Other Parts Discussed in Thread: BQ25504, BQ25570

Hi,

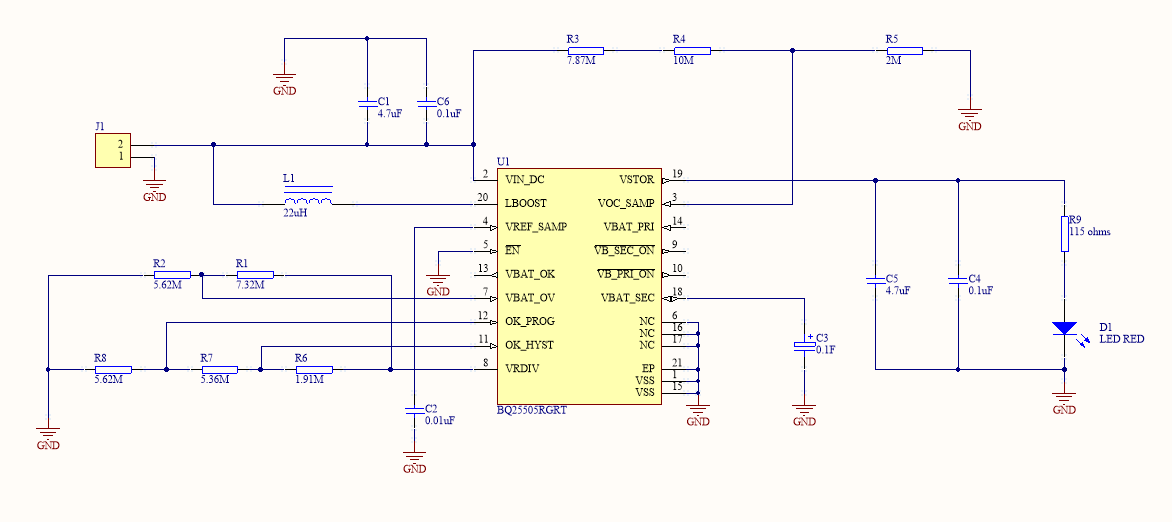

I'm trying to design a boost convert/charger for DC-DC low voltage system. My energy harvester is a Plant Microbial Fuel Cell and I'm trying to design a boost converter/charger that can increase the input current from microWatts to milliWatts. I'm not really sure if bq25505 is the correct IC for me to use. The Plant Microbial Fuel Cell produces 50mV - 200mV with a current of 50uA - 200uA given the external load is 1000 ohms. I want to boost the power output to supply a load. I'm still deciding on what load will be suitable. I'm deciding between a mobile phone battery or a set of LEDs connected in series.

I'll really appreciate it if I can get some help figuring all this out. I'm only a student and this is my first time in designing something like this and I'll need all the help I can get.

Thanks you.