Other Parts Discussed in Thread: LP2985,

I'm having some issues with this part not switching on startup. I'm using two of these to form an H bridge for bipolar control of a TEC element.

My setup:

Vdd = 5V, Vin = 3V

Skip# tied to Vdd

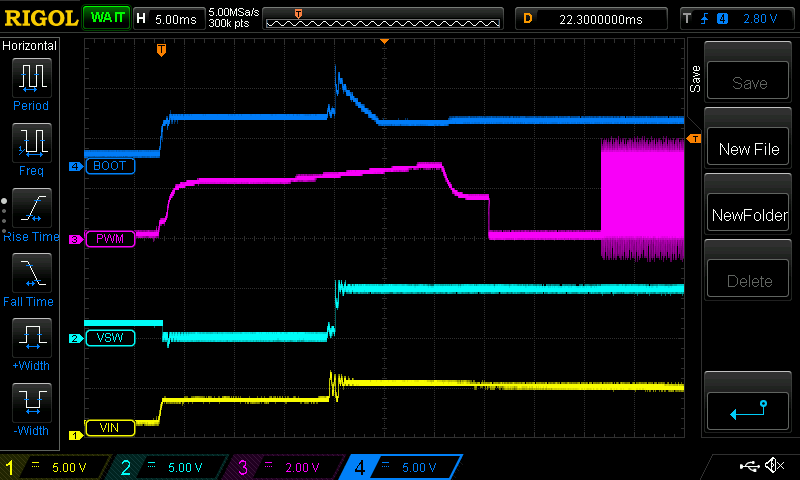

Bootstrap capacitor is 0.1uF with a 2.2 ohm resistor to slow down the switching times

I'm using a microcontroller (Cypress PSOC 5LP family) to drive the PWM pin.

