Other Parts Discussed in Thread: BQ24650, BQ40Z50-R1, GPCRB, GPCCHEM

Hello team,

Please see below question from the customer:

We have a 12.8V 6400mAh 4s2p LiFePo4 battery application. The BQ34Z100-G1 is being used in a "system" configuration. So the gas gauge is on the mother board, not inside the battery pack.

The tracker electronics and motor are all powered by the battery; the battery is charged using the BQ24650 + the application is -30 to 65°C.

Our initial test involved an electronics box with a circuit board with the BQ34Z100-G1 and an insulated battery powering it. If the unit was soaked to -30 °C and then a 10 Amp load applied the battery would immediately report that the State of Charge (SOC) was 0%. The condition would be "stuck-at" until the load was disabled and the temperature elevated, usually above 25 °C.

We took a bare PCB and our battery into a thermal chamber and were able to reproduce similar results (see images attached below)

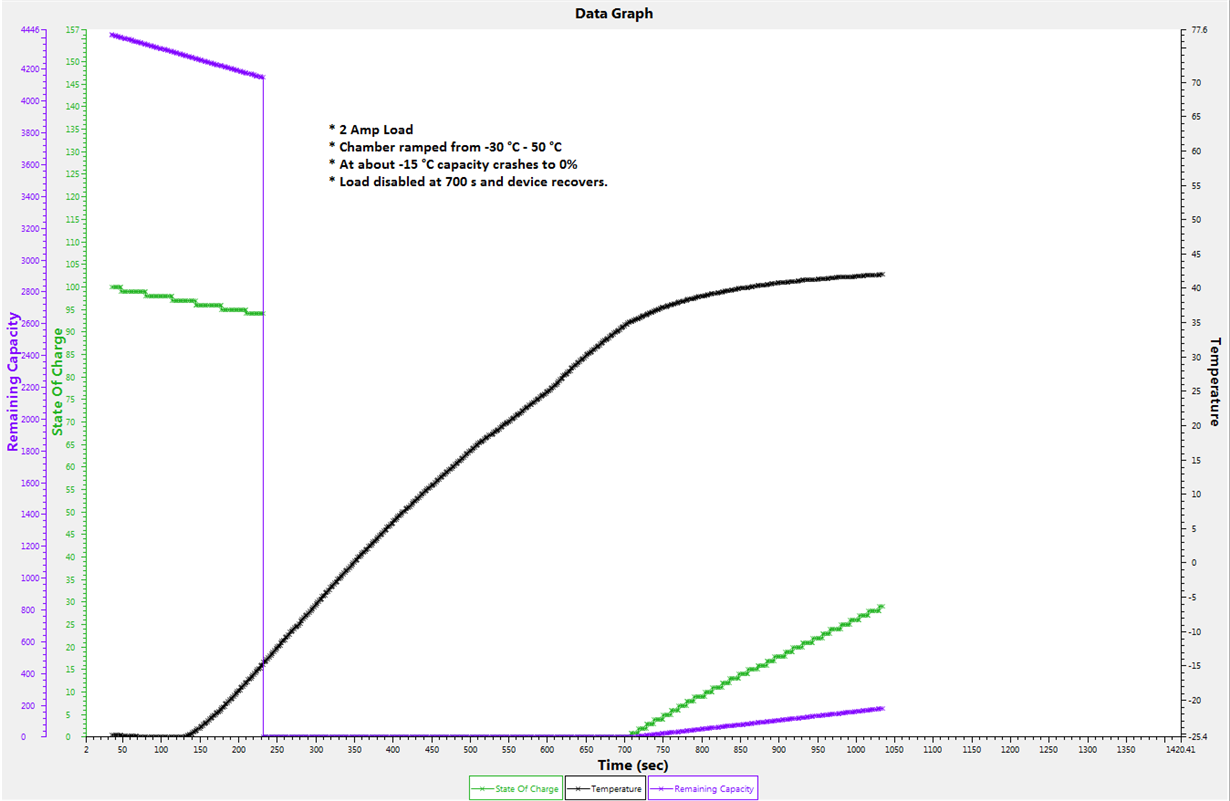

Below is a plot from TI Battery Management Studio. The battery and PCB were soaked to -30 °C and then a 2 Amp load was applied. Then the temperature was ramped towards 50 °C as fast as the chamber would allow. We conducted this test after finding that we could not reproduce the initial cold-start problem. The capacity readings did plummet though once the battery passed through -15 °C. This was repeated two more times with virtually identical results. The 0% stuck-at condition began recovering when the load was removed and after the temperature was elevated significantly

