Hi

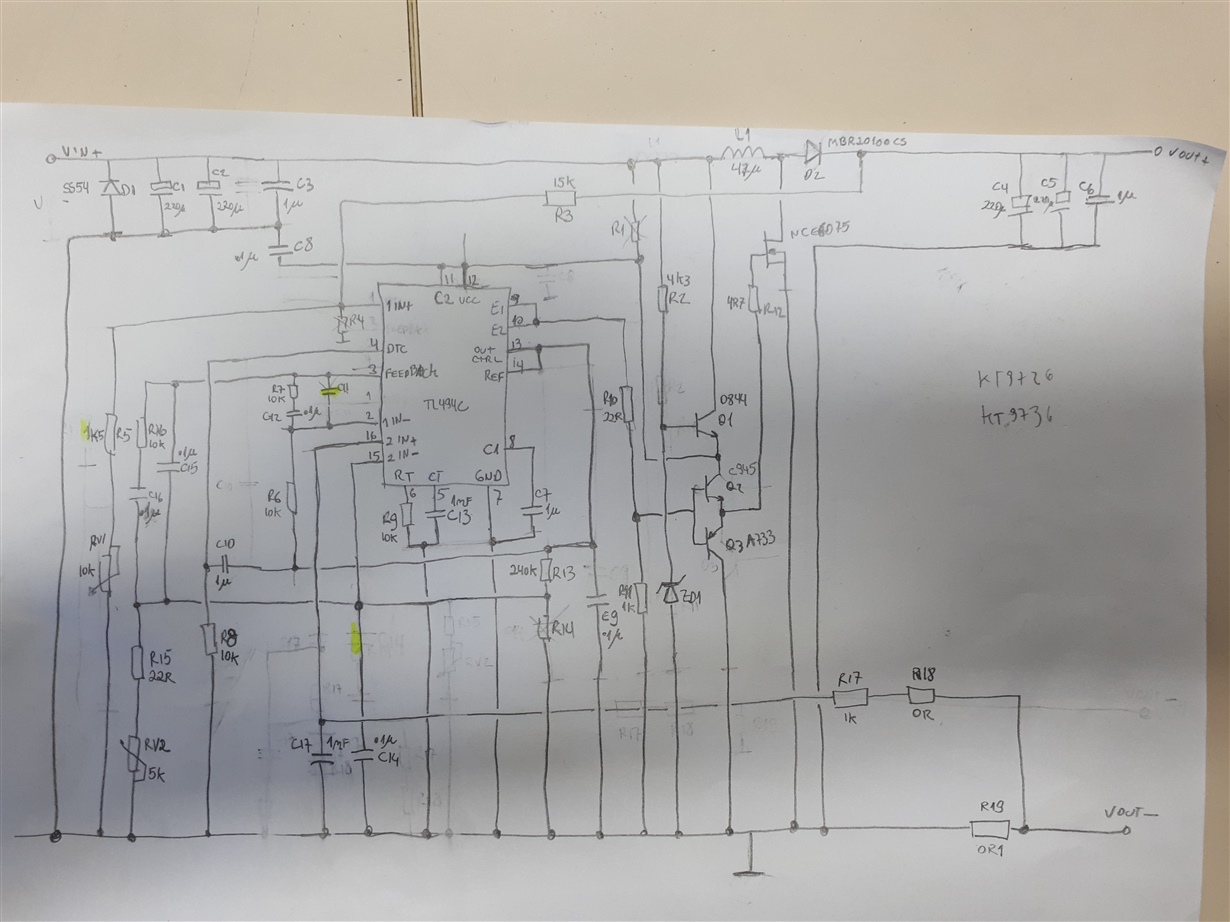

I am using a typical Chinese DC-DC converter (constant current) 250W assembled on a metal core laminate to drive some string leds.

The configuration is : input : 12 VDC - 2,5A - Output 25V- 1,2A - total 30W. I firstly used 10 samples to submit 2 month test and they worked well.

