Other Parts Discussed in Thread: UCC27517A, UCC27517,

Hi

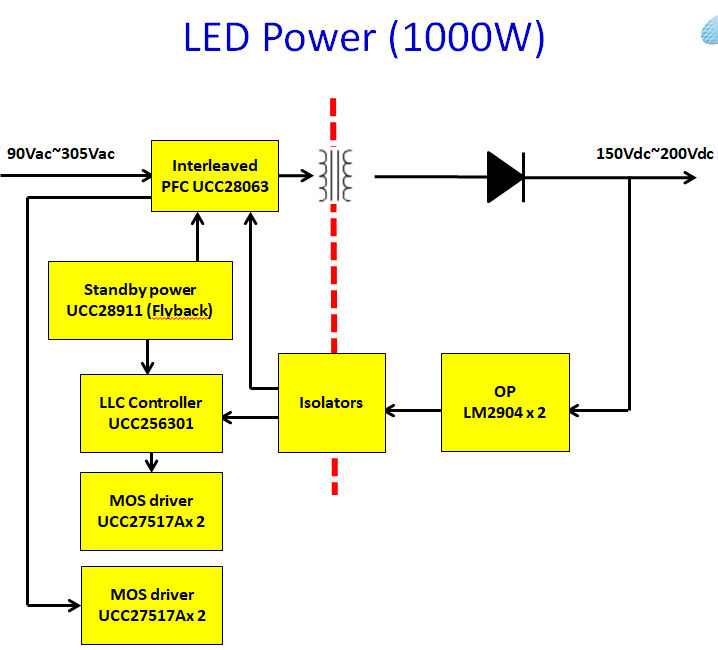

Currently we have a 1000W project is based on the PFC+LLC architecture.

There are two questions. Can you help us?

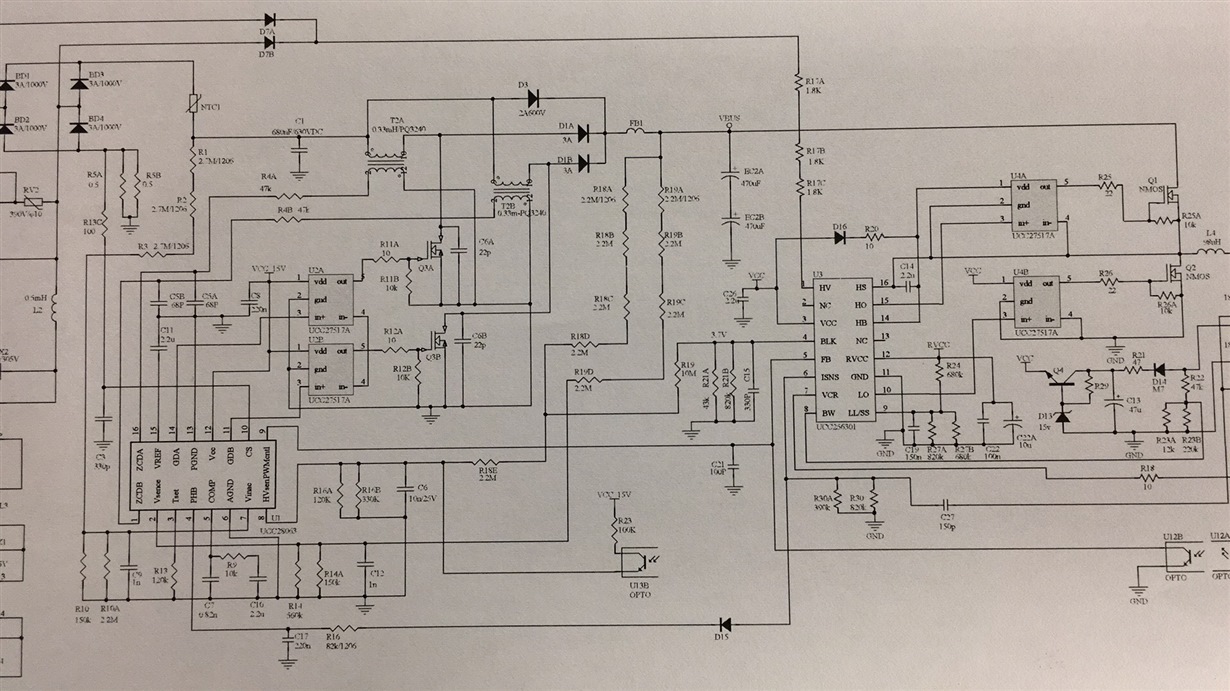

1. Whether UCC27517A VDD is connected correctly or not? (such as an attachment)

2. If we want to change to LCC architecture. Whether or not there is a LCC tool can help us design the circuit.

What is the difference between the sampling circuit of LCC and LLC and how to determine the LCC sampling capacitance parameters?

Thank you.