Good Afternoon,

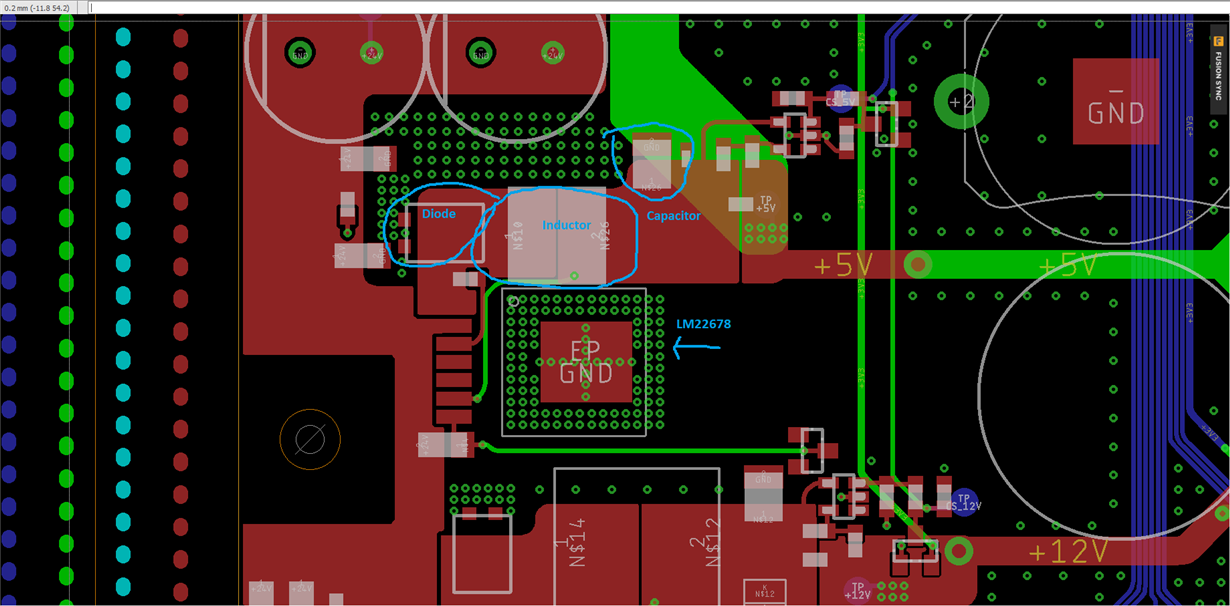

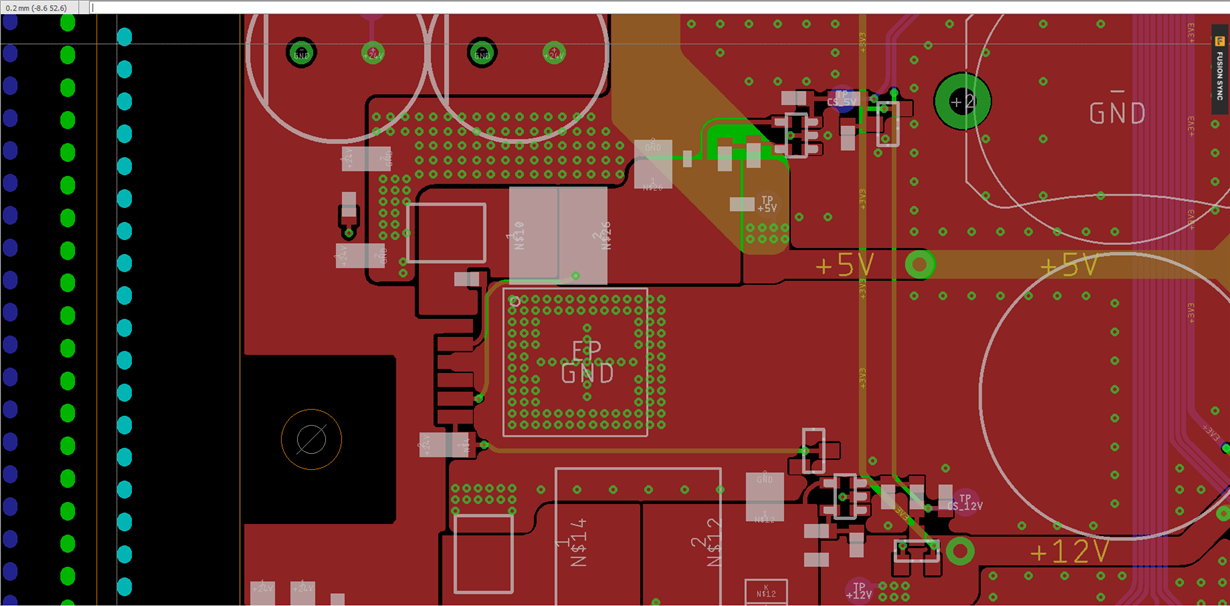

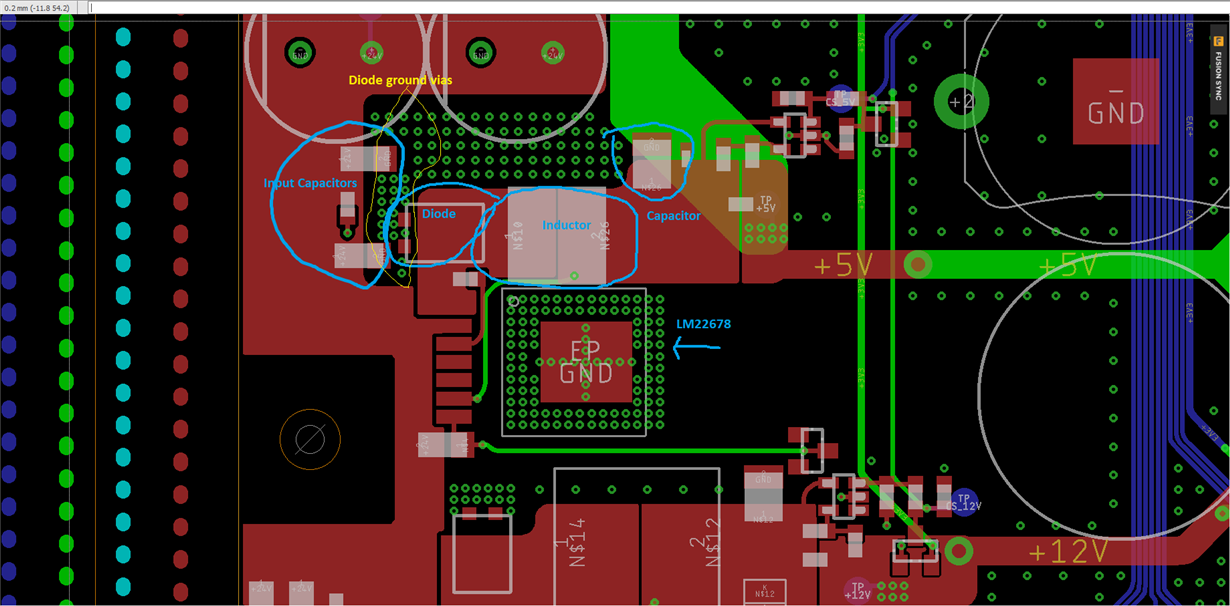

