Hello,

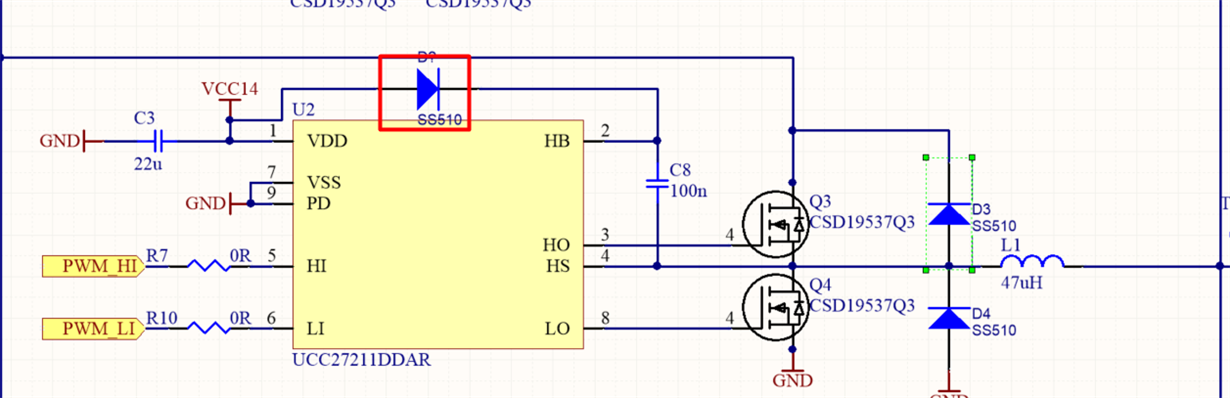

See my circuit below,

I'm seeing high temperatures with minimal load on the mosfets (few watt's). When I turn up the load the mosfet driver keeps getting hotter and hotter until it gets too hot and shuts down.

I have seen case temperatures of 100 degrees Celsius +.

My application is as follows:

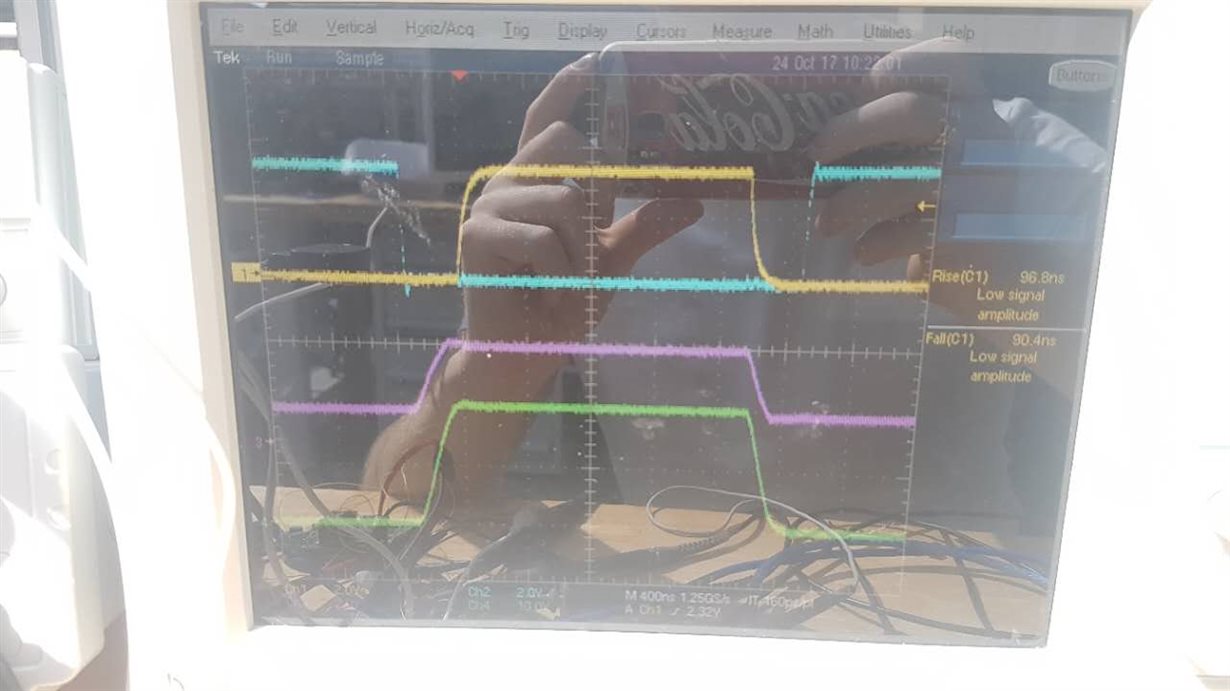

Input pwm is CMOS level, 500kHz , phase shift 180 degrees between Li and HI , 5 cycles of deadtime (at FSW).

The power pad is connected to 4 layers of ground plane. The boards stays around 34 degrees celcius. It is really the mosfet driver that heats up so much.

What can i do to solve this problem ? simply add some more cooling to it or slow down the switching ?

.