Other Parts Discussed in Thread: TIDA-00318,

Hi everyone,

I have designed a PCB with the BQ51003. I have more or less replied what is reported in TIDA-00318, changing only the resonant circuit capacitance values.

The circuit is made on a flexible PCB, and the rx coil is printed on it.

I have followed step-by-step what is reported on the datasheet, but I'm facing some issues in the charging process.

When placing the coil onto a QI-compliant charger, it doesn't resonate and I see on the AC1-AC2 pins a burst every (more or less) 500 ms with a 2Vpp amplitude.

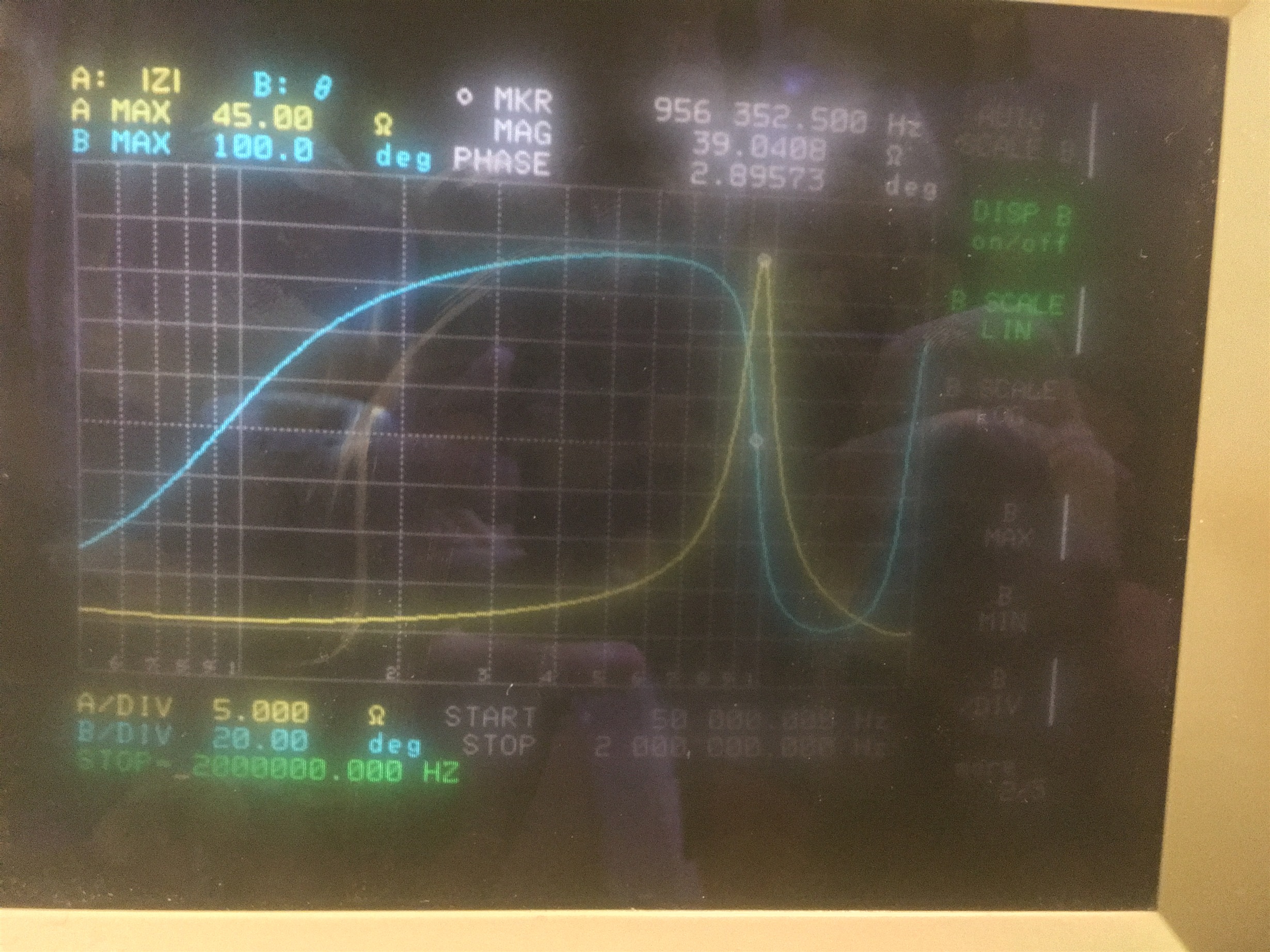

I'm attaching a picture of the impedance analyzer, when placing my coil onto the QI charger turned off, with the probe tips on AC1-AC2.

The free air peak is around 988 kHz.

My inductor is 670 nH and my capacitors Cs = 3.7 uF and Cd = 37.3 nF.

Can someone please help me?! I really don't know what to do more!

Thank you!!

Andrea