Other Parts Discussed in Thread: EV2400, BQSTUDIO

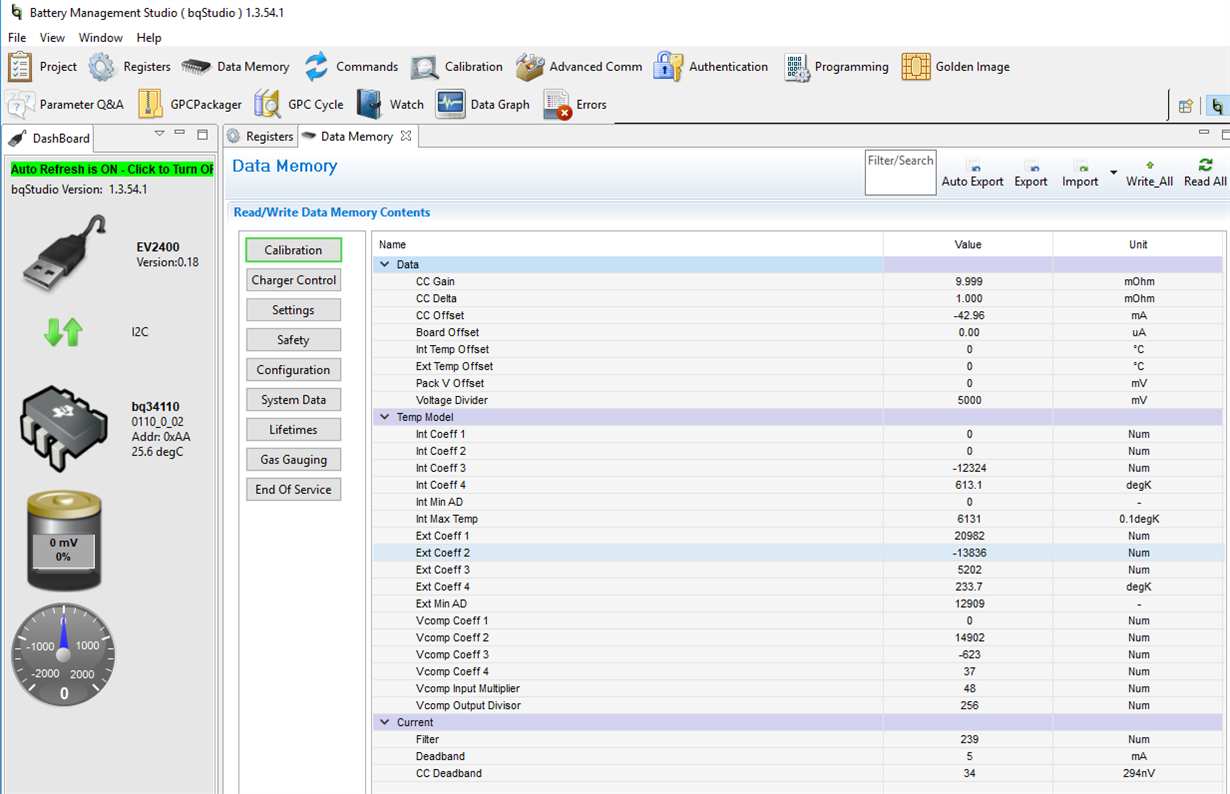

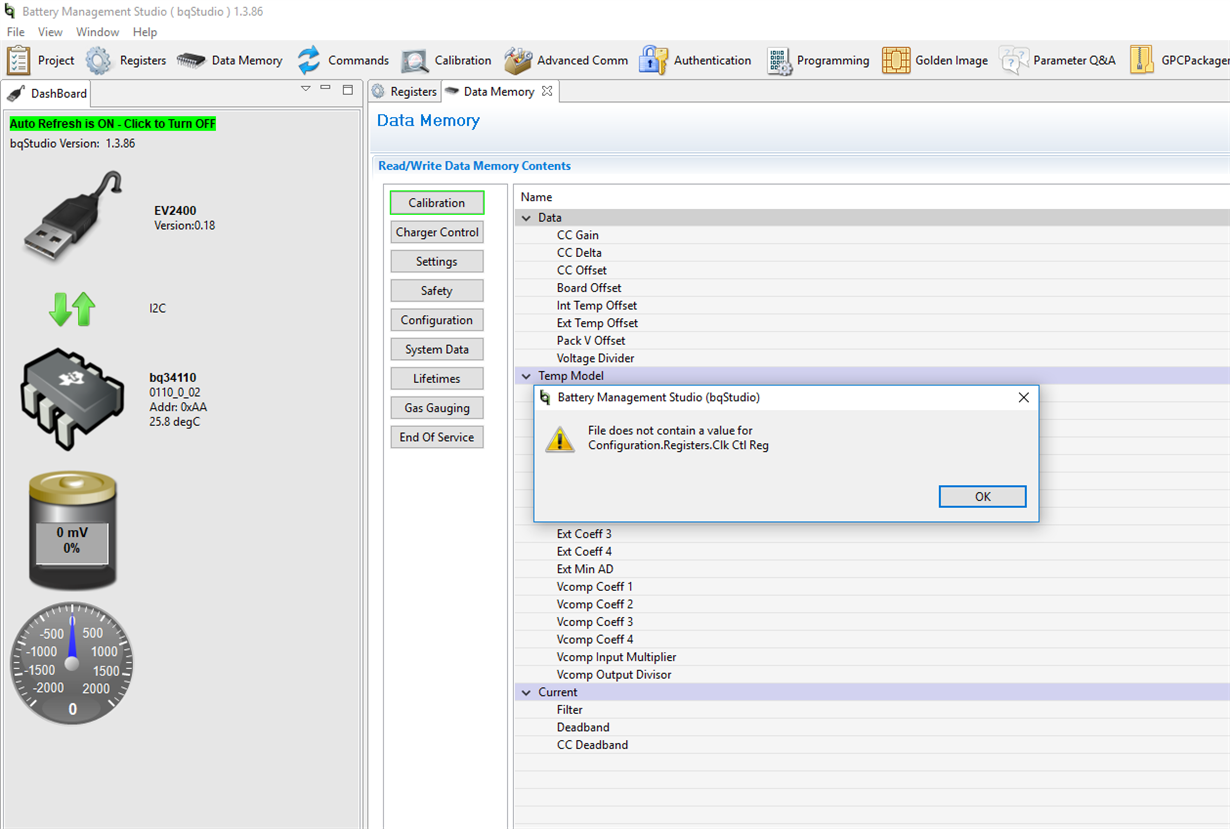

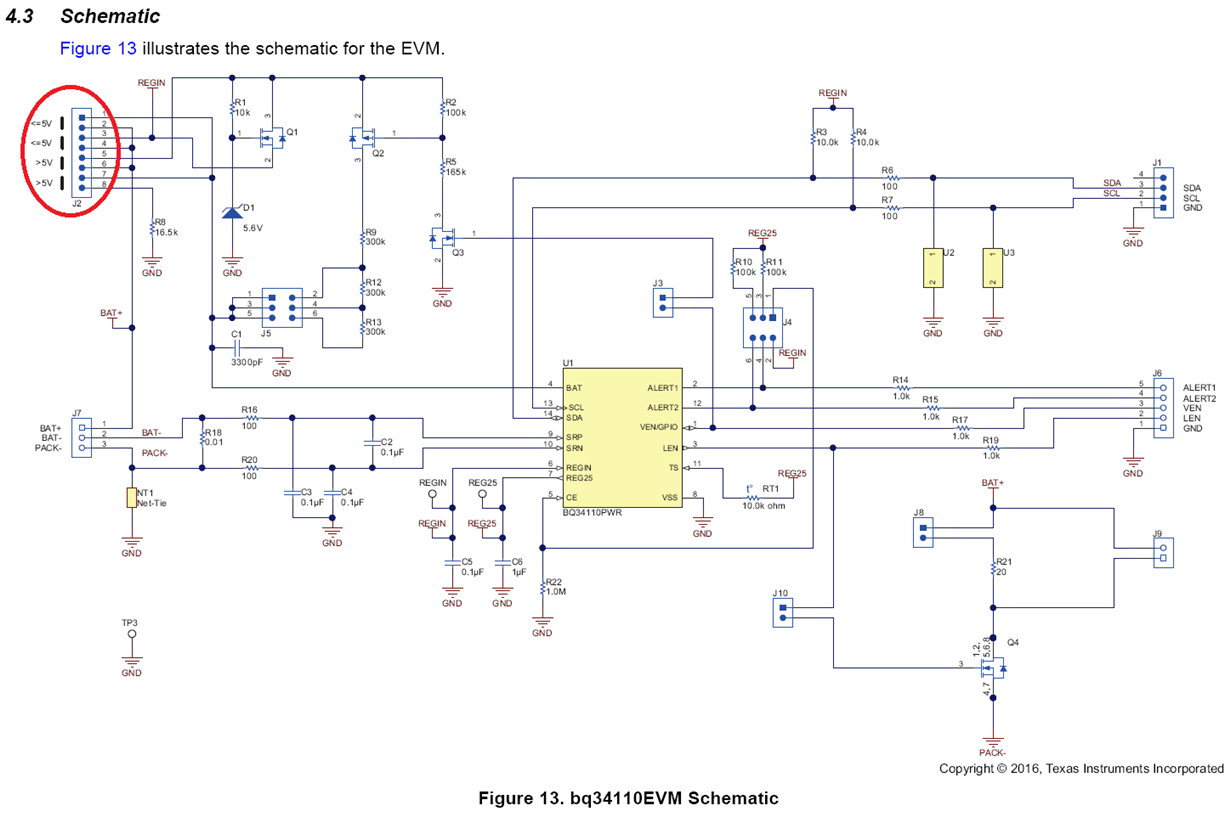

My application is to monitor the fuel gauge information of a 10-cell NiMH battery pack. I have read the bq34100 datasheet and technical reference manual and "using I2C comms with gas gauge". But I am still confused about the steps of how to configure this chip, as there are so many registers and calibrations. Which ones need to setup first to get it going? Right now, I can send a I2C message and get some bytes back. But please send me some basic steps needs to done for using this chip. Any application examples please? I am using a STM32 arm microcontroller. I used "HAL_I2C_Master_Transmit" and "HAL_I2C_Master_Receive" functions, not sure whether it is the best way. I have got both my circuit and bq34110 demo board for hardware. I ordered a EV2400, have not received it yet.

Thanks and best regards,