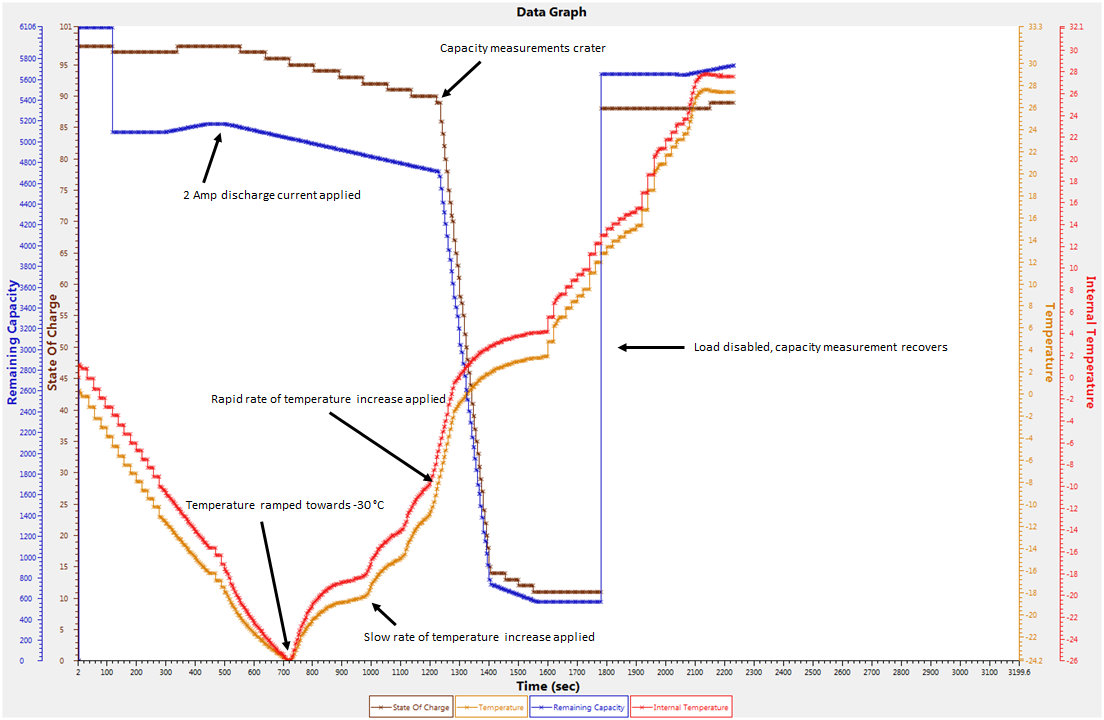

We attempted changing various IC settings such as turning off smoothing to no avail. Then on a hunch I tried adjusting the temperature at a finer level than before (depicted below). Instead of the chamber elevating rapidly I adjusted it in small steps. The battery reported correct behavior well past -15 °C. At this point I decided to again allow the chamber to rapidly elevate the temperature and the same issue arose around 0 °C. Recovery followed a similar trend where once the temperature was sufficiently elevated and the load removed the readings would again report reasonably.

For my part I suspect that the common thread here is rate of temperature increase. I could not understand why our unit-based (enclosed) battery behaved differently from these follow-on tests in regards to the initial cold start. Then I realized that I could measure a large positive temperature deflection in the battery pack when large load currents were applied at cold. Even with an uninsulated battery pack there was appreciable battery self-heating in our latter chamber tests. The enclosed unit is well insulated and I'm presuming that the self-heating would be more dramatic. If a certain temperature slope is what's throwing off the IC then it might stand to reason that I achieved that in our first tests with an enclosed battery. That's speculation on my part as the common thread appears to be rate of temperature increase and not any of the particular settings within the IC.