Other Parts Discussed in Thread: BQ34110EVM-796, BQ34110

Hi,

I'm working on development with bq34110evm-796, and I specifically need help with configuration of the gauge to obtain accurate gauging with my battery pack. My questions are:

1) I watched training.ti.com/gauge-programming-fundamentals , where it is said that each Gauge has a minimum set of parameters that need to be changed to account for a particular battery. The datasheet and TRM are not clear about which these parameters are. So I changed the following ones based on battery datasheet and charger datasheet:

Addres Name Value

0x408A Design Capacity mAh 1700 mAh

0x40C0 Learned Full Charge Capacity 1700 mAh

0x425A Fixed EDV0 3000 mV

0x4114 Charge Voltage T1T2 4000 mV (*)

0x4116 Charge Voltage T2T3 4000 mV (*)

0x4118 Charge Voltage T3T4 4000 mV (*)

0x4120 Taper Voltage 100 mA

0x411C Taper Current 45 mA

0x411E Minimum Taper Capacity 0 mAh

(*) The charger I'm using LTC4064 charges to 4V.

Am I missing any necessary parameter?

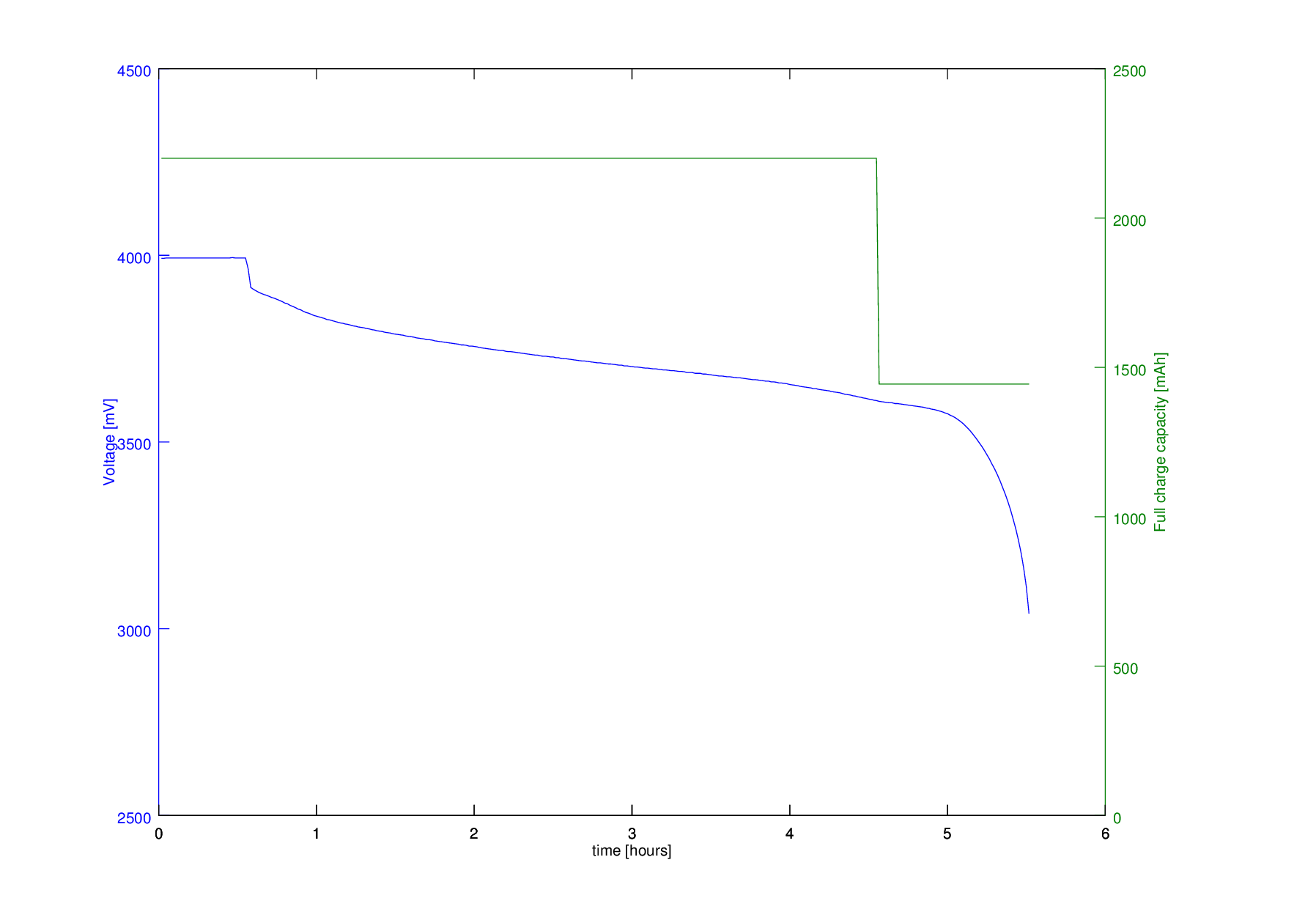

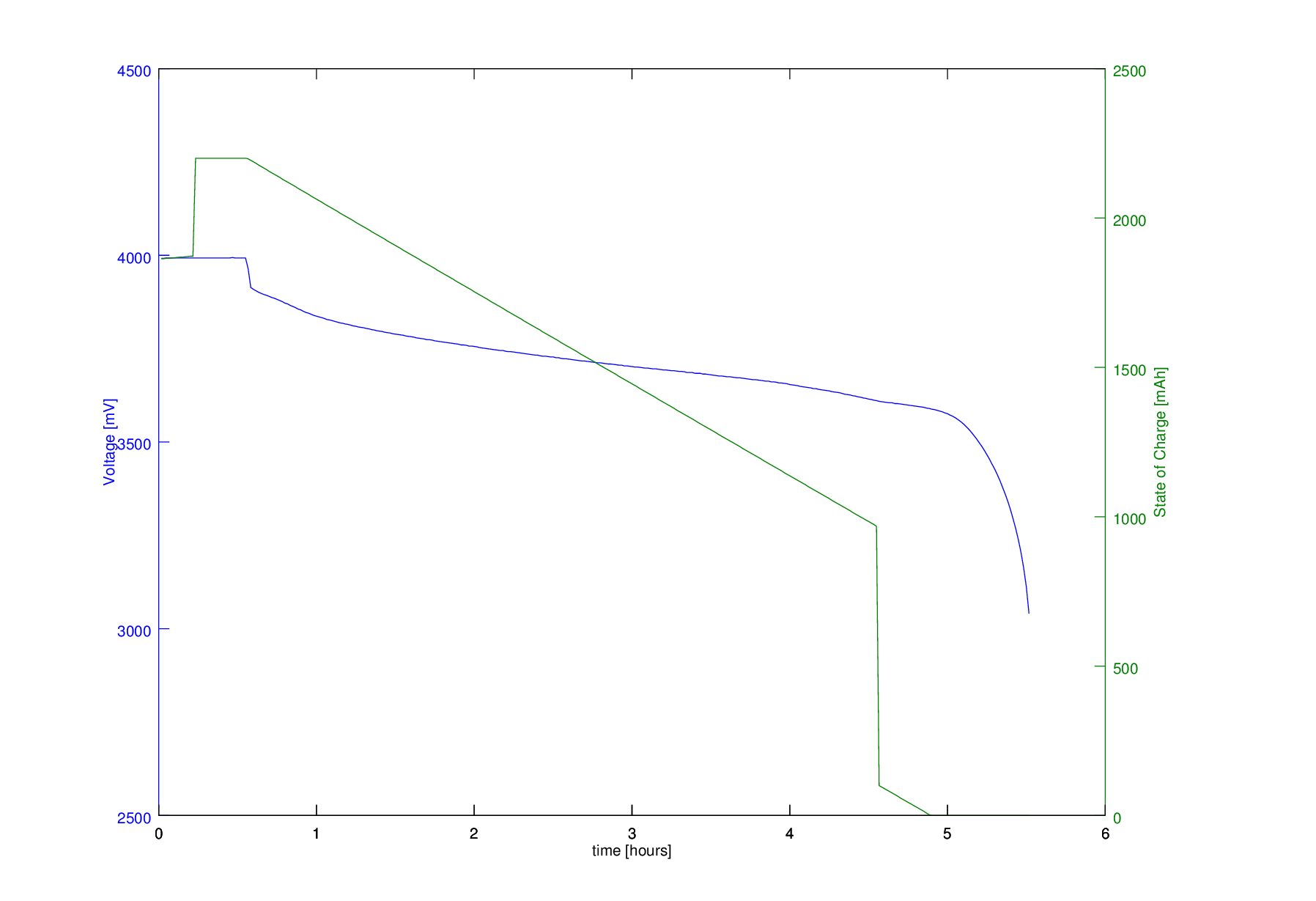

2) After setting the parameters above I performed a full discharge (qualified discharge) and logged the data. I attach the graphs. I found that Full Charge Capacity (FCC) was 2200mAh from the begining, and around EDV2 it adjusted down to 1444 mAh. I know the BQ34110 updates the battery capacity on every qualified discharge, so I expected that writing 1700 mAh into Learned Full Charge Capacity would set the initial learning state to my nominal capacity of 1700 mAh, which it didn't.

In powerpoint "Common issues and solutions.ppt" page 13, I understand that after a learning cycle, some register in flash memory contains this learned condition, and may be then part of the Golden Image to be programmed to each GG and work as the initial condition.

Which is the parameter (Address / Name) that I have to change so that the Full Charge Capacity starts with 1700 mAh instead of the default 2200 mAh even in the first qualified discharge?

3) In production, batteries are usually stored in stock with around 50% charge. So the first time that the product is turned on, the state of charge will be around 1700mAh / 2 = 850 mAh. The first discharge shouldn't be a qualified discharge, because RC < FCC – Near Full, but in order for the BQ34110 to make this judgement I should be able to store FCC = 1700 mAh, and SOC = 850 mAh, as an initial condition.

How can I set this initial condition?

4) What should the manufacturer and/or the client perform as a first turn on of the product? Are any of these expected to perform a full discharge or charge cycle?

Thanks,

Gustavo