Hi

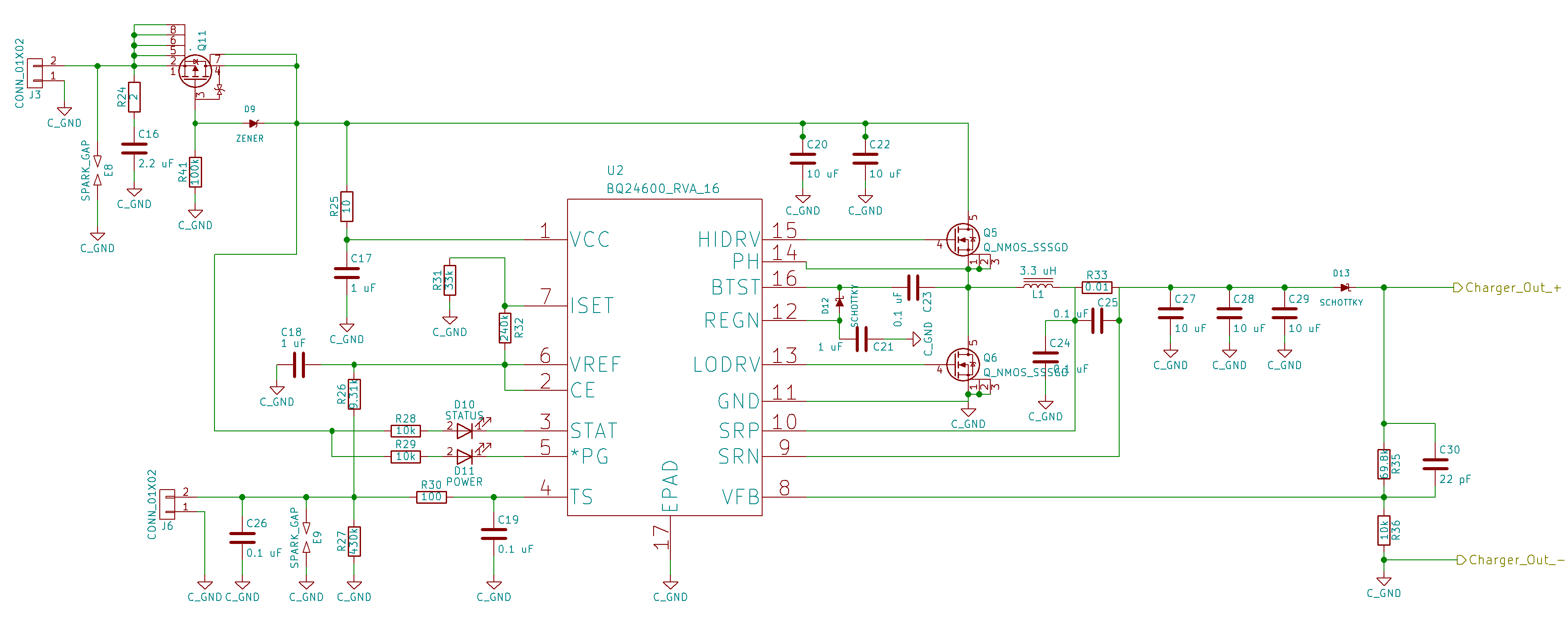

We are building a 4S (16.8V), 2A charger for a LiPo battery using the bq24600.

We had problems with the reference design as per the bq24600 datasheet: The PCB failed catastrophically from high inrush current when the battery is connected. From other post on this form it seems that several other users experienced a similar problem.

We solved the inrush current problem by simply adding a schottky diode (D13) in the output path of the charger as per the attached schematic.

However, our charge current is measured at around 1.7A and not the desired 2A as was designed for.

Thus, will the addition of the output diode affect the internal regulation of the bq24600 to explain the charge current difference? If so, what will be a possible solution for accurate charge current with inrush protection?

Thanks,