Other Parts Discussed in Thread: PMP20183,

Hi

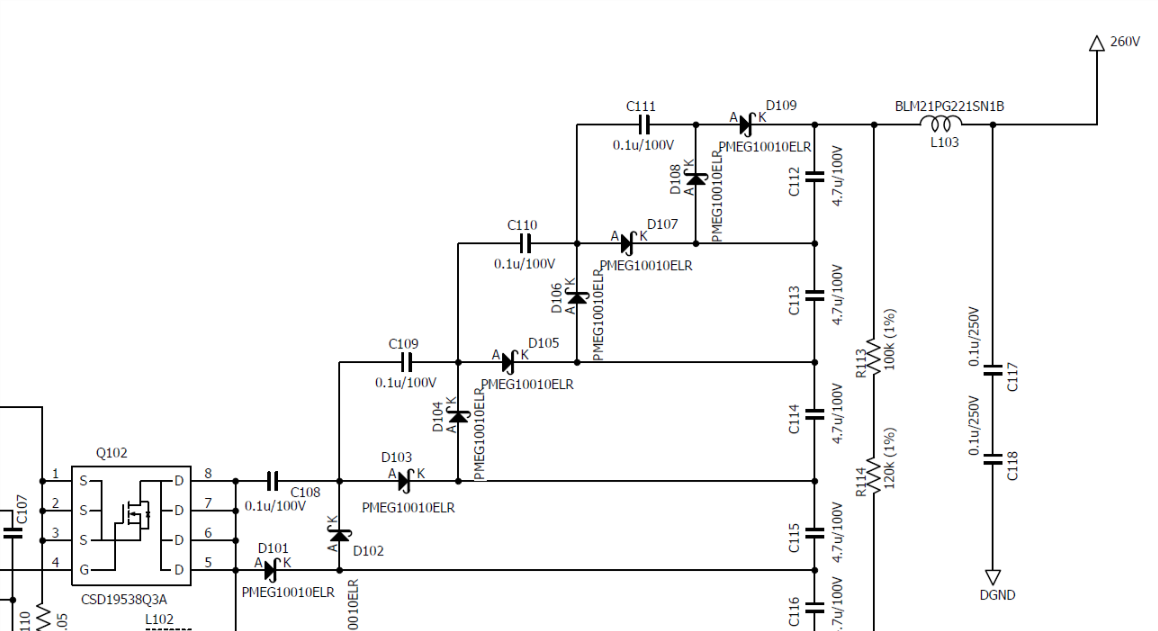

Our customer refers PMP20183 to design the circuit for following requirement.

V_INPUT : DC 9V

V_OUTPUT : 260V (Max)

I_OUTPUT : 10mA(Max)

According to the requirement, PMP20183 looks to be good reference design while a little change might be needed.

So, what should we modify PMP20183 to meet the requirement? Could you please tell us your view?

BestRegards