Other Parts Discussed in Thread: BQSTUDIO

Dear all,

I designed my PCB (portable device, 1 Li-Ion cell of 3.7V, 1100mAh) with the gas gauge BQ34Z100-G1. I followed the instructions from the document SLUA334b.pdf (with close Qmax value) and I made 4 cycles so far but the "Learned Status" is still at 0x04 and the MaxError is still at 100%.

I always respected the relax times... I did the calibration (Voltage, Current, CC offset and board offset).

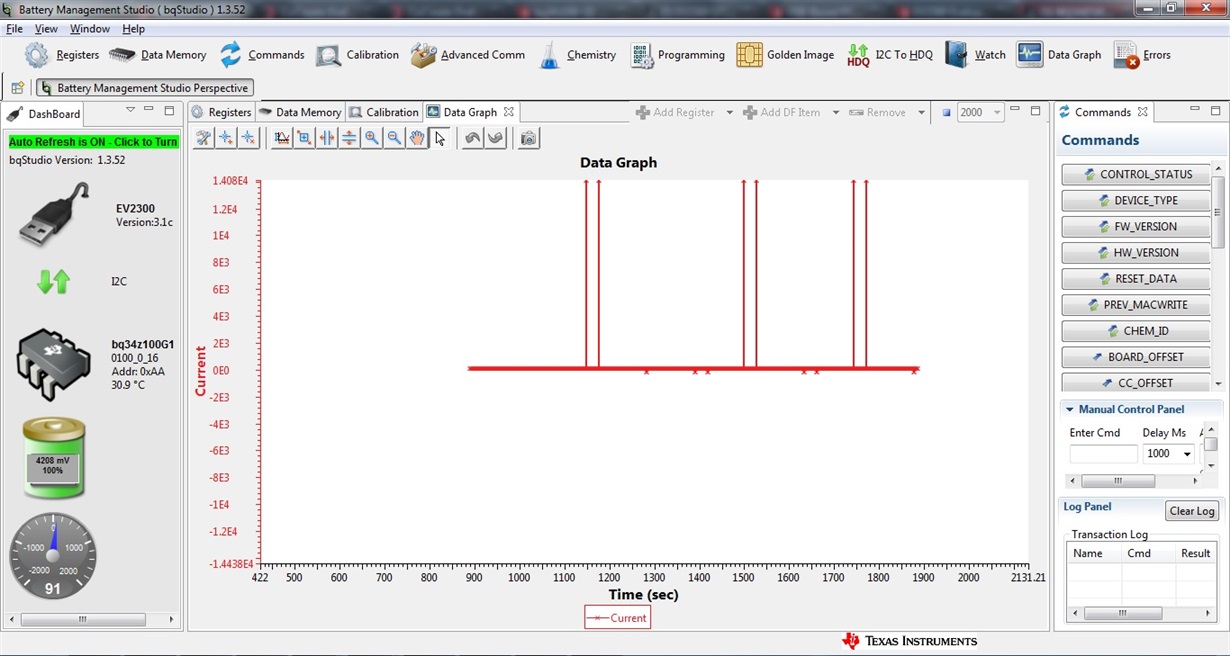

What I noticed is sometime, when my circuit is idle, I saw the current going to -1ma (which is very low but the current consumption should be 0mA when my circuit is idle). Do you think I can have a CC offset or board offset issue? As well, I put the deadband current to 1mA (now 2mA), would it be a problem for the learning phase?

Moreover, I use a protection circuit (BQ29700) that switches the MOSFET off when the battery voltage drops below 2.8V and I always wait on this event. This could be another issue or is it OK ?

Best,

Christian