Other Parts Discussed in Thread: CSD25402Q3A

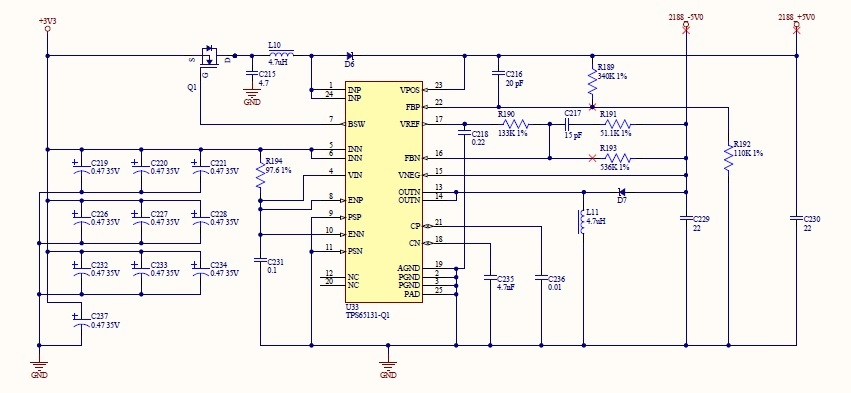

I am using the TI TPS65131-Q1 Buck/Boost Inverting supply. I ran through the TI WEBENCH to configure the circuit for 3.3V input and +/-5.0V output. I laid out my circuit exactly as the WeBench circuit. I even used the exact parts specified by WEBENCH. I have checked that all of the parts are in correctly. I just get nothing on either the Vpos or the Vneg. This is the first time I have used one of the buck/boost supplies. It is completely different than a standard switcher. I am having a bit of trouble understanding what I should be seeing at different nodes to be able to debug the circuit.

I attached a pdf of what I got from WEBENCH as well as my schematic.