I'm configuring an LM3409HV to be linear across voltage, and Analog Dim. I came up with values for the components that should produce results in line with what I need.

Please see attached spread sheet.LM3409HV_Experiment_330uH_60KRoff_0.22Rsns.xlsx

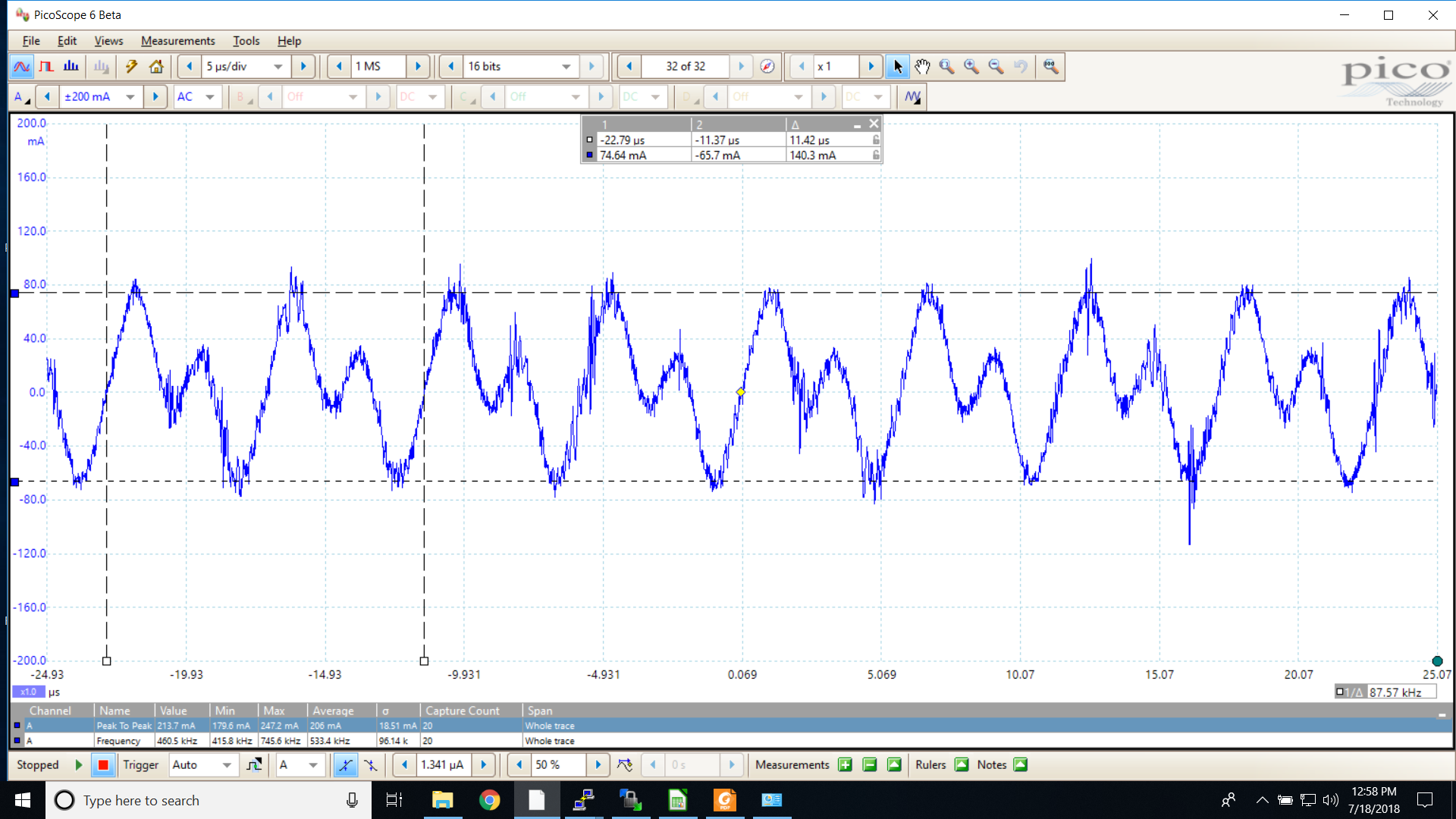

However, when I look at output ripple (example is 32V load 1.1 Amps approximately, IADJ is just above 1.24 volts), I'm seeing a ripple that is almost an order of magnitude bigger than what the math predicts.

You can see the component values I'm using in the excel spread sheet. The production version of this product uses different values and nicely matches the math.

Any ideas as to what I'm doing wrong?