Dear All

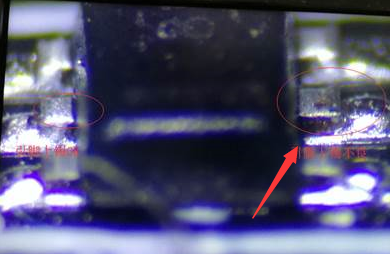

Look at the below picture, the both sides of pins have packaging materials. Is it normal ? Does the packaging process require removal of these packaging materials ? Because it will stop to sold the both sides of pin .

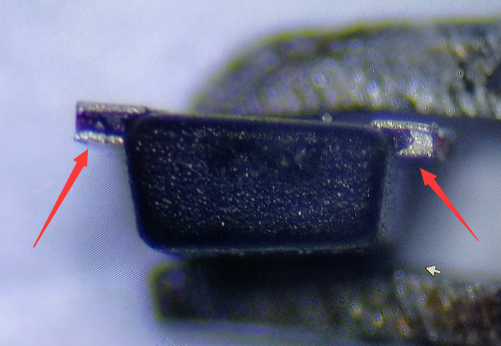

And the second below picture, the bottom of pins tin plated which are not smooth, the reflection brightness is inconsistentis, is it normal ? why?