Other Parts Discussed in Thread: BQSTUDIO, BQ76920

Hardware Configuration-

Refering to the Datasheet of the BQ78350-R1:

Q0: KEYIN: A low level indicates application key-switch is inactive on position. A high level causes the DSG protection FET to open. If this pin is not used, then it should be tied to VSS.

Can the system only turn the DSG-FET on and off, only I use the function of KEYIN?

So when I connect the KEYIN-Pin to Ground, the DSG-Fet will always be in on-state?

Q0b: If the answer to question 0 is yes: Is there also a pin to control the state of the CHG-Fet to turn of or on?

Refering to the Technical Refernce of the BQ78350-R1:

Q1: !PRES: The bq78350-R1 has the capability to detect the presence of a system and/or a charger through the stateof the PRES pin. This can be used to disable the battery output when the bq78350-R1 detects the battery has been removed from the system or charger.

My question refers to the second sentence: When the battery has been removed, the battery ouput is disabled eitherway. Can you get in more detail, what do you mean?

What kind of hardware should I connect to the PRES-Pin, if I want to use the fuction?

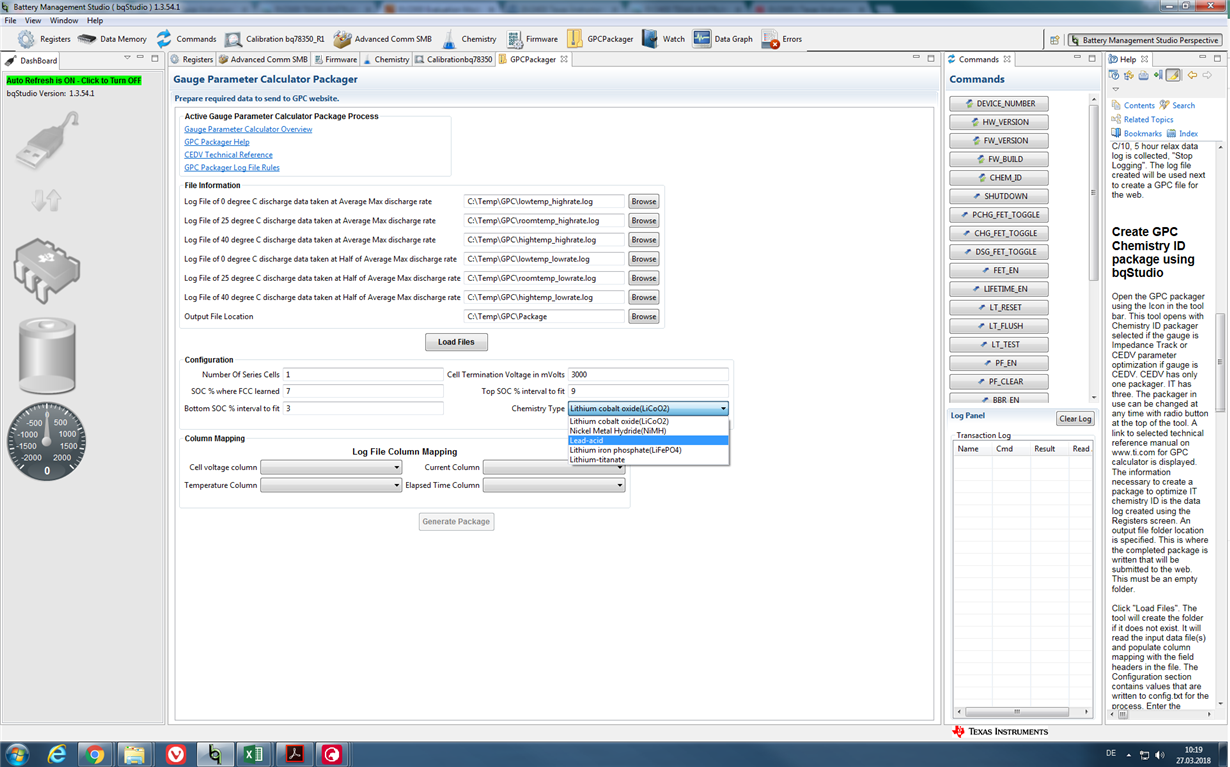

Q3: If I want to choose the right Battery-Chemistry-ID, is it said that I have to log the discharge behavior of the battery by 0 °C. 25 °C, and 40 °C with average max discharge and half of average max discharge

How do you simulate these temperatures by a discharge process?

What do you mean with max discharge? Is the max discharge refering to the current, during discharge?

Thanks for help

VAUX,PRES

Log-Files- Temperature: 0 °C, 25 °C, 40 °C