Other Parts Discussed in Thread: LP5912-Q1, LM26420

Hi,

We are using TI PMIC LM26420-Q1 and LDO LP5912-Q1 in our automotive design solution.

The schematics for the supply are as shown

The 2.2V output from the BUCK is fed to a switching load and also goes as input to the LDO. The 1.8V output from LDO goes to analog circuitry. The switching load and analog circuitry are on the same chip and we have decoupling capacitors of value 10uF, 2pF for 2.2V rail and 0.1uF for 1.8V rail near the chip.

We are observing spikes due to switching at 2.2V output and 1.8V output at room temperature. At 105C, the amplitude of spike is more and is causing performance degradations.

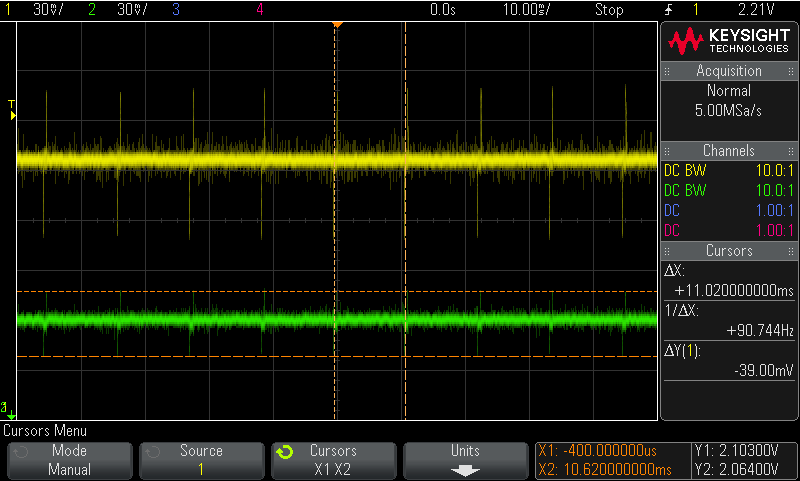

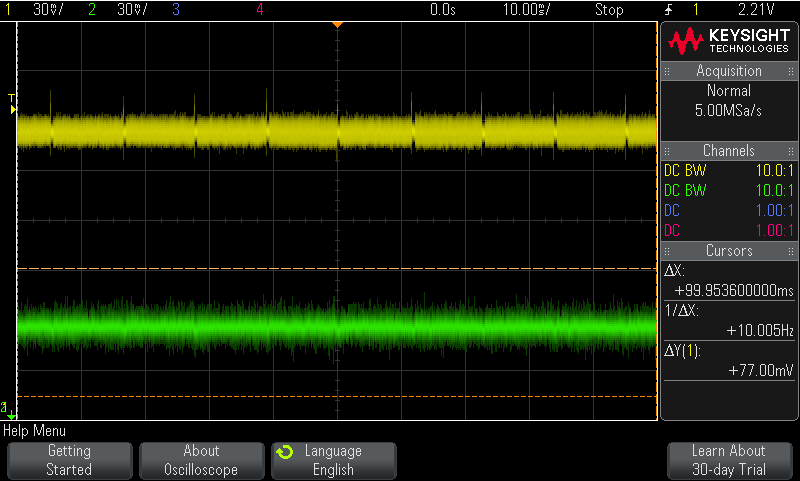

The output observed during transmission at 25C:

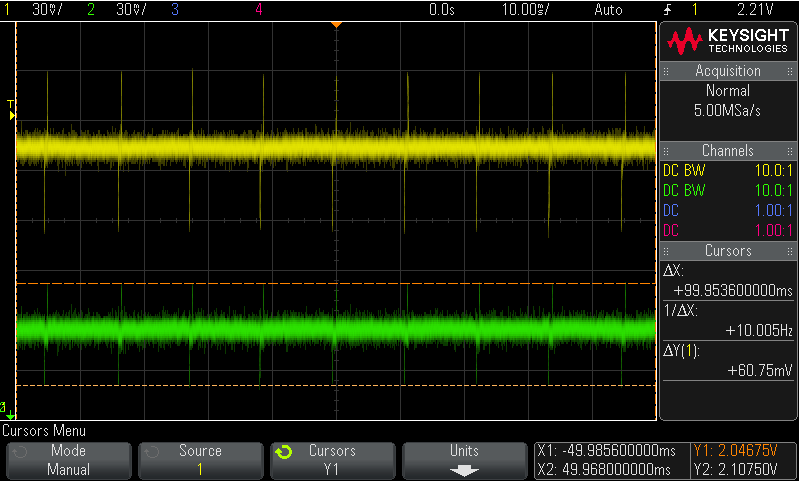

and at 105C:

