Dear Friends,

We had used TPS65218 B1 in our custom board.

The issue I faced is PMIC shutdowns (All rails off) randomly.

Please guide me how can I debug and find the actual reason behind shutdown.

I had verified that current of each rails are well below limits.

Vin is +5V

Can you please send me the PCN of revision D0.

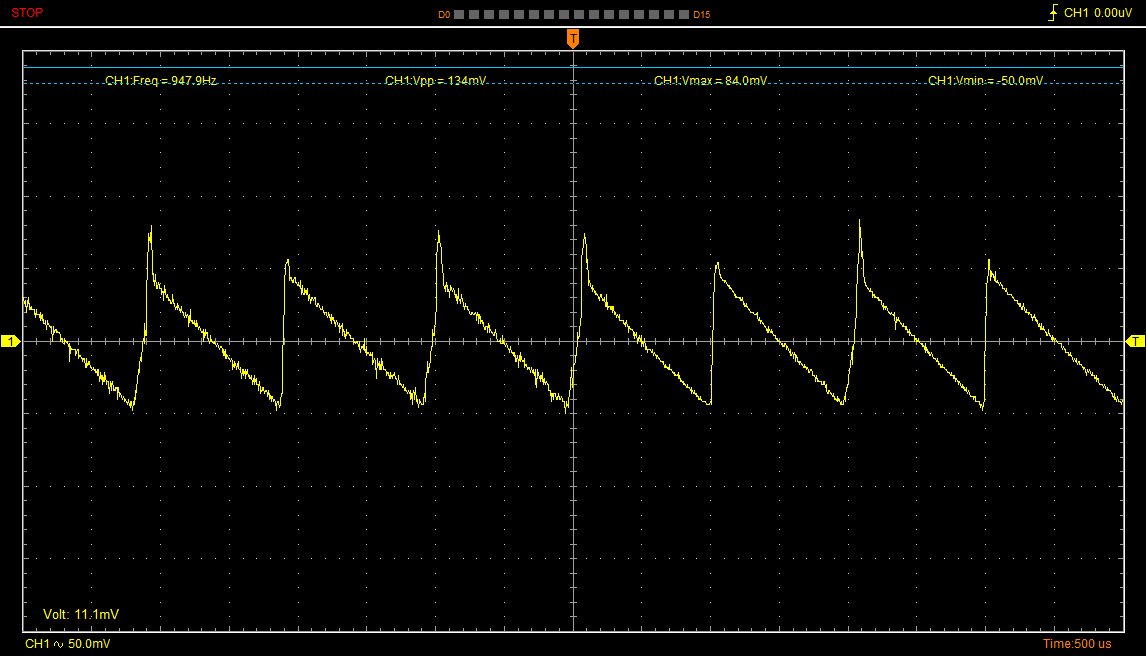

I had unmasked the all interupts using I2C. Now on INTA pin I'm getting the pulse when there is an event generated by PMIC like PB pressed or any fault arises.

Now I want to read the PMIC status register and print on console when any event interupt arises.So that I knows which event was generated before shutdown.

Any one had done this before or guide me how can I do this.

Thanks

Chetan