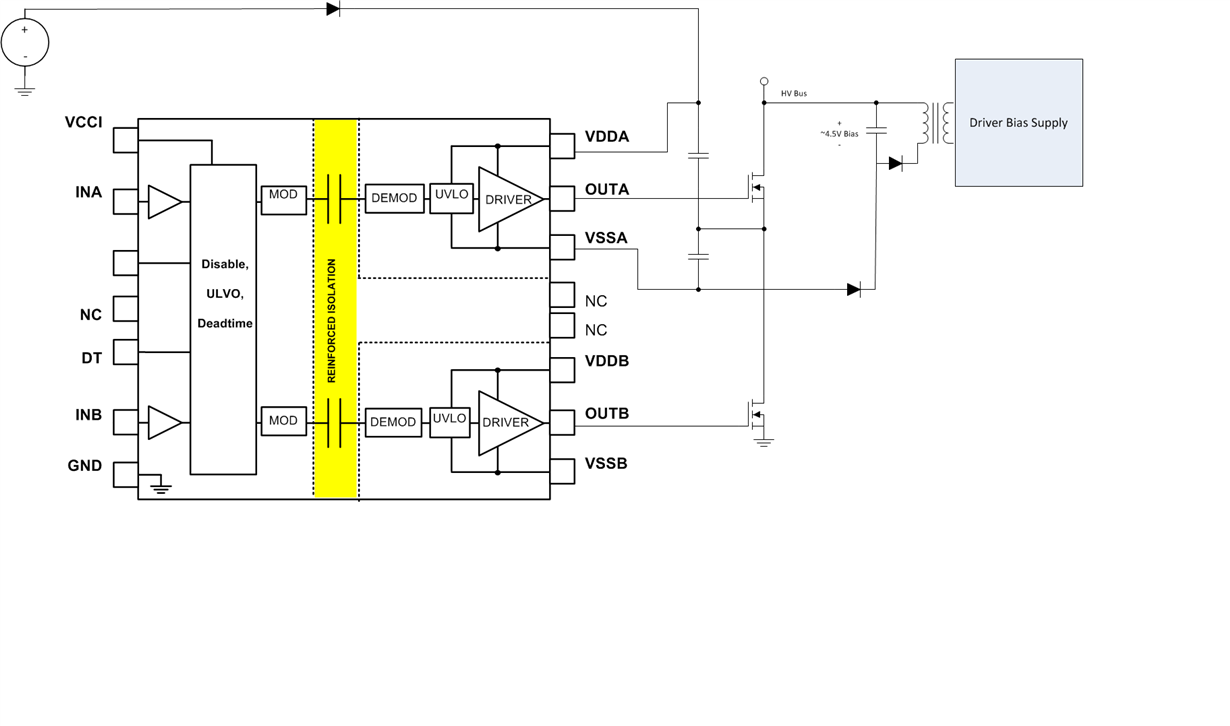

Currently, I am working on a SiC half bridge circuits, and trying to use bootstrap power supply instead of isolated supply for highside and lowside switches. But it seems that the implementation of the -5V turn-off for highside switch is an issue.

Can someone give me some hints to solve this problem?