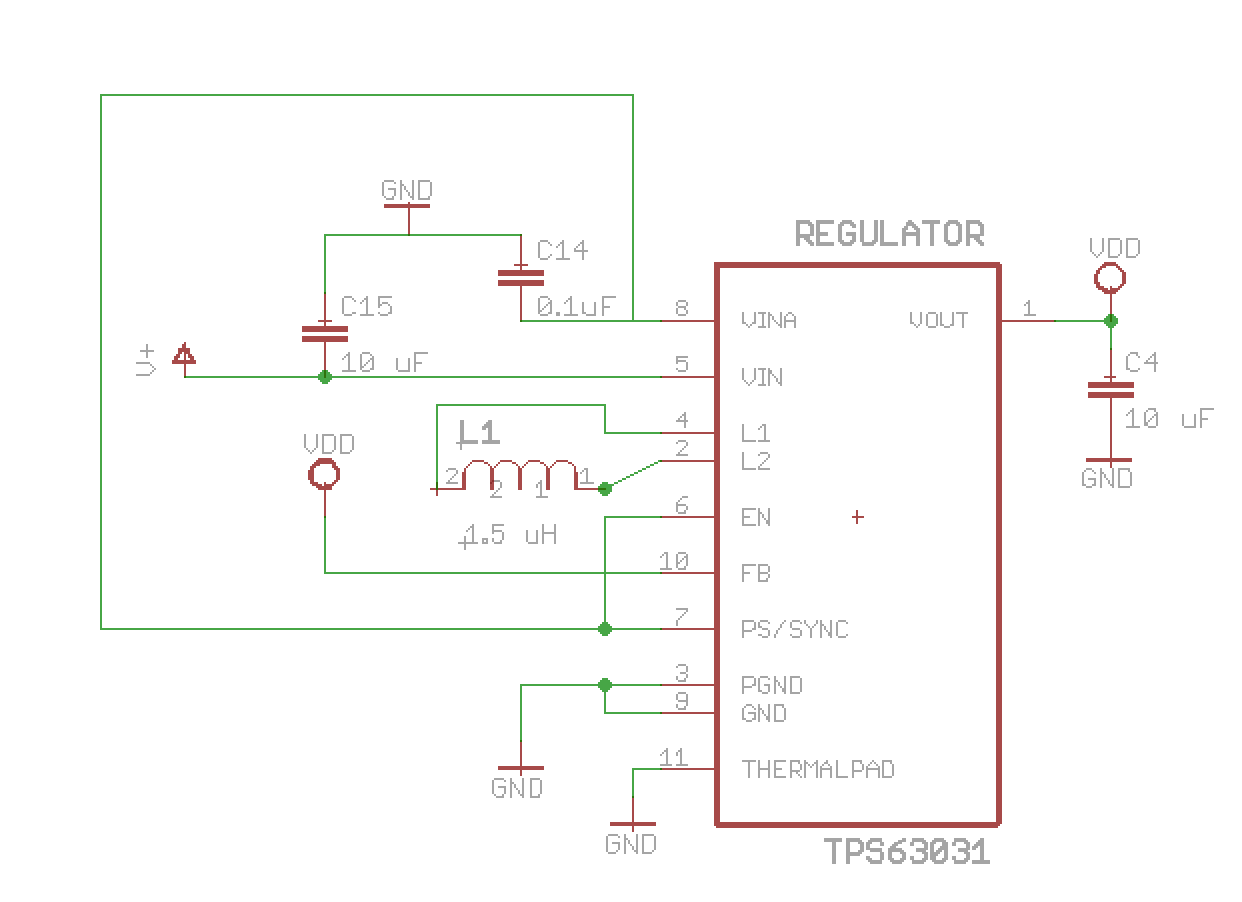

Reading through the datasheet again, I see that I do have the 4.7 μF ceramic input capacitor farther away than recommended; it's about an inch away, near my battery charging circuit. Could that design error cause the TPS63031 to fail in this manner?

I also notice that I have maybe underspecified the inductor, as its limit is 50mA.