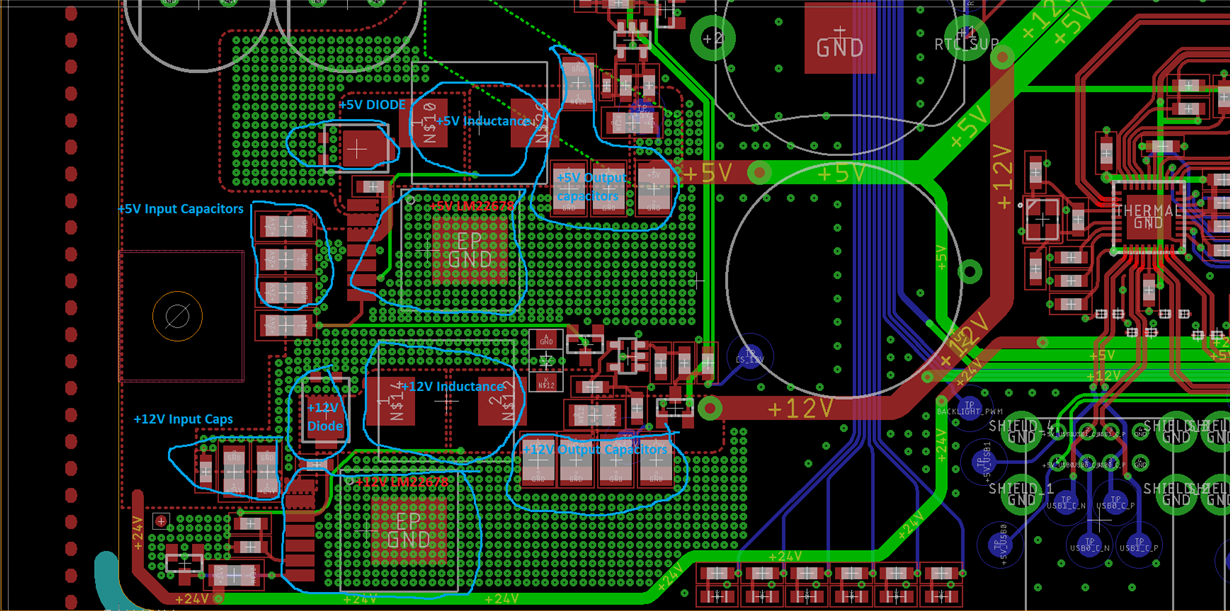

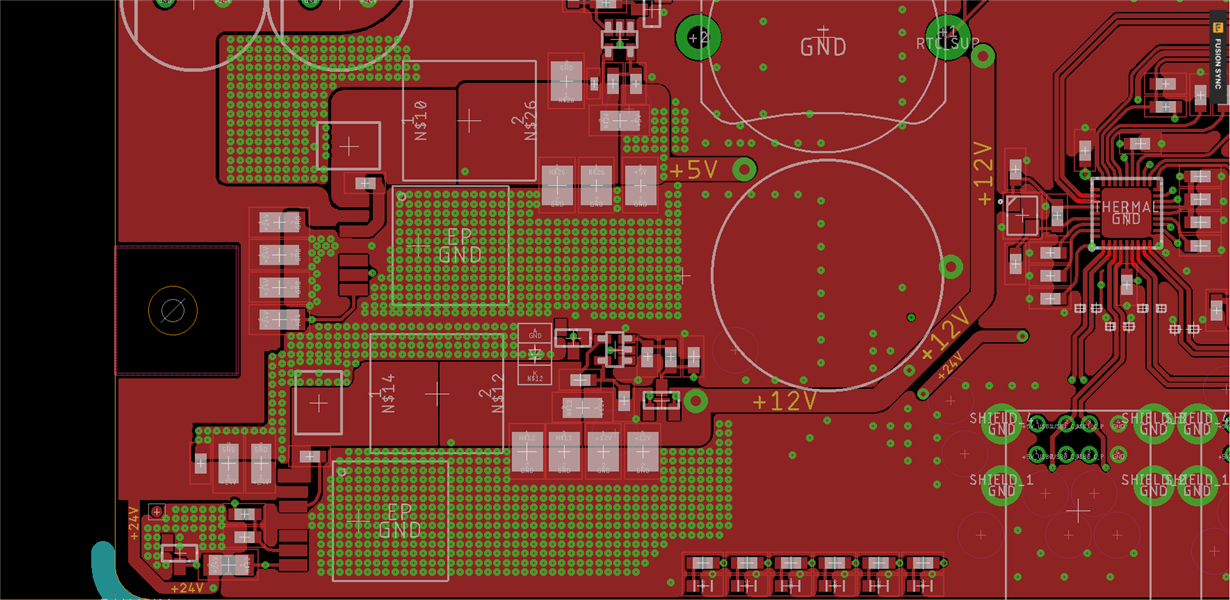

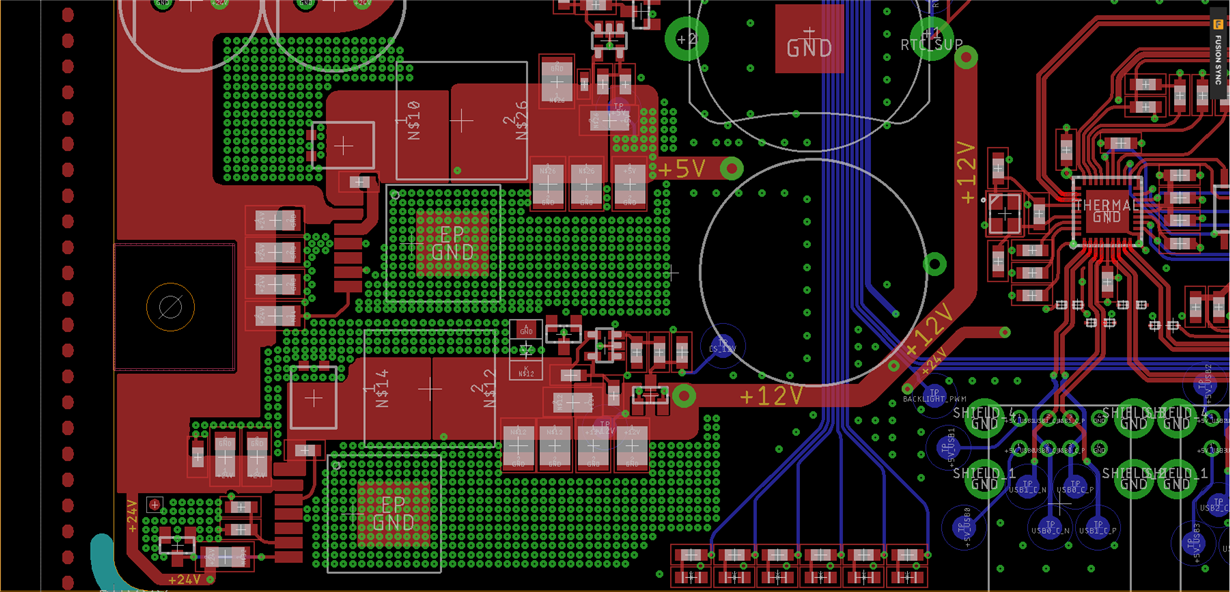

I am developing a board in which I will use 2 LM22678, one to provide +12V, the other one for +5V. You can find the schemes below, generated with Webench and implemented with Eagle CAD.

