Other Parts Discussed in Thread: TPS61088

Hi,

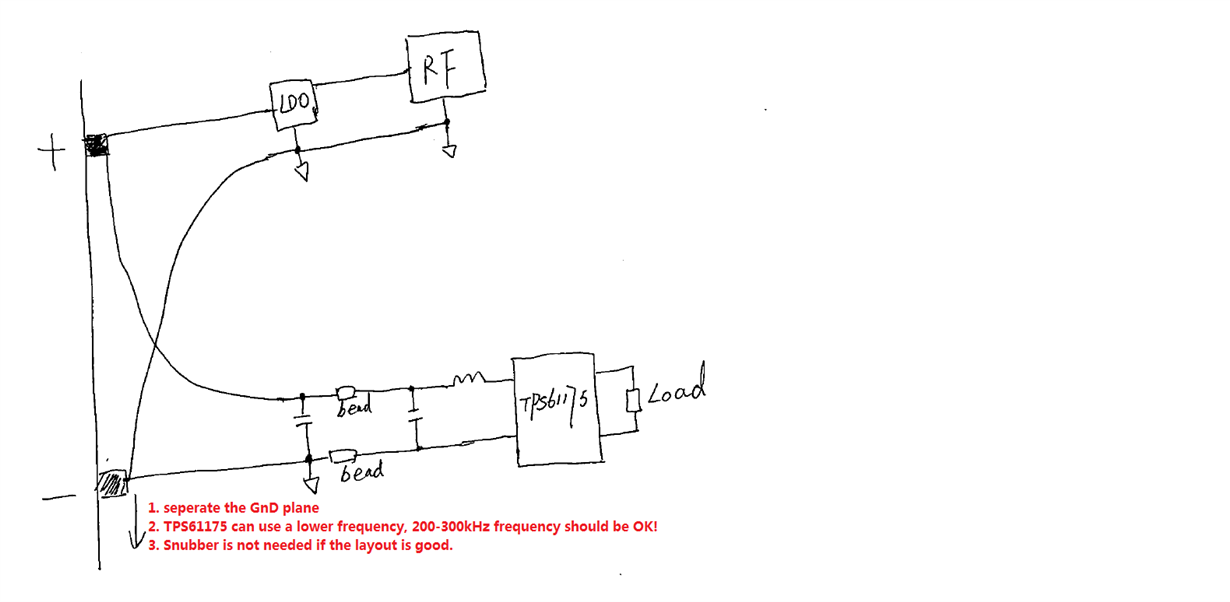

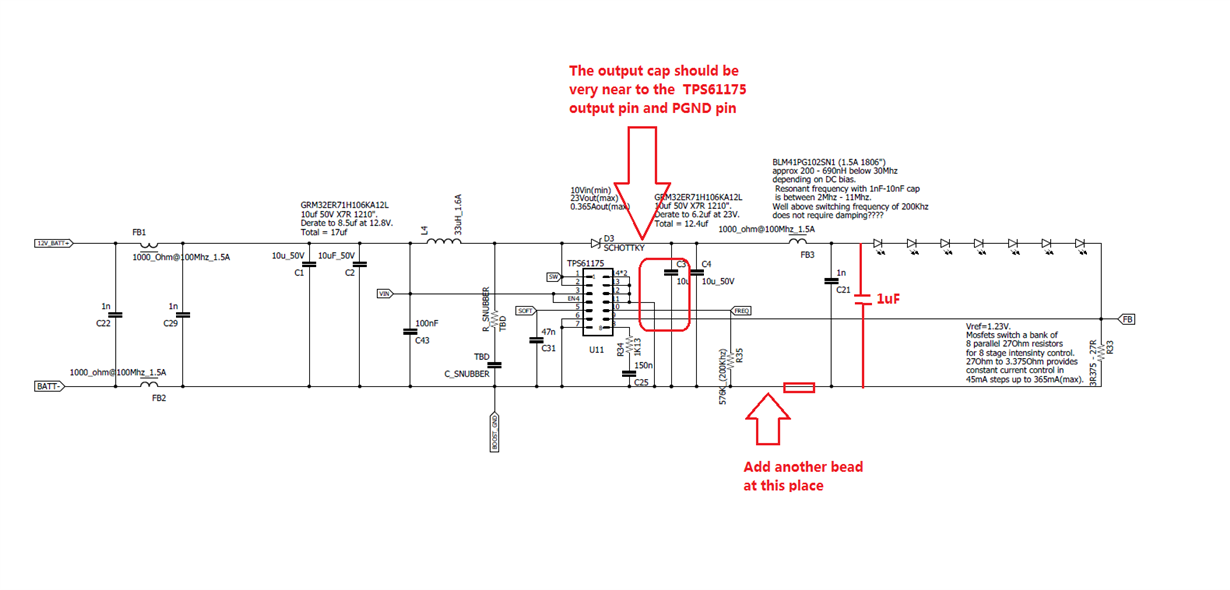

I am designing a 4 layer board with a TPS61175 boost converter (10V to 22V, 350mA load), the board also has an RF transceiver at 120Mhz (not part of the load). I'm trying to reduce the interference of the boost converter on the transceivers performance. Would it be worth considering the inclusion of an RC snubber between the switching node and ground to reduce harmonics, or is it not recommended with TPS61175?

Also, would separate ground planes a good idea?

Regards

Matt.