Hi Team,

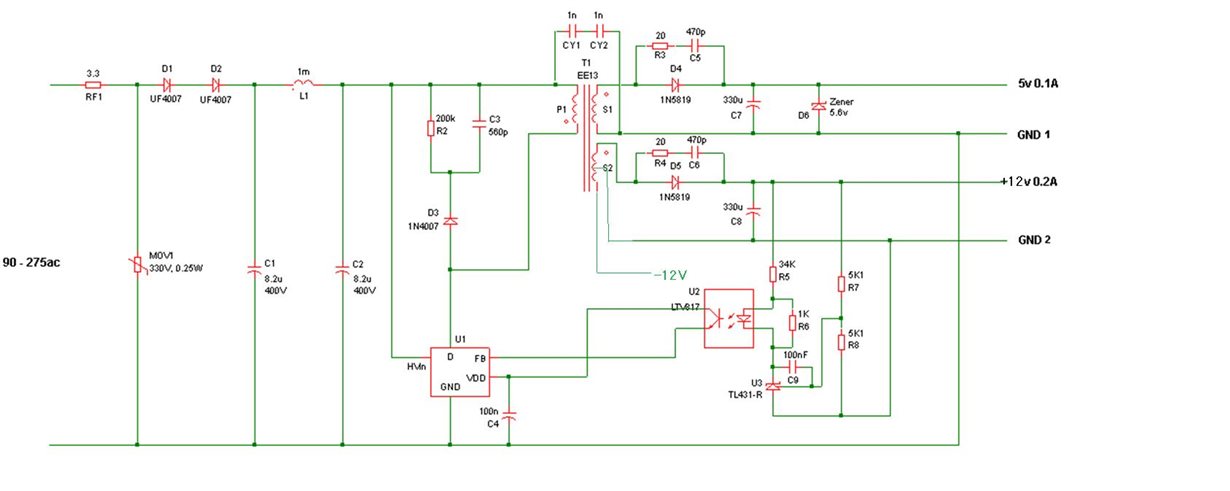

Is there any reference design using UCC28881 to converter 90-264VAC to 5V@500mA in isolated flyback topology?

There is a reference circuit on data sheet page 25 but customer need detail component values and transformer spec.

Thanks and best regards,

Victor