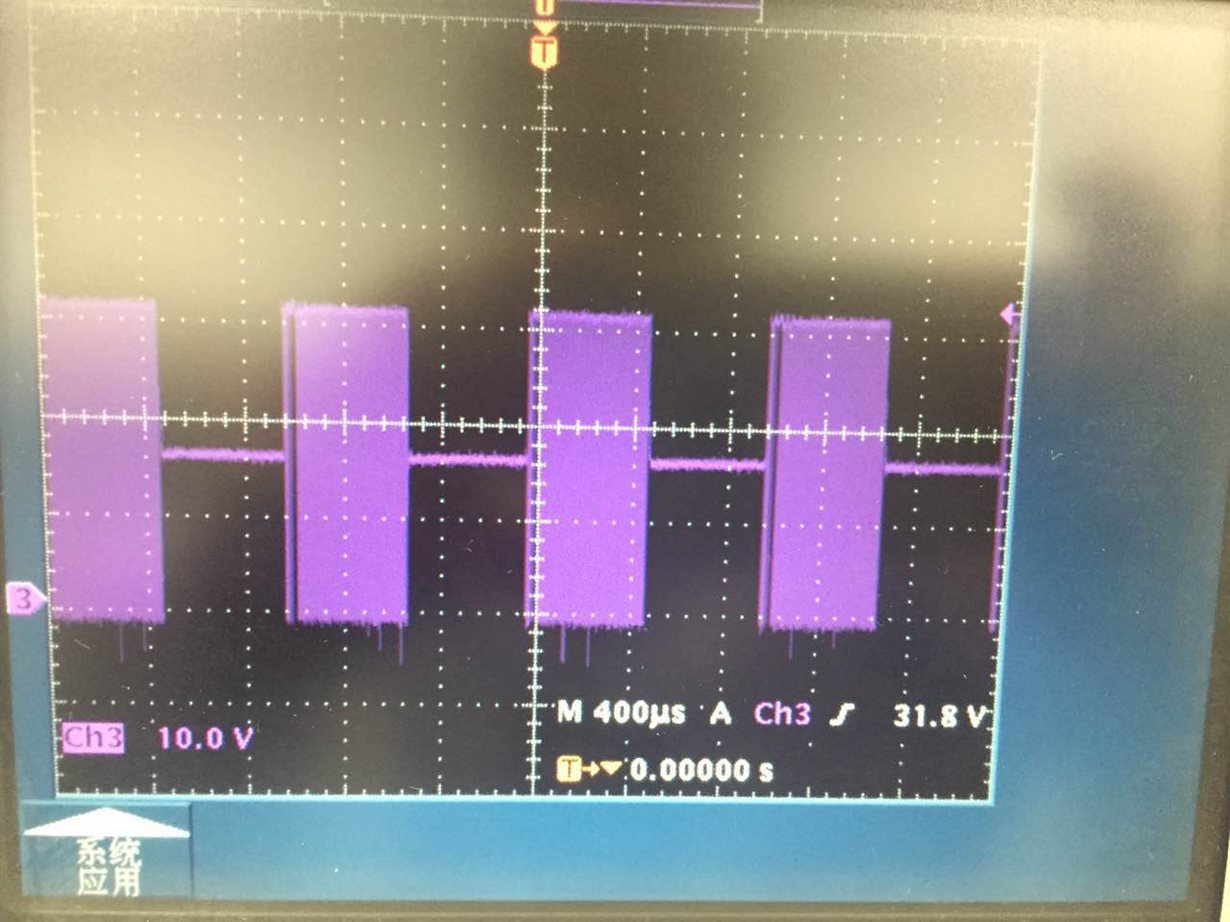

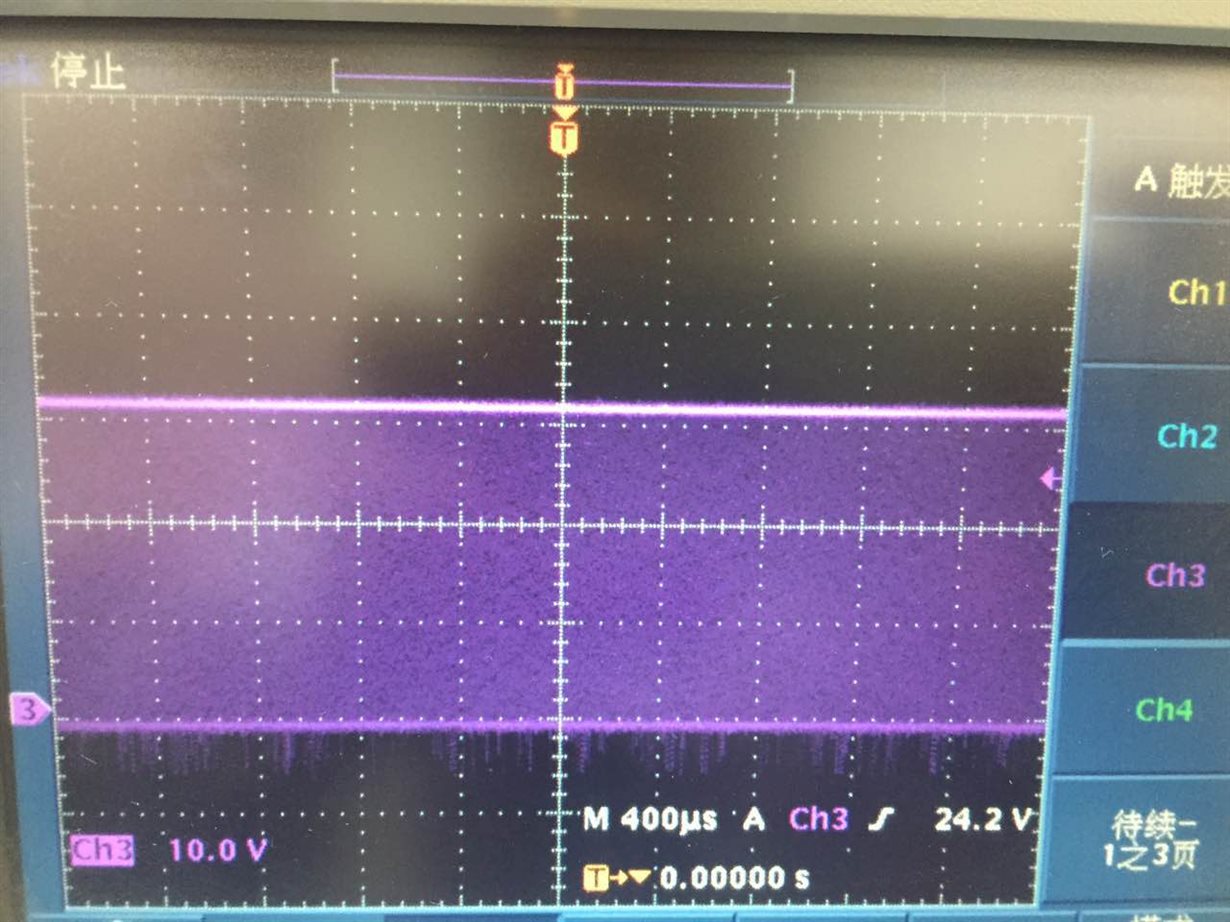

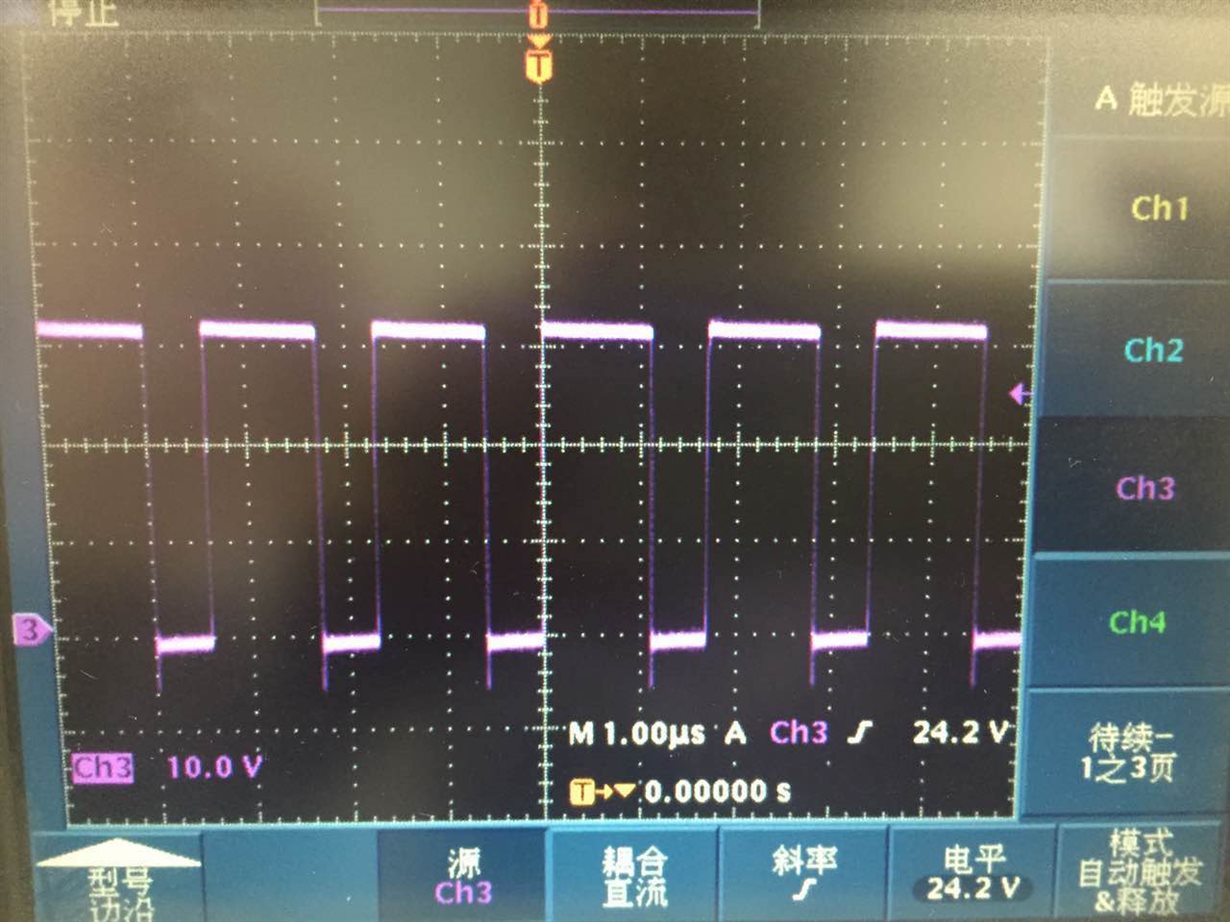

My customer use TPS92641 EVM and they found there has noise when input PWM from in PDIM pin. Only input 100% duty cycle there is no noise. Have you meet this issue in EVM before. Because I don't have EVM at my hand, Could you please check our EVM will meet this issue Or give some suggestion for this issue.

Best and regards

Wentao Zeng