Other Parts Discussed in Thread: TPS61030, TPS61235P, TPS61236P

Hello,

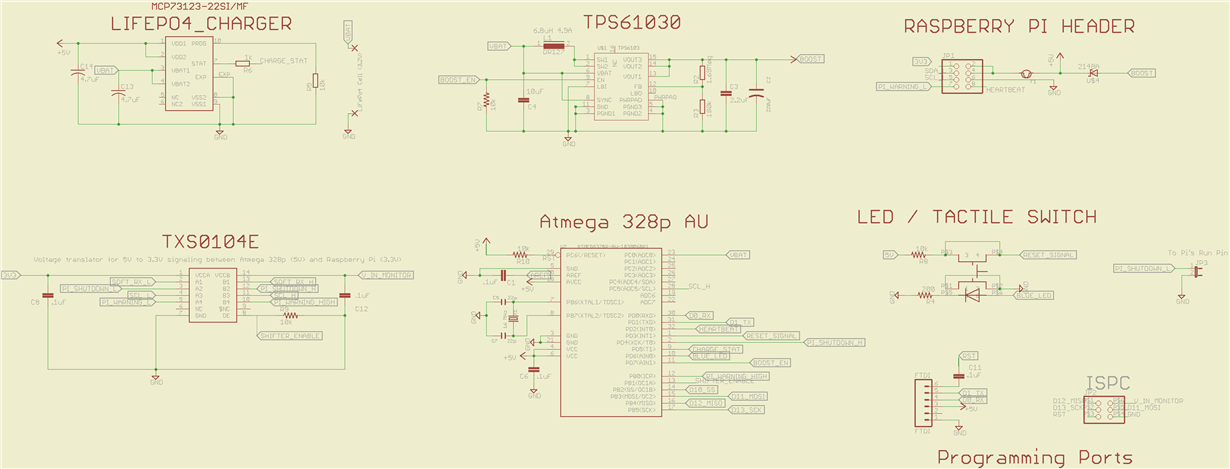

I am trying to create a battery backup system for a raspberry pi model 3. We are creating a player for digital signage application and knowing common issues of SD card corruption due to power outages. Anyways the basic circuit is an MCU to manage battery voltage, button interrupts to signal shutdown. We are using a 400mAH LiFePo4 battery for the backup supply that is charged via microchip's MCP73123. The basic requirements of the boost circuit is to increase voltage from 3.2 V to 5.1V for the Pi. Max load current is 1.2A with transients up to 3A. I have had several of these TPS61032 fail catastrophically (burn up) while in operation. I'm wondering if someone can point out a fundamental flaw in my circuit design. Note that the TPS61030 defaults to disabled via a 10k resistor to ground. The MCU gets power as soon as the Pi is powered via the pi's micro usb power supply. The MCU first analyzes the battery voltage and enables the boost converter if Vbat is above 3V. After the boost circuit is enabled the MCU allows the Pi to boot up after Vbat reaches 3.3V. In the case of a power outage the boost circuit supplies the 5V and the MCU monitors the battery voltage as it drains. If the Vbat drops below 3.1V the MCU signals the pi to start shutdown. After the MCU confirms shutdown the MCU disconnects the boost circuit after Vbat reaches 3V to prevent unnecessary drain.

Thanks!