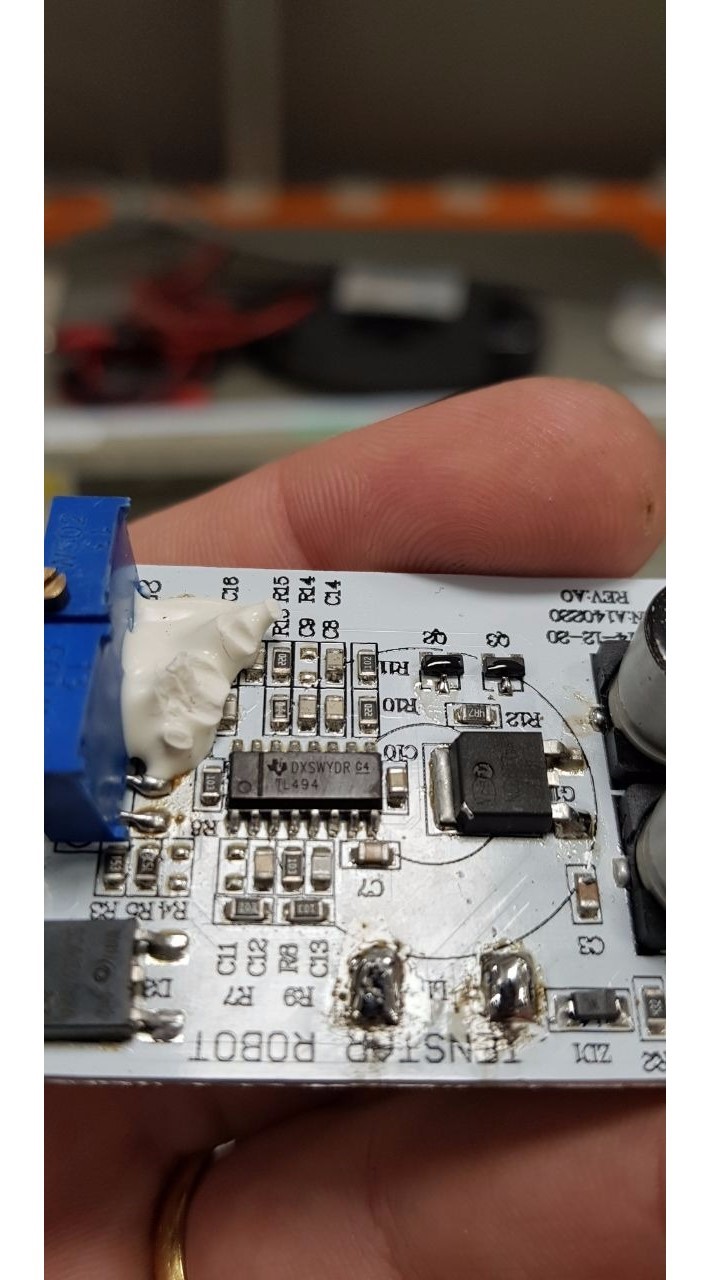

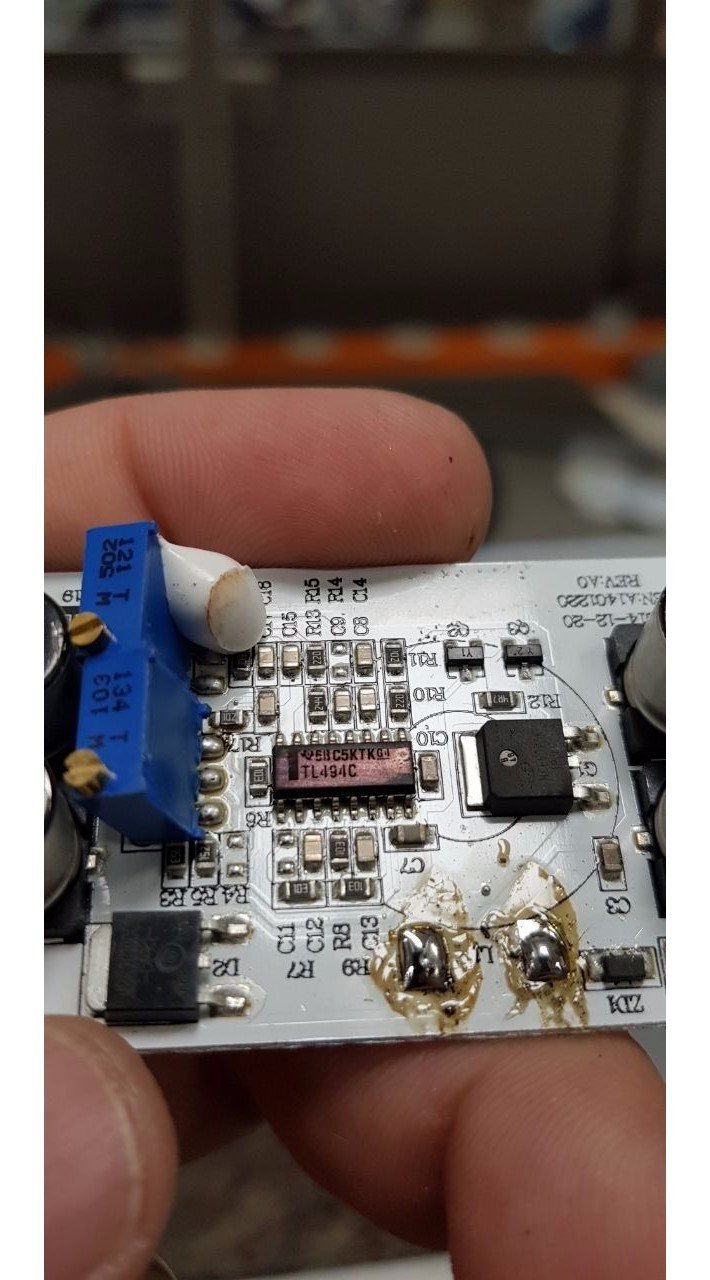

Now I have a customer order of 1000 pcs and ordered the dc-dc converters direct from china. The module is based on TL 494 with 2 tripots for output current and voltage adjust.

When I started testing the product, I noticed all the batch is producing a peak of current when I turn on the PS. Such peak of current , when adjusted for 12V input, occurs for around 0,5 seconds during startupand the system returns to the voltage and current previously adjusted. If i reduce the input voltage to less than 11VDC, the peak occurs but the system does not return to adjusted values, As result, the pcb increses the temperature and will fattaly burn the module.

I replaced the TL 494 bey new ones and notices the modules became muc,much more stable, but I still notice a little peak of current in voltages lower than 12V. In this case , it is only a start up peak and the circuit starts working. I claerly noticed there is something wrong with the original TL494 that came with the batch. Has anyone experienced such problem already? Is it the TL494 the responsible for such peak , or could be a deffective capacitor of the typical application?