Hi all,

I need to design a DCDC converter with the following specs:

-Vin=6 to 12V nominal (to withstand automotive cold crank)

-Iout = 10A

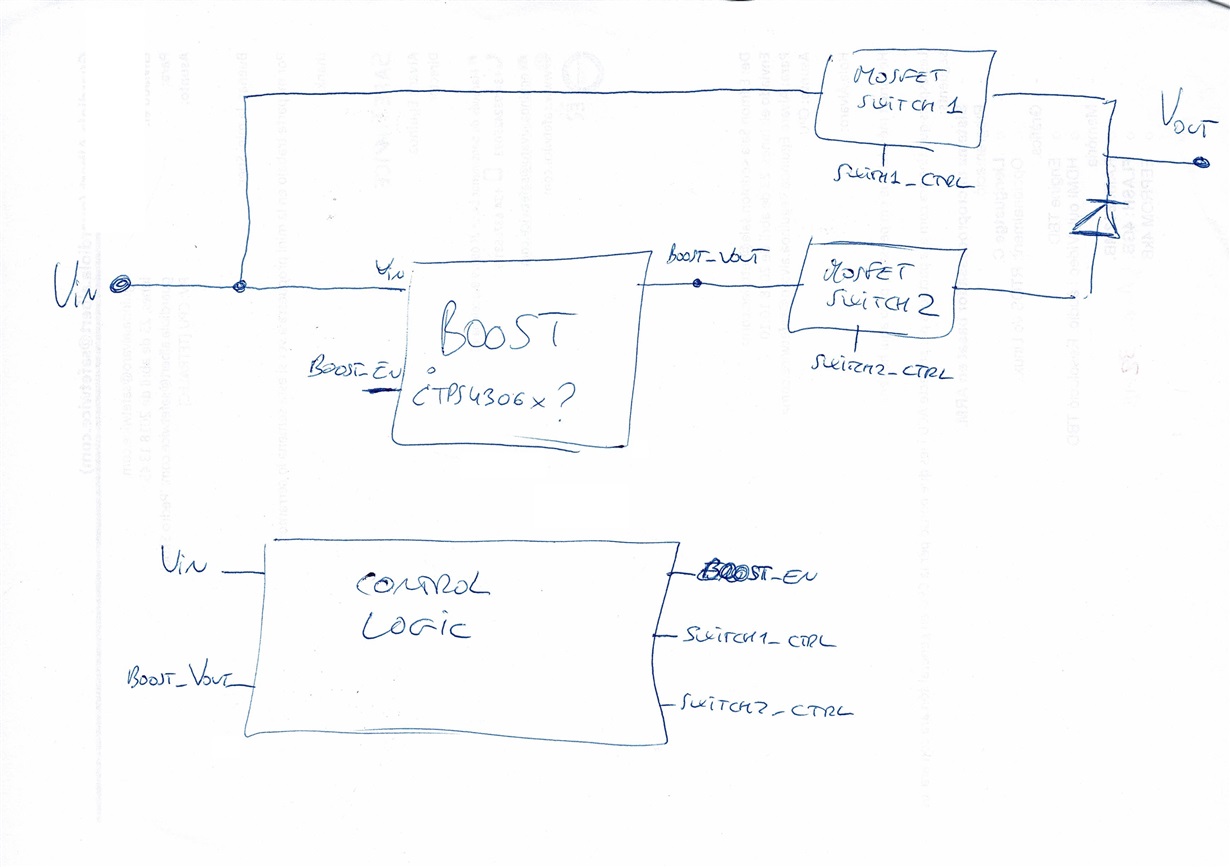

-Here's the tricky part: If Vin<11.7V then FAN48623 Vout=13.2V; if Vin>11.7V then Vout=Vin).

So I cannot use straightforward the bypass function included in LM5122, since my Vin threshold to enter bypass is not the same as the Vout target value. Therefore, I would need a controller that includes a "forced-bypasss mode" (let's say, with a dedictaed pin, such as Fairchild's FAN48623). Could you recommend some Texas controller that would match these specifications? If not, any app note that comments on this peculiar scenario would also help.

Best regards, thanks indeed