Other Parts Discussed in Thread: LM555

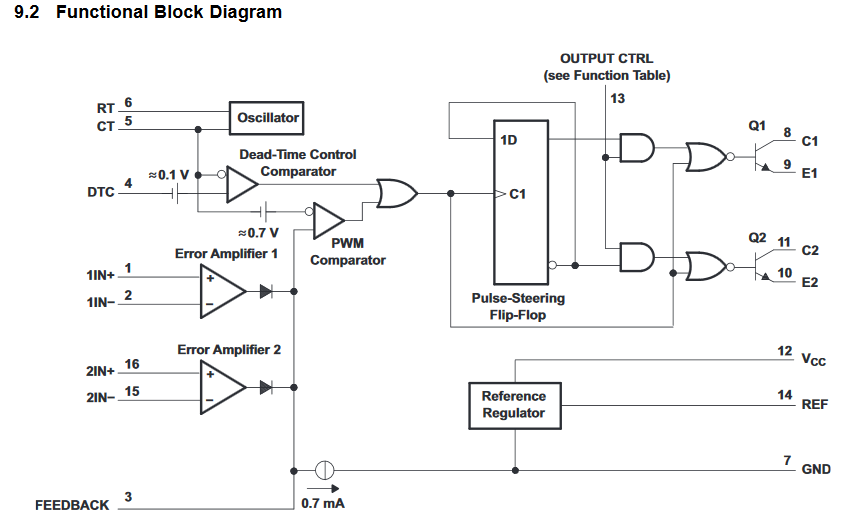

I know in the datasheet that it requires the IC to have CT and RT connected with equation 1/RC = frequency so I have 100pF and 500K Ohms connected to CT and RT respectively. I have DTC grounded and Emitter 2 grounded. VCC is connected to a 15 V source and GND is connected to GND. C2 is my output and output ctrl is connected to ground to enable single-ended mode. Are there other pins I need to connect or can I just leave them as open.

Again I am trying to set-up a 20 kHz frequency with a duty cycle of about 50%. I thought grounding the DTC will give me a 45% duty cycle according to the datasheet but I get about 5/10% on my scope. How do I vary the duty cycle and how do I get it to output correctly. I left 2 noninverting and inverting inputs as open as well as C1, E1, Ref, and Feedback. Any tips/ explanation on how to proceed?