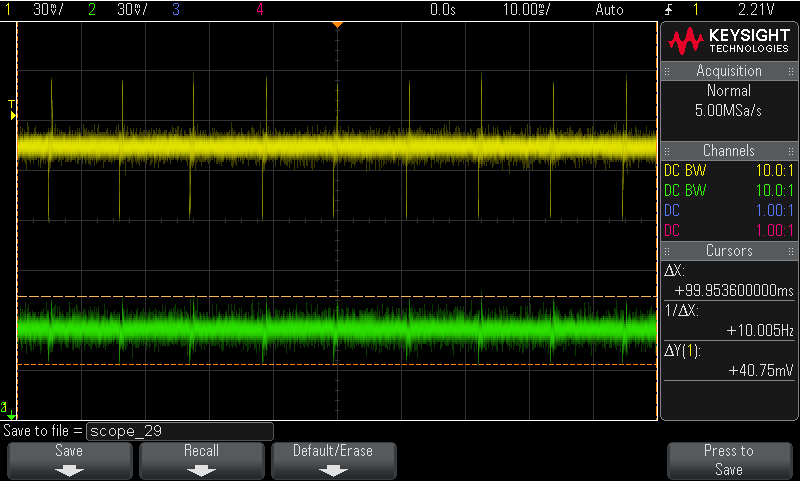

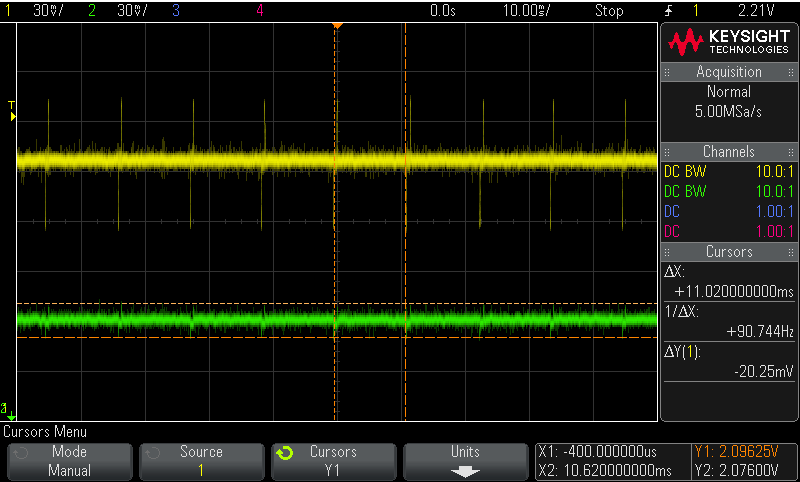

Yellow corresponds to 2.2V buck output, green to 1.8V LDO output.

The performance is improved at 105C by using a 47uF Capacitor at 1.8V LDO output:

Even at 25C, with 47uF capacitor, the spikes are reduced as:

Currently Cap value >47uF needs to be used at output of 1.8V to improve performance. The capacitor value seems too large and will increase BOM cost. Also this seems like a quick fix and we are not sure of the root cause of the issue.

Do you have any suggestions to root cause the issue and improve performance?

In our previous design we used a different make PMIC, on which such issues were not observed. In current design we replaced the PMIC with TI solution keeping everything else the same, that is, the load and the decoupling capacitors near the load.

Previous PMIC was a dual buck + LDO single chip solution.

Output from the previous PMIC is coming as:

What changes do you suggest to get a clean output from the TI PMIC and LDO?