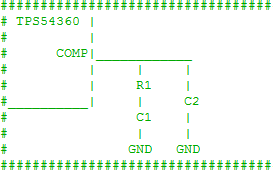

Other Parts Discussed in Thread: TPS54360, TINA-TI

Tool/software: WEBENCH® Design Tools

Hi,

I would like to design a circuit as small as possible by increasing the frequency. However, when I increase the frequrncy using WEBENCH tool, the automotive grade TPS54360-Q1 disappears from the list. and nothing shows up at 1500KHz although they can go up to 2500KHz.

Anyone have any idea what is going on here? How can I test the circuit with such purpose?

Any helps or comments are appriciated.

Regards,

Ogulcan