Our customer consider to use LM53635LQRNLTQ1(5V fix version).

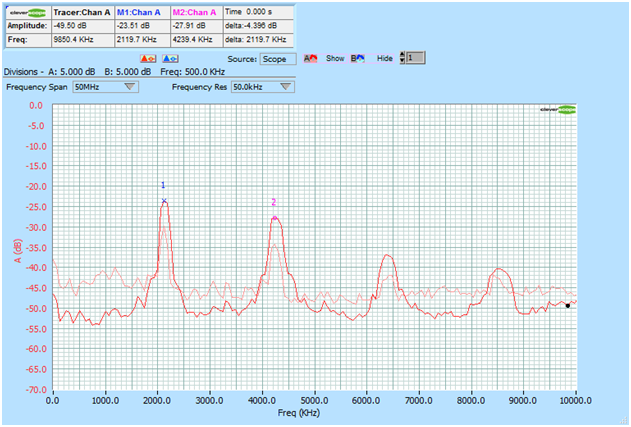

They check EMC test (CISPR25 2002) on their board

Result is:

PK:30dBuV

AV:26dBuV

Limit is 18dBuV (So this is 12dB over)

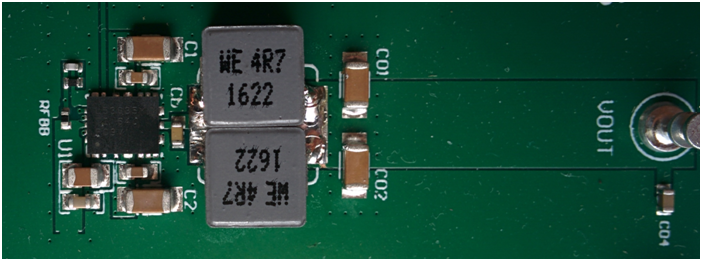

This case their output L,C is Inductor:2.2uH, Capacitor:22uF x 3pcs

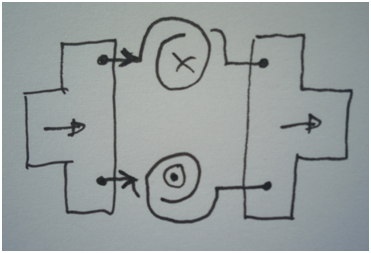

They would like to minimize ripple current about 18dB(include margin) to meet EMC requirement.

But this case is that Inductor value need 22uH.This part can use inductor from 1.5uH to 10uH in datasheet.

If you have solution or idea to meet their EMC requirement using with LM53635LQRNLTQ1,please let us know it.

regards,