Other Parts Discussed in Thread: BQ76930, BQ78350, , BQSTUDIO

Greetings

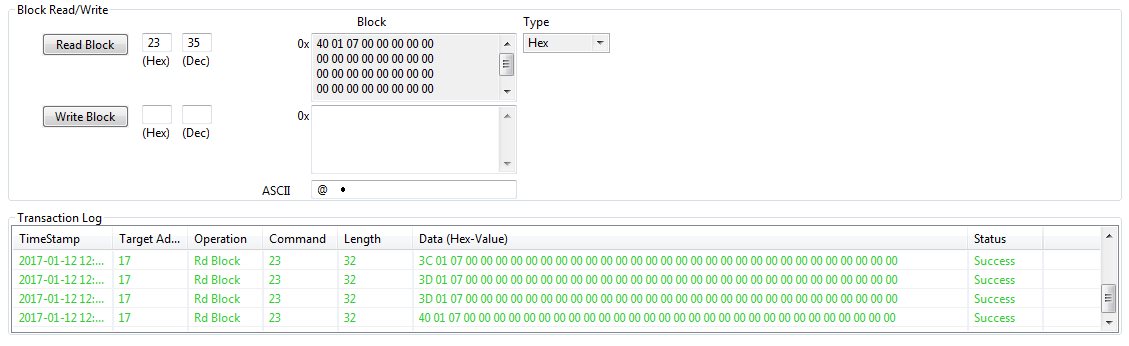

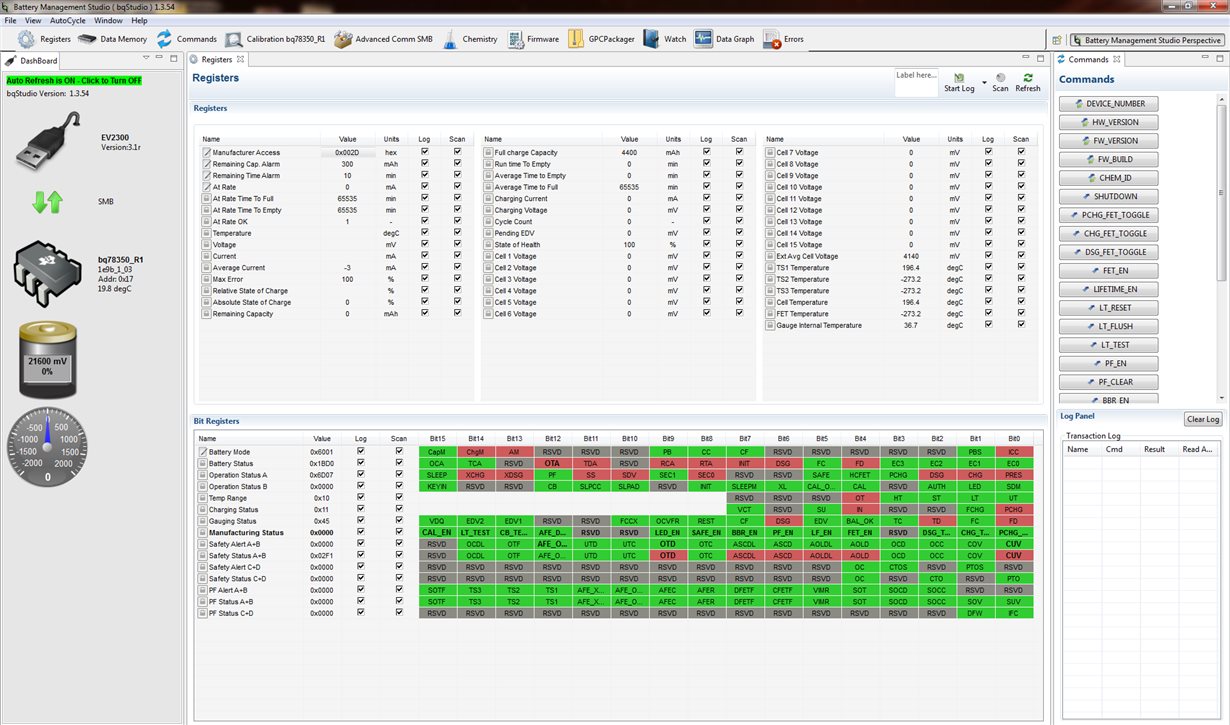

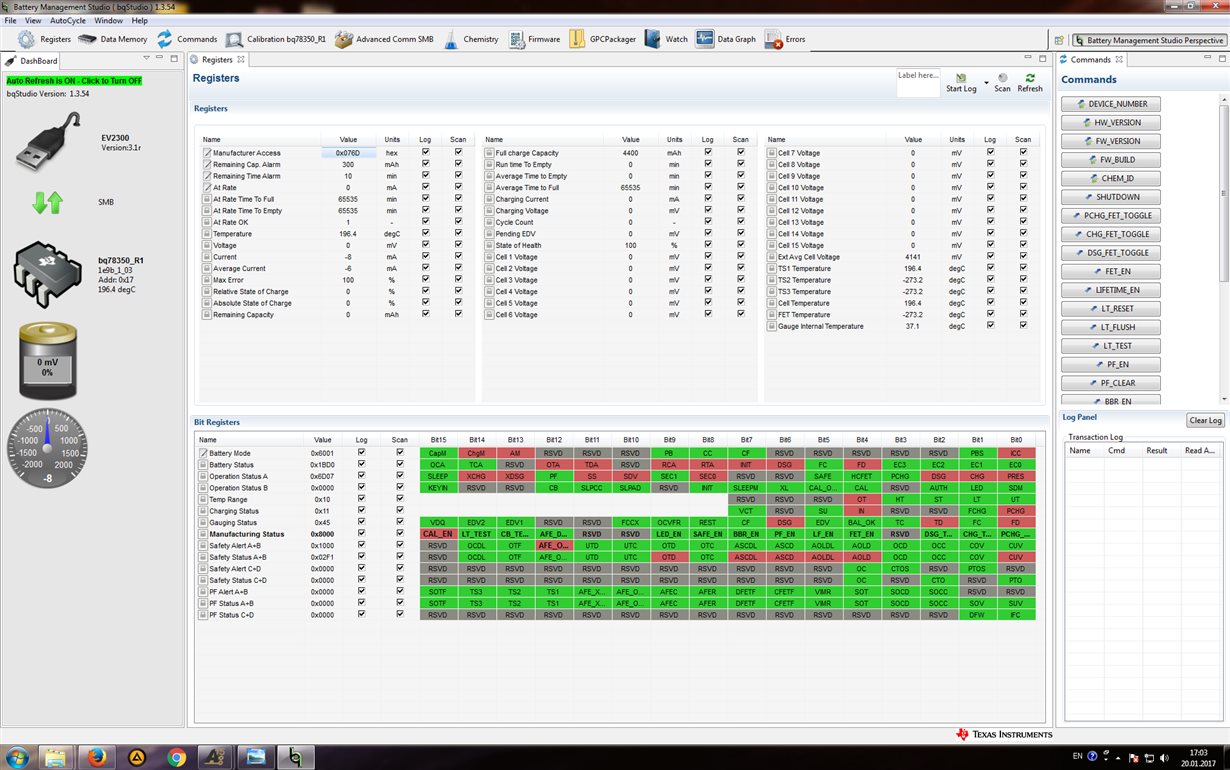

So, I'm trying to calibrate my BQ78350-R1 using Battery Managment Studio, but i've confronted problem.

While reading ManufacturerData() I can't properly read any cell voltage. All I get is zeros at any cell, what in fact is wrong. Where could be a problem and how to solve it?

I attached screenshots to show my situation.

Thanks for helping

Anton Kanyshev