Other Parts Discussed in Thread: BQSTUDIO

Tool/software: WEBENCH® Design Tools

Hello everyone,

I am testing battery of type : Lead acid , 12v ,1.3 Ah capacity.

Iam able to get voltage of 12v in bqstudio. To get the remaining parameters , i started performing learning cycle.

i updated the chem id to 0802, design capacity :1300 Mah , design energy :15600

Enable IT

2. Send Reset command (0x0041)

3. Charge the pack to charge termination.

4. Rest until the OCVTAKEN flag sets

5. C/7 Discharge to the termination voltage

6. Rest until the OCVTAKEN flag sets. At this point, QMax should update and the Update Status should increment to 0x05

7. Charge the pack to charge termination

8. Rest until OCVTAKEN flag sets

9. C/7 Discharge to the termination voltage

10. Rest until the OCVTAKEN flag sets. At this point, the Ra table should update and Update Status should increment to 0x06

As per declared in previous posts,

i followed above posts , i had charged the battery and after few hours, ocvtaken flag has been set.

next step i discharged the battery by considering: C/7 parameter -->1.3Ah / 7=0.18 A ,-->R=12/0.18=66ohm, i had taken 66ohm resistor , started discharging the battery

after 5 hours rest no change in learned status and ocvttaken flag also not set.

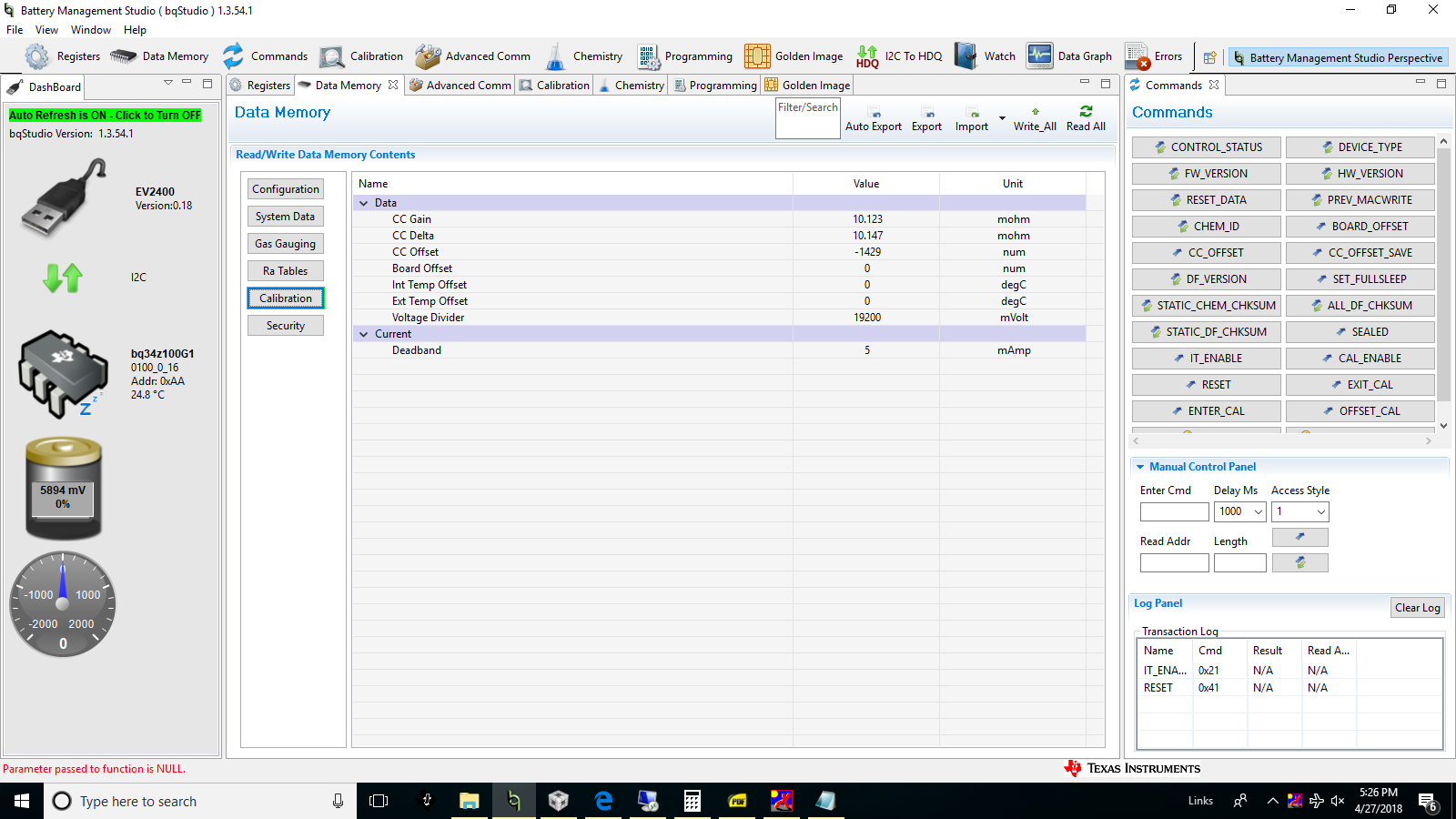

I am attaching the log . so kindly help me . my settings in bqstudio are

I am attaching the log of discharging the battery