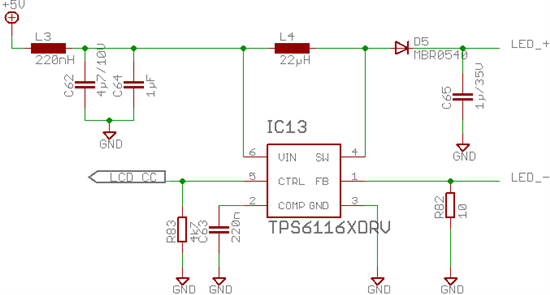

Dear sirs,

I have successfully implemented the TPS61161 to drive a string of 9 backlight-LEDs, using the configuration from the datasheet. But after having built 100 units, I have 5 ones on which the TPS61161 had to be replaced (and no component else). On two occasions the LED string FPC had been accidentally removed during operation, on the other times it had been removed before applying power. Since I have to revise the PCB and the IC should be Burn-Proof itself I would like to ask for hints why the IC fails when it should not. The IC is power from 5V, the signal LCD_CC is a PWM signal with an amplitude of 3.3V and a duty-cycle of 80% default. I can not find the dimming frequency striving through the linux-sourcecode but it has to be between 35kHz (most likely) and 4.3kHz (prescaled by 8).

When the device fails, the output is permanently on (Vin-0.15V).

Thank you for your ideas,

Guenter.