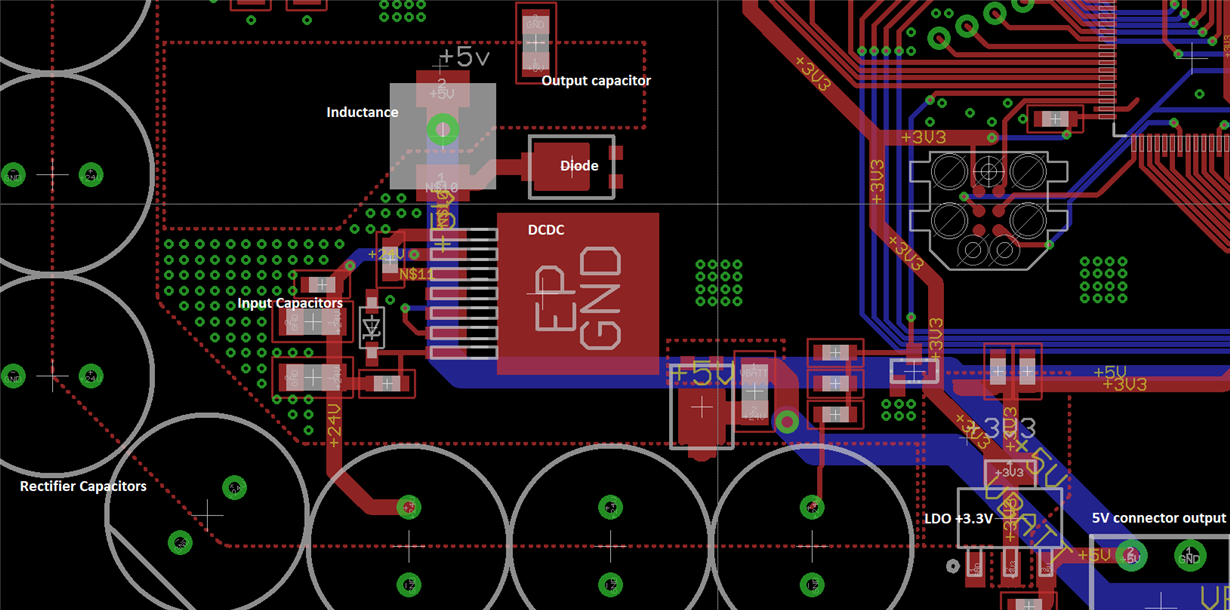

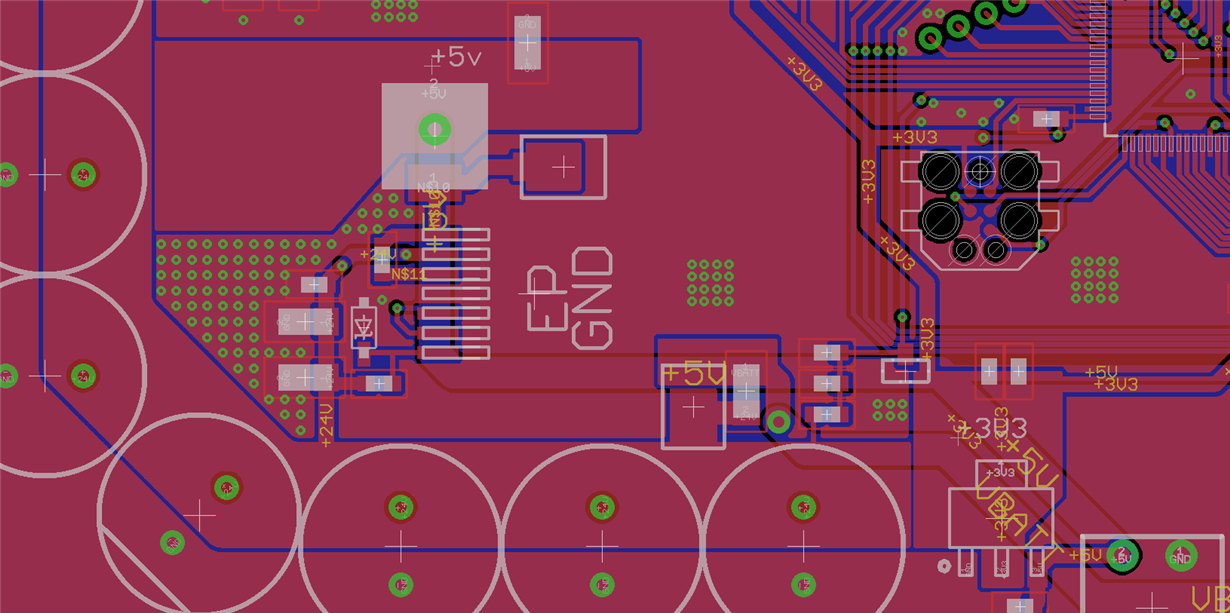

- The input of the circuit is a 24VAC rectified and filtered through 8 x 680uF Electrolytic Capacitors, obtaining +35V. For the +5V DCDC, when the 35VDC switches off, there is a 10V battery pack (NI-MH) used to provide a soft-shutdown.

- The diode in both the DCDC is a MBR10200UPS-TP.

- The inductance is: ASPI-0630LR-5R6M-T15. In the 12V DCDC there is a series of 2 of these.

