Hello,

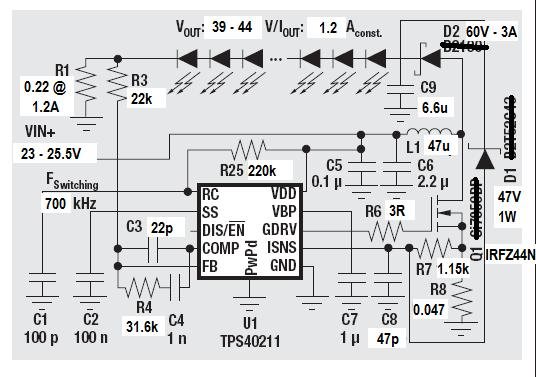

I have designed a boost led driver which drives 12 power LEDs in series with 1.2A constant current. LED string and power supply voltages varies 39 to 44V and 23 - 26V respectively. I made the calculations for %20 p-p ripple with 700kHz switching frequency from the information given in product datasheet. I attached the schematic to post.

When i powered the system LEDs started flashing. I first thought soft start cap should be bigger value than i put a 1uF but this only changed flashing speed. This meant that driver was sensing an overcurrent state so i lowered Isense resistor but didn't work. Than i tried to decrease LED current and flashing stopped at 350mA. Since than i tried a few things too but couldn't stop the flashing above 350mA current.

I hope i could have explained the situation well. Waiting for possible reasons and solutions for the problem. Thanks in advance.