Other Parts Discussed in Thread: BQ34Z100-G1, , BQ34Z100, BQ40Z50, BQ40Z50-R2

Hello,

I am trying to evaluate the BQ34z100EVM (BQ34z100-G1) with a 12.8V LiFePO4 pack (3300 mAh) made by aaportable (found a CHEMID which appeared to match the pack model and parameters). Link:

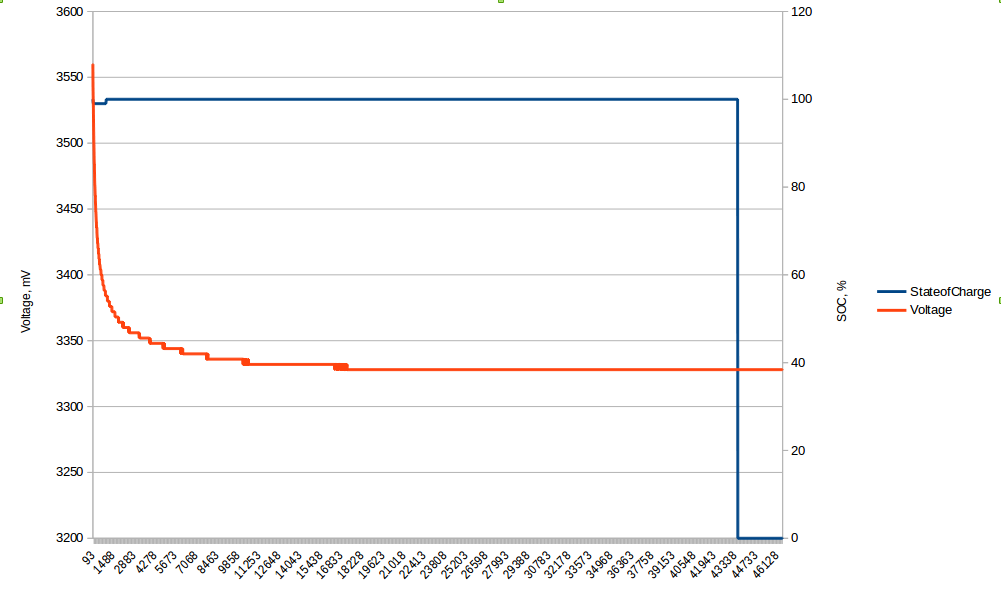

I started by discharging to the termination voltage. The protection circuitry appeared to cut off between 9~9.5V, so I discharged down to 10V pack voltage at ~0.2C (2500 mV per cell) to leave some margin. Following this, I sent the IT_ENABLE command and waited for OCVTAKEN=1. The charger used is a bq24773EVM, and the charger is shut off by a MSP430 which shuts off the charger as soon as the FC bit transitions to 1. I logged the results of the charge at ~0.2C and attempt at relax in "20180703-first-chg.csv" (in the attached zip). Relevant fields from the BQ34z100-G1 in this file are - Flags (hex), CtrlSt (Control Status in hex), Vactual_mV (Voltage), Iactual_mA (Current)

The pack was in the FC=1 state for a couple of days, and update status would not transition to 0x05. It appears to have timed out, as SOC was eventually reset to 0.

I have been looking through available documentation and forum posts, and cannot determine what is wrong with the configuration or charge profile.

I have included logs of RAM and Flash before the charge (20180703b4chg) and after charge (20180703afterchg).

Is it clear from the data why the learning cycle failed, and are there any recommendations that can be made in order to achieve a successful learning cycle?

Thank you,

Justin