- Except for the filter, the other capacitors are ceramics.

- The enable input of the 5V DCDC is fixed high with a resistor and Zener diode. The 12V can be switched off by a microcontroller.

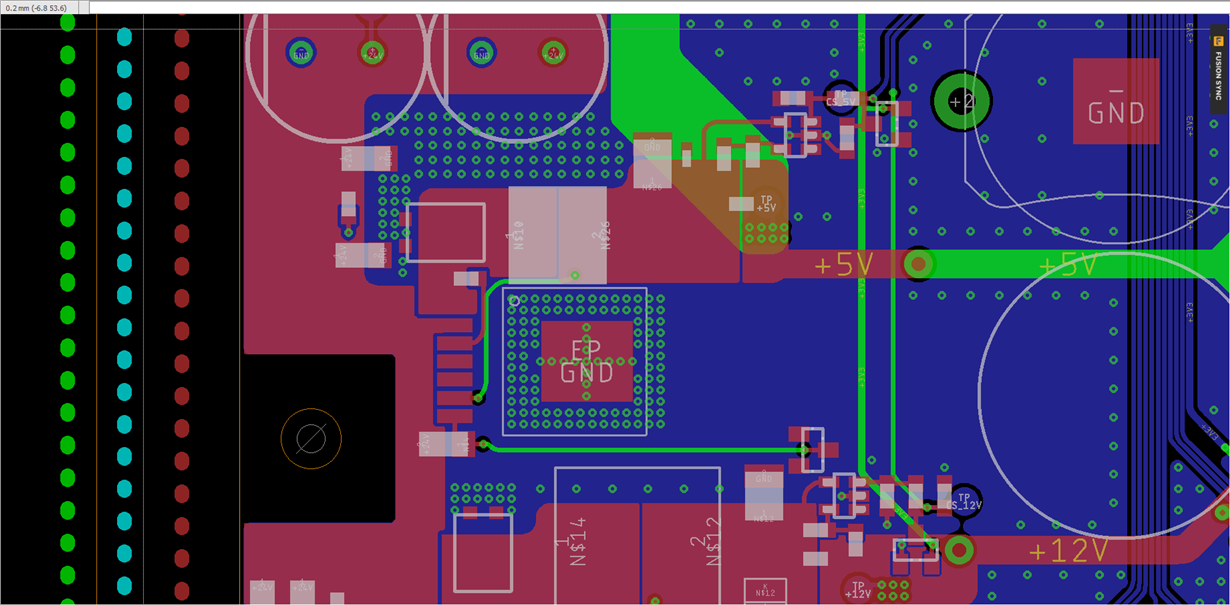

The layout of the DCDC that generates the +5V is attached below. The load of the 5V is a Display (0.8A), a Raspberry PI3 (0.7A) and an LDO (0.3A) that supplies a microcontroller (overall 1.8A).

