Hello,

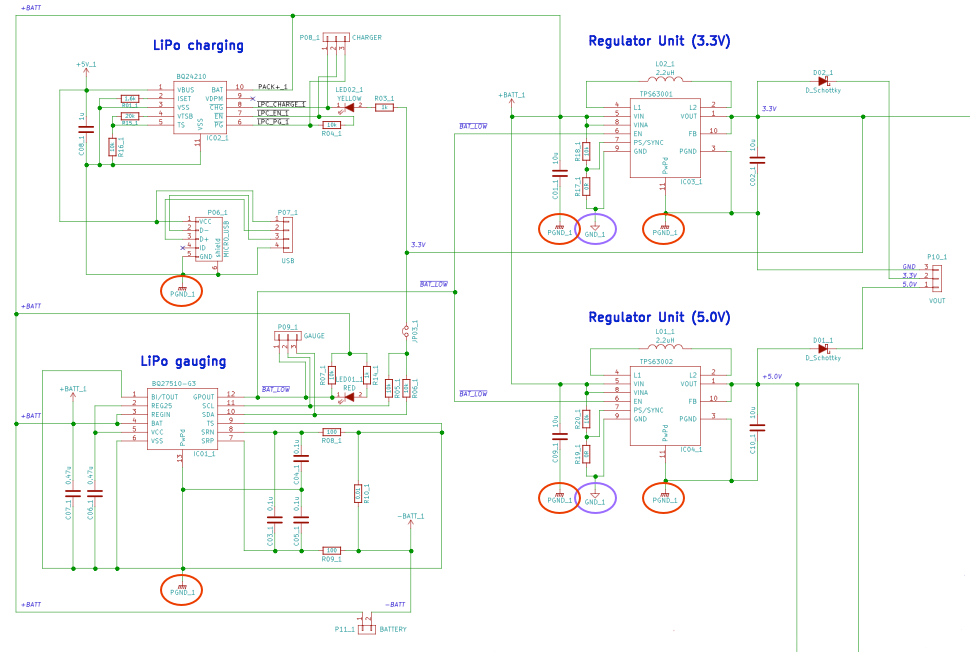

I'm working on a complete charger / gauge / regulator +3.3V and +5.0V design (with the Fuel Tank BoosterPack taking as a working basis).

My questions :

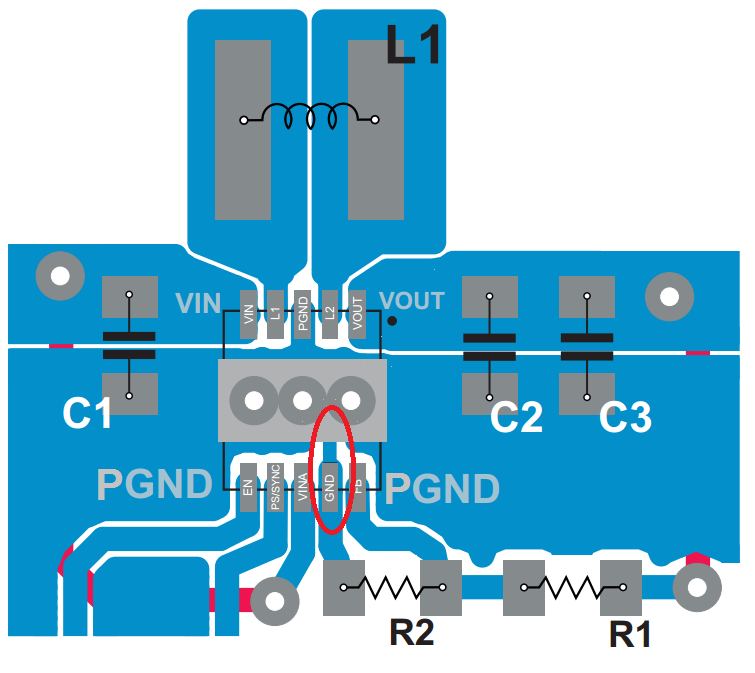

1) I have a misunderstanding between the schema of this card and the recommanded layout in the datasheet of the TPS6300x about the PGND.

It is recommanded to have a power ground different from ground but in the boosterpack schema, GND and PGND are not separated : there's only one ground : GND. Why ? Isn't it a problem ?

2) With Google, i can find schemas with only TPS6300x and good separation of GND and PGND, but i never find schema with TPS6300x integrated in a full circuit (with other functional blocks) with separated grounds. I would like to find a full circuit (or partial schema / PCB) with a TPS6300x, separated GND and PGND, and other blocks as a source of ideas because i don't exactly know how to use this different grounds with my other components (i have LiPo charging and gauging blocks, and OLED screen, microSD card...). Do you have an example of good practice layout like the boosterpack but which respects the datasheets' recommandations ?

Hope my questions are clear :-)

Thank you.

Christophe