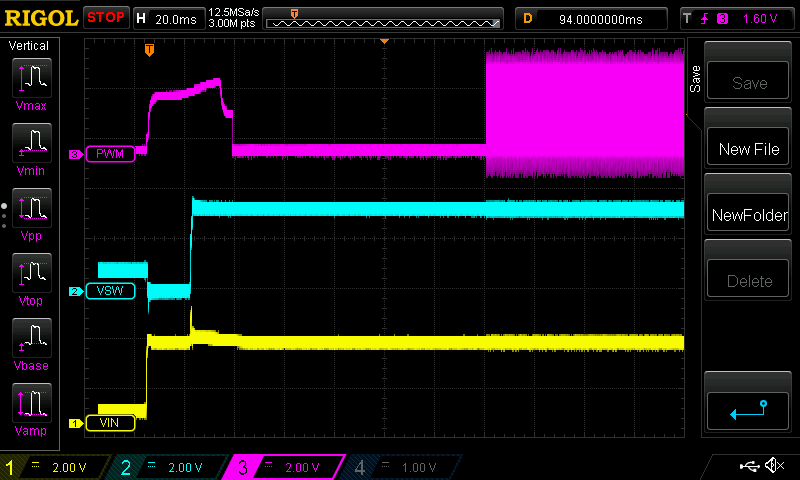

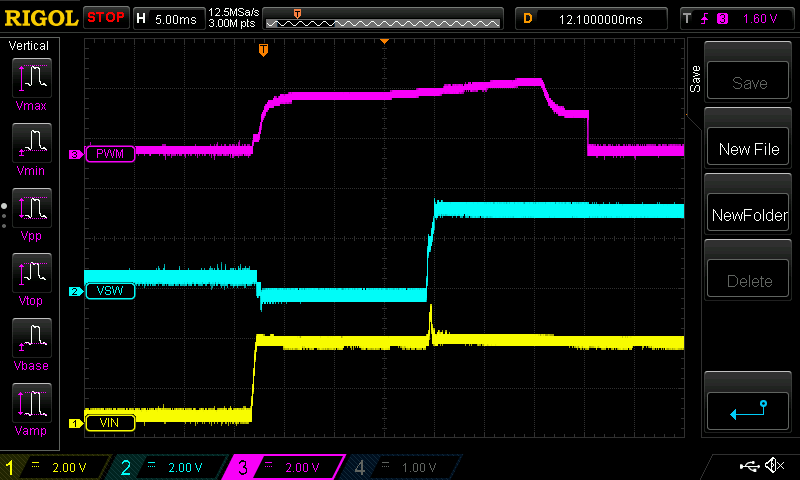

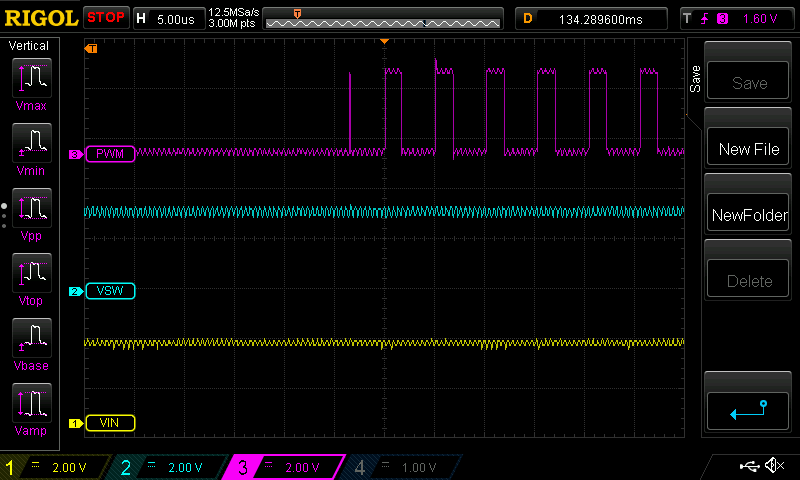

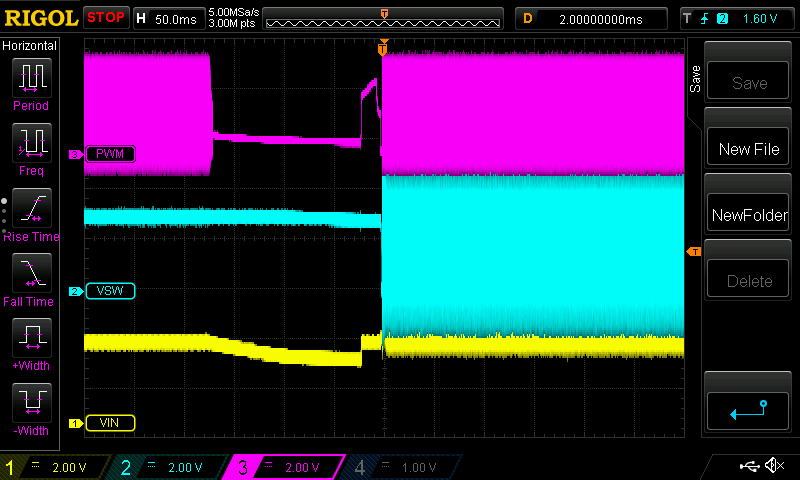

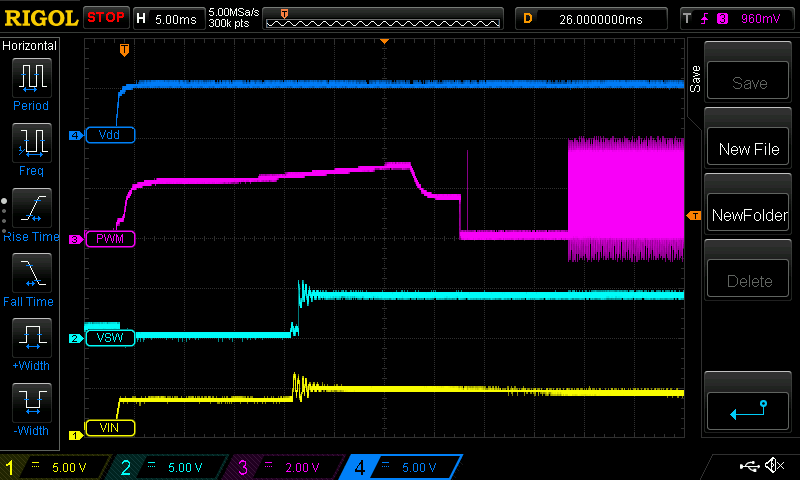

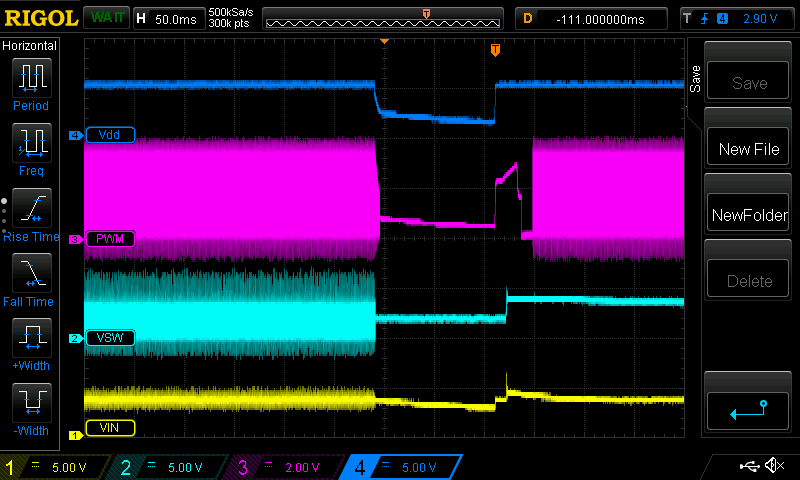

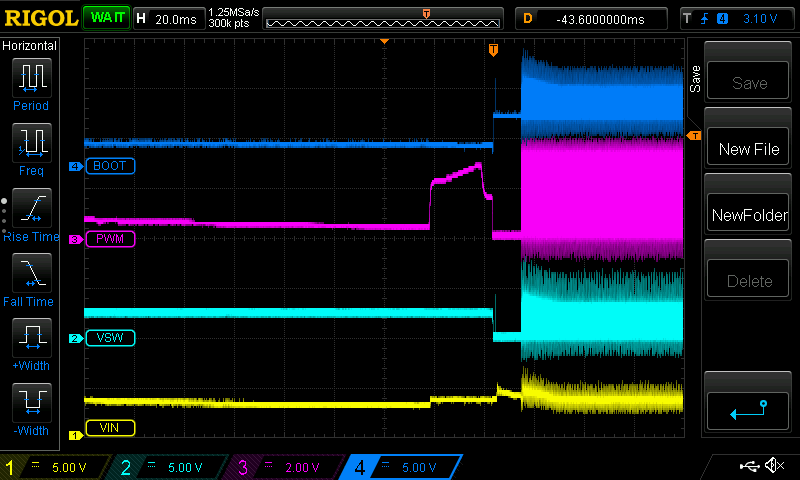

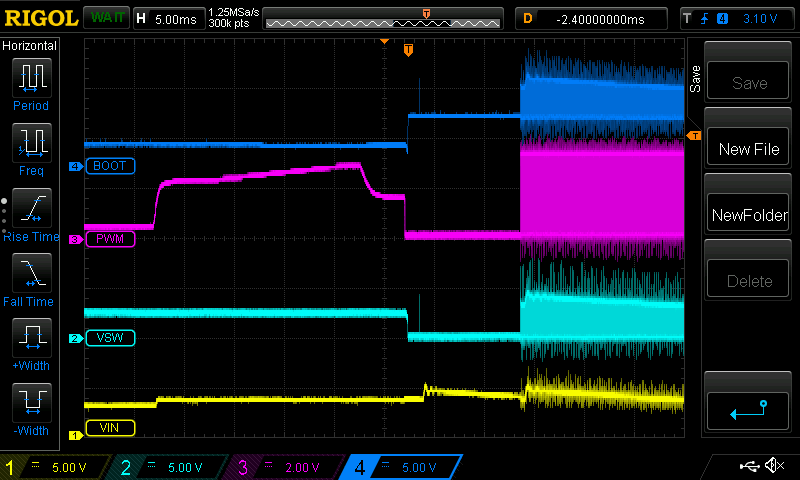

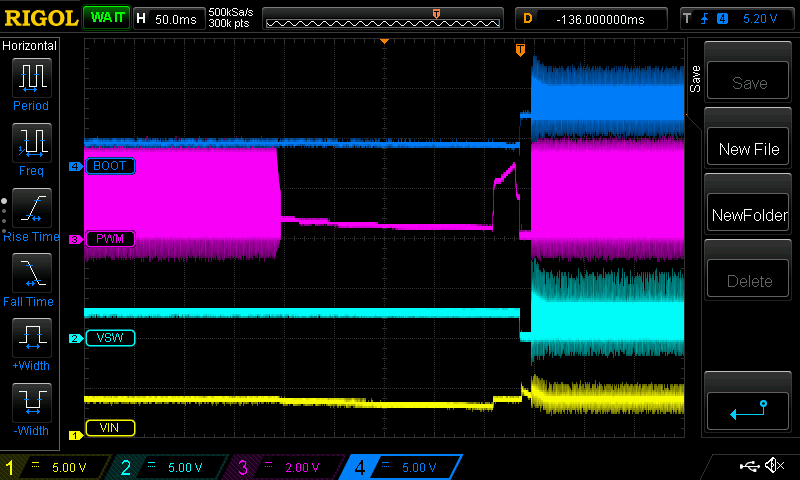

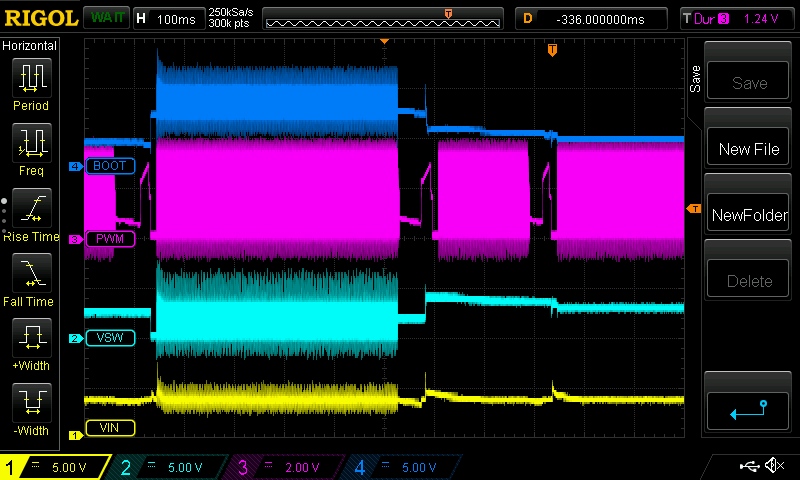

The symptom is that when I first apply power, the Vsw node goes high and does not change no matter what pulses I apply to the PWM pin. The only way I can get it to start switching the Vsw node is by briefly interrupting the power to the board - if the interruption is short enough (maybe 0.1-0.2 s) then it will start switching and operate normally.

The Vdd supply comes up very quickly. The microcontroller takes a little more time to initialize. I can see the PWM pin float at first before the microcontroller comes on line. After that, it doesn't seem to matter what I do to the PWM pin - high or low level, high or low frequency.

Any help would be most appreciated - I'm working on a prototype and I don't think a user instruction to "jiggle the power cord" to get it to run will be well received.

Thanks!