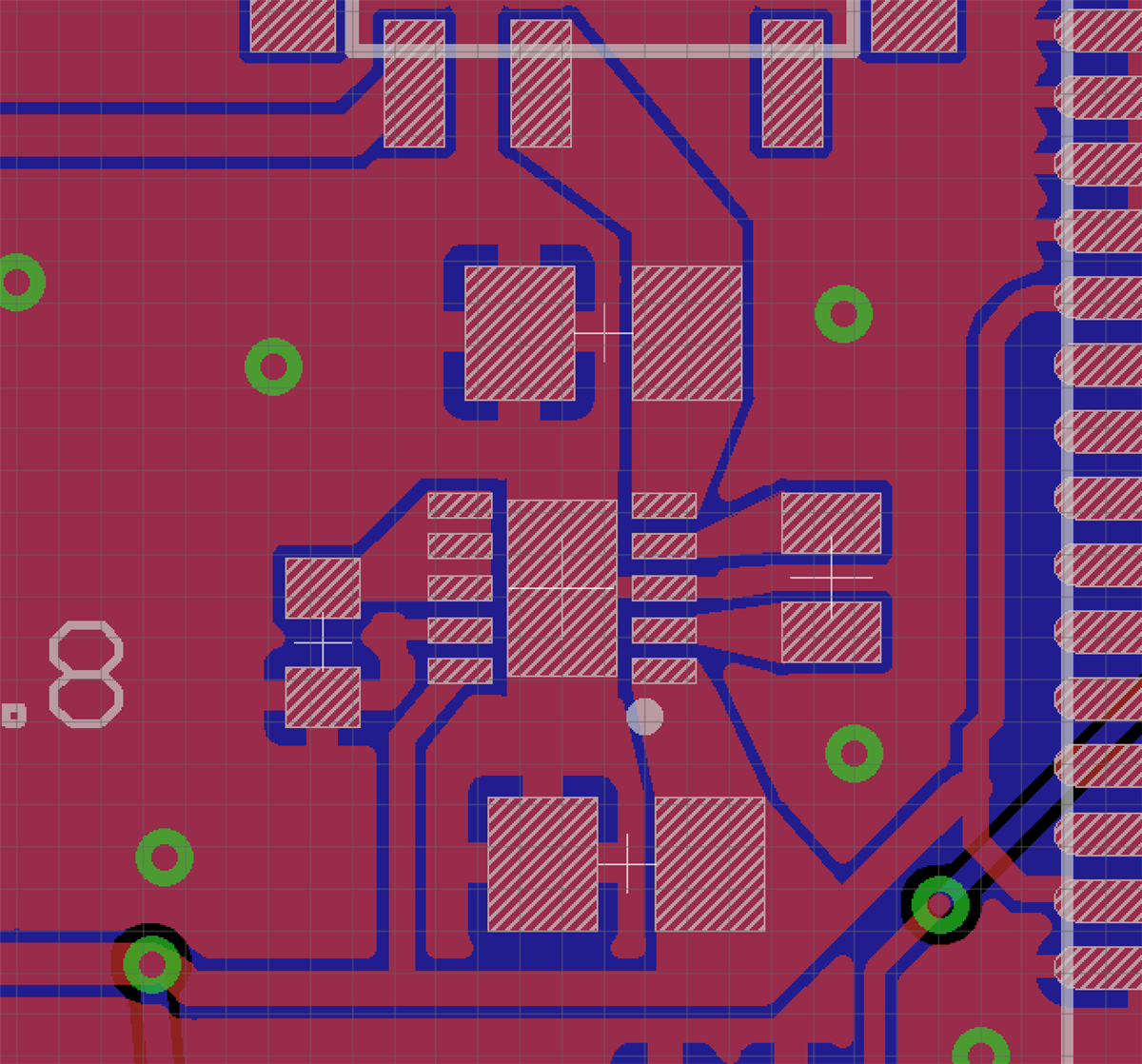

The full design is here.

Appreciate any insight! Thanks!