We have 7 prototypes that are in use since May 2017. The DCDC of the 12V never had failures, it works fine. The DCDC that generates the +5V, sometimes, sporadically, has failures. When it fails, also the LDO (TLV1117LV33DCYR) and the microcontroller fails.

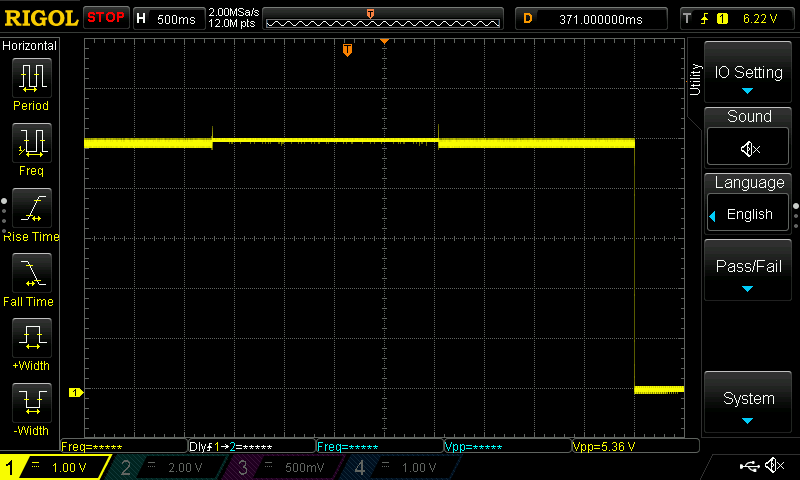

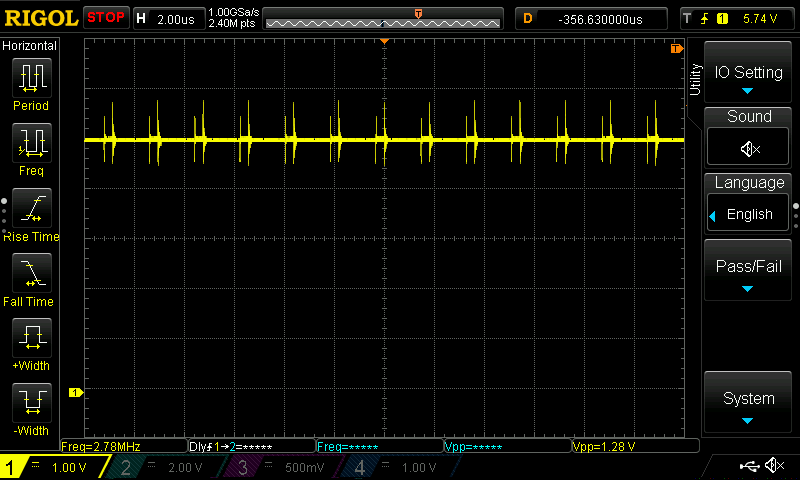

The first hypothesis was that the problem was thermal, the DCDC in a box could reach 100°C (212°F). Stressing it, connecting a higher load (1.8A-2.0A, so overall 2.8-3A) to the display supply connector, the temperature grows to 130°C (266°F), and the DCDC goes in protection because of overtemperature. But seems not having any failures. I tried so to disconnect and reconnect this load to the board; the result was that the LM22678 got inflamed (usually, when there is the failure, the board just switches off, but I have never seen fire). So now my hypothesis is that changing the load can creates the failures. I think also the display can be considered a not constant load, and causing, after some time, the failure. The “high load” was connected and disconnected other times before the crash, so it does not happen immediately.

Do you have any idea of which can be the real cause of the failure? Do you have some tests to suggest?

Below there are photos of 3 failured board.

I can send you the components, 3xLM22678 and 2xTLV1117LV33DCYR in order to do a failure analysis. Is it possible?

Kind Regards