Hello:

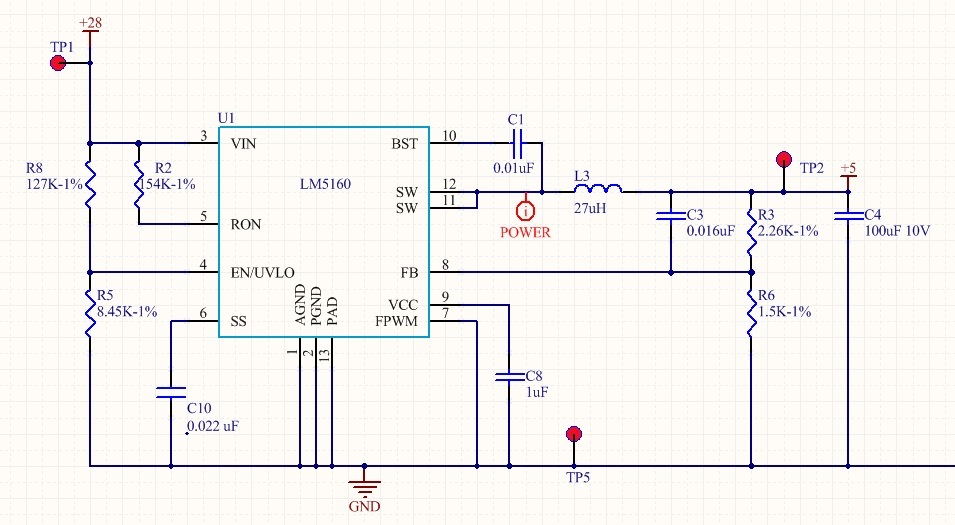

We used the Webbench design tool to make a design for the LM5160. It should take +28v and convert it to +5v

Upon first power up, with no load, we have destroyed all five of boards with the LM5160. The part turned on, regulated to +5v for about 4-6 seconds, and then the input current spiked to about 0.8amps at +28v and the part smoked. I've checked the reference design, web-bench, all the parts on our board, the pinouts, the layout, and rebuilt the design in the TI-TINA tool. Everything says the design should work, yet the part is failing immediately.

What could be causing this? Please help