Other Parts Discussed in Thread: TPS54140

Hi Jeff,

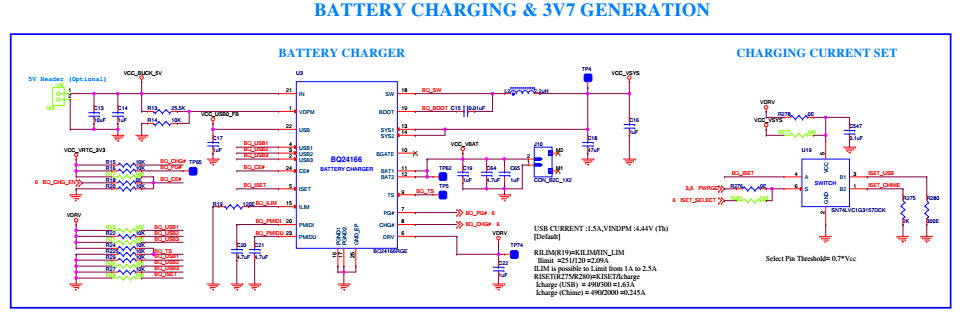

In our design we connect the TS pin with an equal sized resistor divider from DRV to TS to GND. So I would like to know how the TS pin will be functioning in this combination of resistors. Will there be any role of Vwarm and Vcold in this setup. Is there any Temperature control being done in the charger if the Battery does not have a NTC pin.

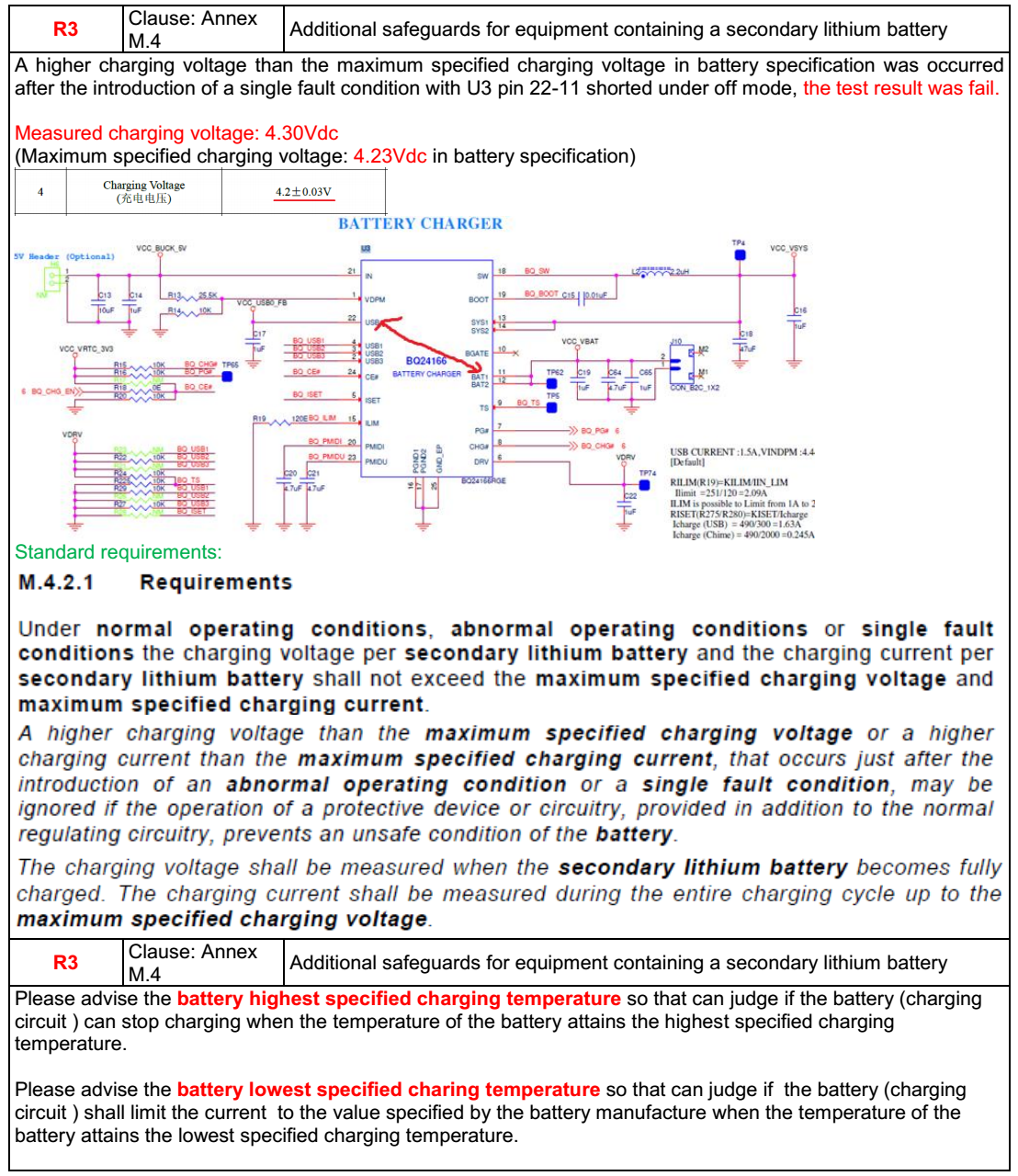

I have one more doubt. We had given our device for certification. We got a feedback from them as mentioned in the attached image. Can you please comment on this. Is there any chance of raising the Vbat voltage to 4.3V as they mentioned?

We are facing problem in certification due to this. We expect your advise and support. Expecting your reply soon.