Other Parts Discussed in Thread: TPS62147

Hello,

I have a portable device which needs some battery upgrade (currently it uses two CR123 elements which are aweful). It has a simple ADC onboard to track the input voltage and show the percentage of batteries (it is critical to know the percentage otherwise I didn't bother).

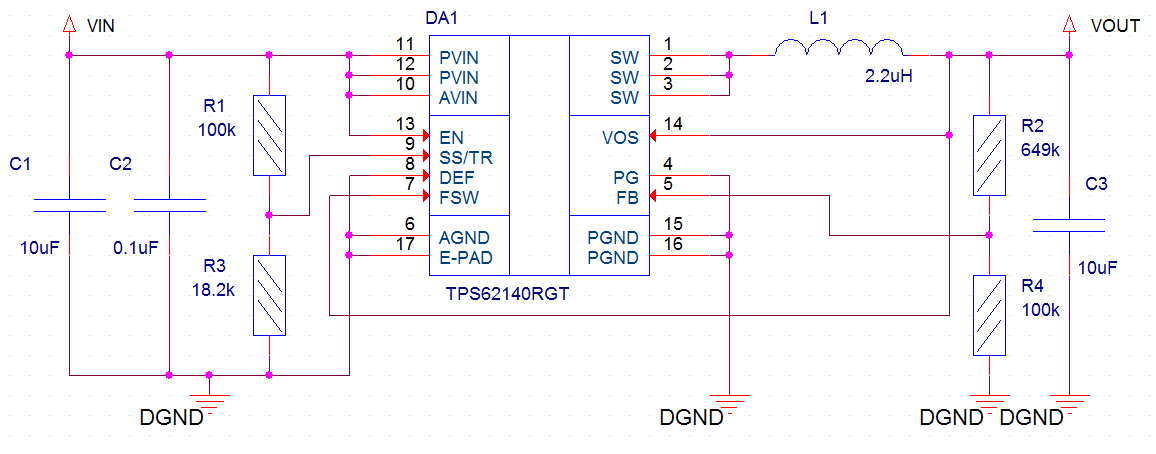

I'd like to use a tracking function of the TPS62140 to lower the maximum input voltage from my new battery pack (two 18650 in series) to the device's limit of 6V with the simple resistor devider connected from the battery pack to the SS\TR pin. At the datasheet it is said that "There is no theoretical limit for the longest startup time".

May I assume that such system would work for as long as the batteries dure and the output voltage of the TPS62140 would decline linearly depending of the voltage applied to the SS\TR pin without any issues?

Is it OK to build a continuously tracking dc-dc converter?