Other Parts Discussed in Thread: INA240

Hi guys

Recently we developing a new stepper motor driver using LM5106 and Mosfet H bridge configuration. I have to mention we have to lunch the new product by July so any help will be appreciated.

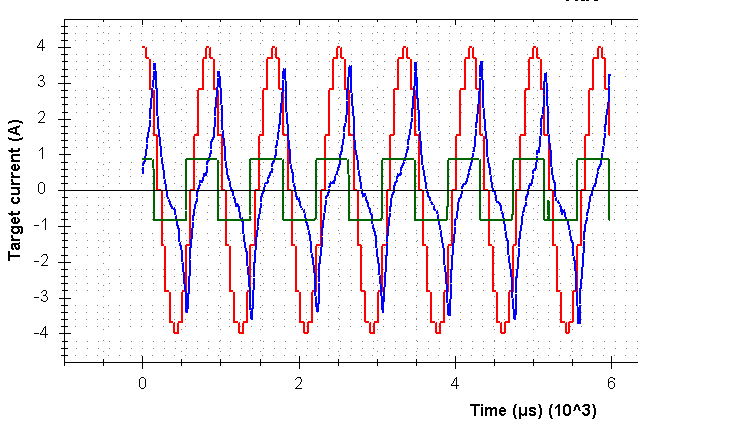

The issue is I have wired current output at speeds higher than 420 RPM above. Please have a look at the following picture.

the Red line is our micrsoteping output which feeds to the PID refrence, the blue line is current output out of shunt resistor. green line is output of PWM. PWM 1 means 100% in forward direction and -1 means 100% in backward direction. as you can see my PWM reach to maximum but still the desire current is not being achieved. I know this is due to back EMF stuff, still the shape is not very logical to me and I m not able to explain it.

the Red line is our micrsoteping output which feeds to the PID refrence, the blue line is current output out of shunt resistor. green line is output of PWM. PWM 1 means 100% in forward direction and -1 means 100% in backward direction. as you can see my PWM reach to maximum but still the desire current is not being achieved. I know this is due to back EMF stuff, still the shape is not very logical to me and I m not able to explain it.

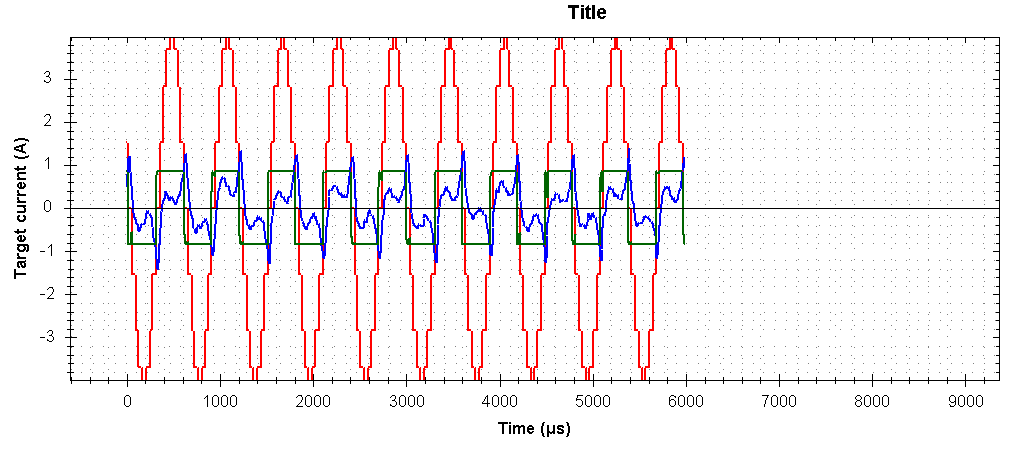

however at lower 300RPM I get something way more meaningful please have a look at the following picture.

although the feadback current due to inductance is messed up but still is acceptable.

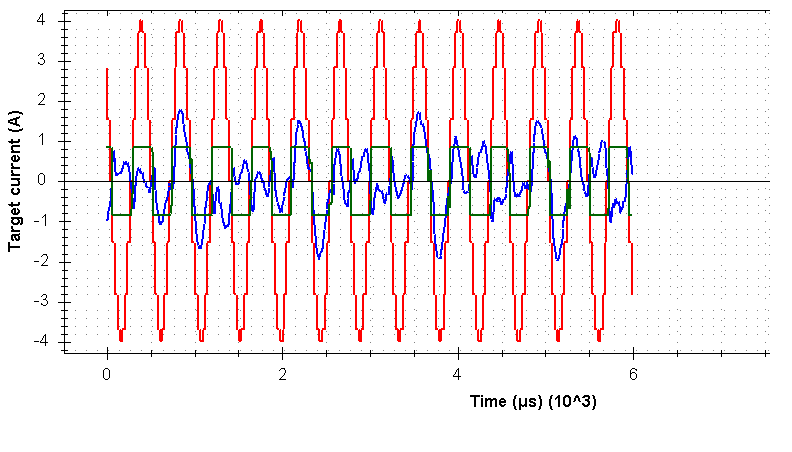

if i go for higher RPM the graph get worst. the following graph catured at 600rpm

If I go a bit higher RPM than this the motor stall.

If I go a bit higher RPM than this the motor stall.

So I wonder if anyone could help to explain the graphs , and even it would be better if someone could help to solve this problem.

For your info

- the Vbus voltage is 24 volt --> I cant change power suplly source due to cusstomer specefication. however I have tested the 48 volt which obviously give much more decent output due to better ability to overcom BackEMF voltage

- the motor inductance is 2.1mh

- the resistance is 1.1 ohm

- the motor rated current is 4.0 A/phase