Hi

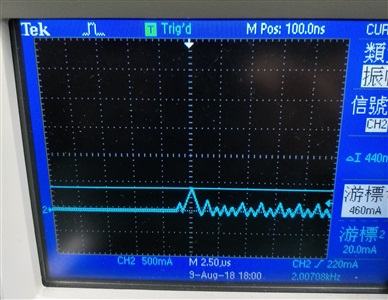

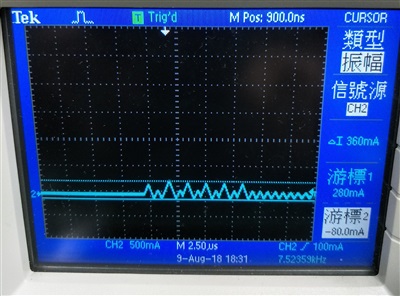

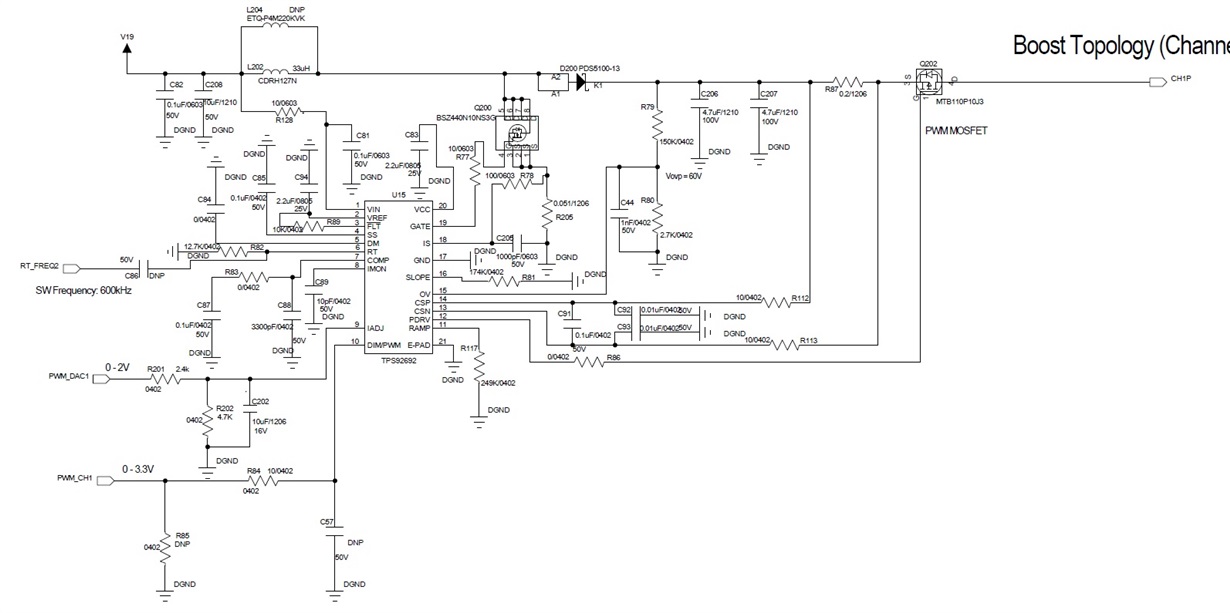

I use TPS92692 as booster to light up 15 LEDs. I have low dimming requirement and need LED current low to 0.1mA. Hence I set IADJ voltage to 10mV and use PWM dimming. PWM duty may change from 1/50 to 50/50. I found LED may flicker from PWM 1/50 to 7/50 and I measure the inductor current as figure1. I also design TPS92602 for this low dimming application but TPS92602 doesn't have flicker issue. The inductor current as figure2. The inductor current very different in low dimming and could TPS92692 low dimmig behavior like TPS92602?

Figure 1. TPS92692 inductor current

Figure 2. TPS92602 inductor current

Thanks

Best regards

Janson