Tool/software: WEBENCH® Design Tools

Hello,

I am designing power supply circuit using TPS63070.

My application requirements are as follows

Vin : 6V to 8.4 V

Vout : 8 V

Load current : 800 milli amps

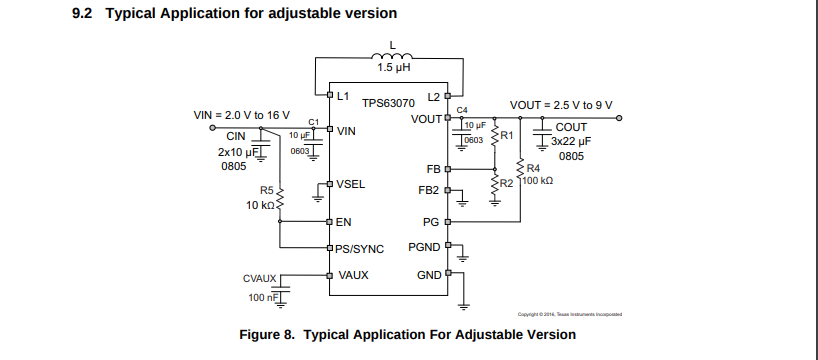

As shown in the below figure , Application circuit of datasheet is suggesting 10uF (0603) capacitor, two 10 uF (0805) capacitors at input and 10uF capacitor(0603) , three 22 uF (0805) capacitors at output.

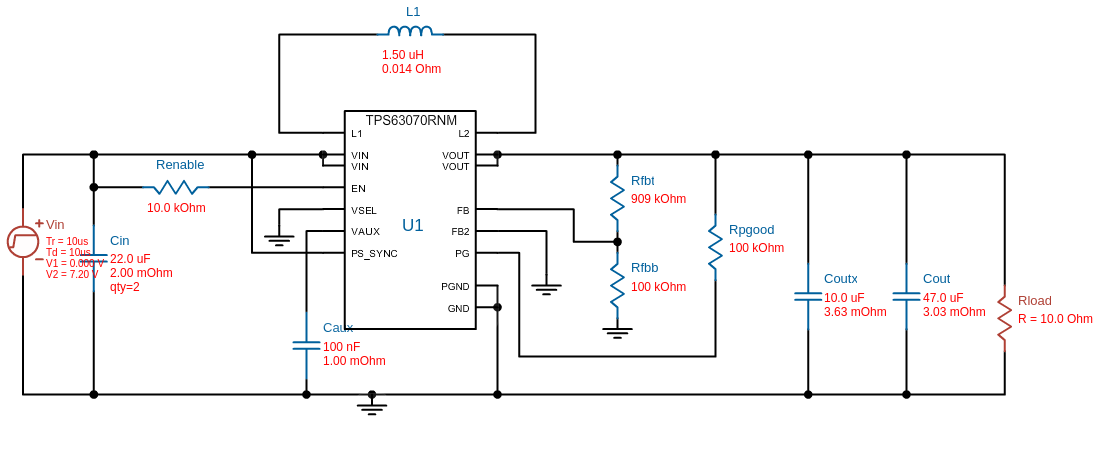

In contrast as shown in below image, TI webench simulation result is suggesting two 22 uF (1210) capacitors at input and 10uF (0603), 47 uF (1210) capacitor at output.

Please suggest pros and cons of both designs and also suggest the suitable design for my application as mentioned above.