Good day.

As far as I understand, bits 0 / 1 of Chrgr_Reg2 show me state of EN2 / EN1 respectively.

I have tried to config them to 0 / 0 and 1 / 0, but I ALWAYS see there both 0 and 0.

What may be wrong?

Additional question.

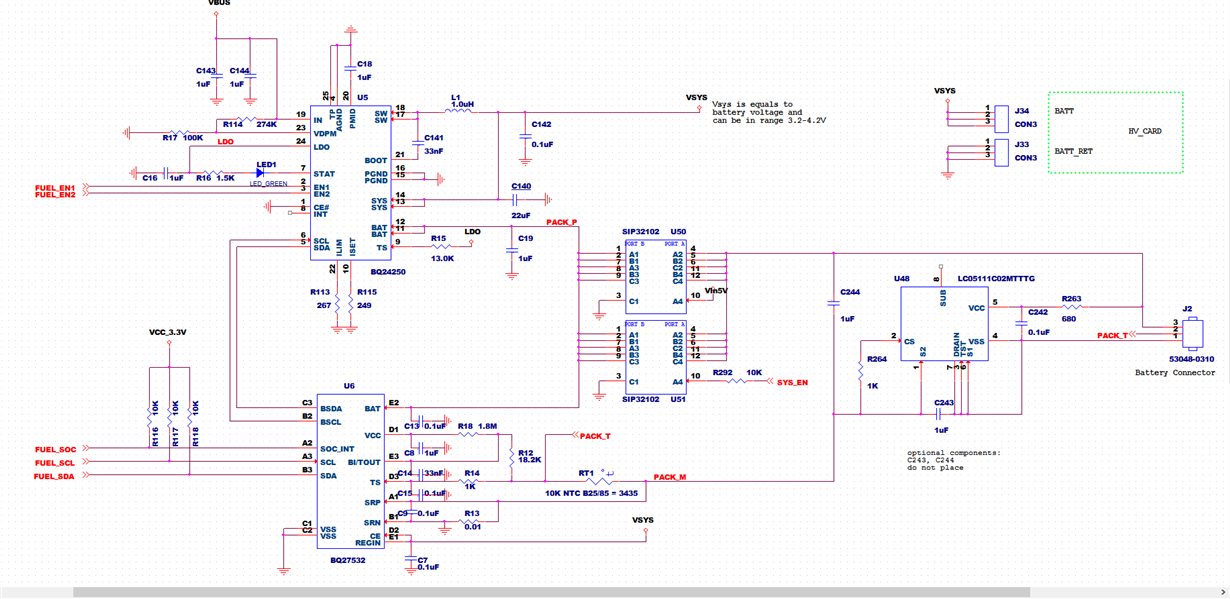

We are using pair BQ27532 + BQ24250. After learning (!)

On the evaluation board I can see charging current 500+ mA.

On the customer board I can see just less than 50 mA.

What may be wrong?

Thanks.