Other Parts Discussed in Thread: BQSTUDIO, , EV2400, GPCCEDV

I'm working with a BQ34110 to monitor a 3000mAh 25.4v LiFePO4 battery pack. The pack contains 16 cells total. They are configured as 8 series sets of 2 parallel cells, so as far as the gauge is concerned, I am using 8 series cells. I am using bqStudio w/ a EV2400 to communicate.

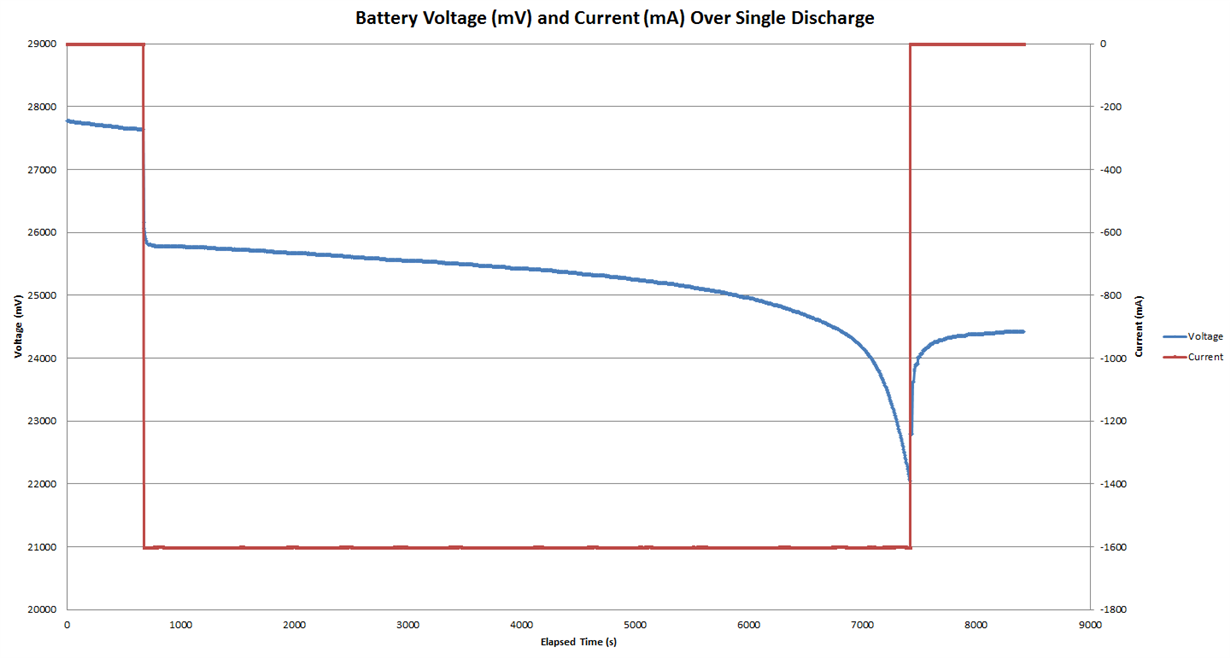

The problem I'm having is configuring the gauge to correctly monitor the remaining capacity and Relative State of Charge. I have set up the Voltage Divider parameter, calibrated the voltage and current, set the number of series cells, and I am getting accurate readings for both Current and Voltage from the battery pack. After draining the battery pack, I then charge the pack using a supplied charger (We will not be using the charging functionality of the bq34110). The bq34110 appears to properly measure charging current and increases the Remaining Capacity up to the 3000mAh. I then began to discharge, and to my surprise, the remaining capacity suddenly shoots down to <10% and the Full Charge Capacity register now reads 2744mAh. This is odd, as I had thought this register could not change unless a "Qualified" discharge was detected, and the VDQ bit that detects this state never went high during the discharge.

So at the moment I'm not quite sure what to do from here. Have I missed a step in the process of configuring the bq34100? Is configuring the CEDV profile mandatory to use the device in this way? If that's the case, is there an up to date reference on how to acquire these parameters and take these required logs? Are all six different logs required? (also FYI, the CEDV Technical Reference link in the GPCPackager tab is dead) What portions of the device do I actually need to configure to simply have access to Current, Voltage, and Remaining Capacity?

Thanks in advance for any assistance