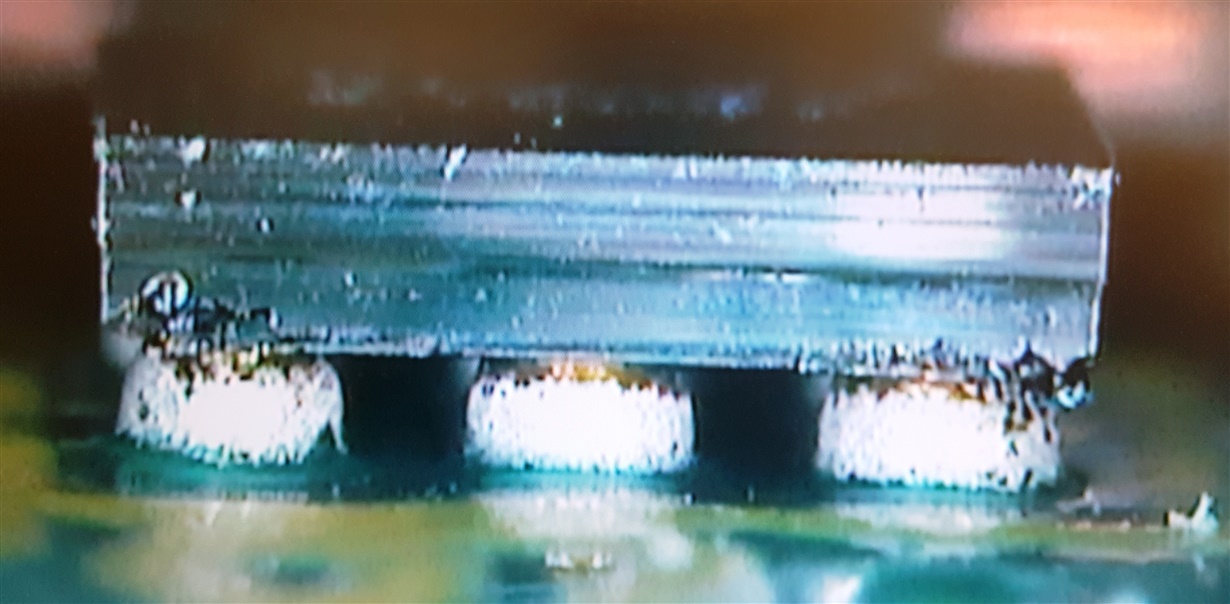

Hello. I'm inquiring about a Load switch. TPS22924 and TPS22920. I work for an electronic contract manufacturing company. I recently assembled a PCB using these SMT DSBGAs using a ROHS process. The customer of this board came back to us claiming that the boards were failing precisely where these components were installed. As I started to investigate our process I noticed that the bodies of these components were damaged. They had crack as if something burst from inside out. The reflow oven profile used to run these boards was tailored for these boards with a peak temperature of 235C. The Datasheet indicates a Peak solder temperature of 260C. These are MSL 1 so moisture wouldn't play an issue. I have pictures of the damage that I would like to share. I'm very inclined to pointing the damage to the design. Can a current or voltage spike break the component body? I would really appreciate your expert feedback. Thank you.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.