Other Parts Discussed in Thread: EV2400, BQSTUDIO,

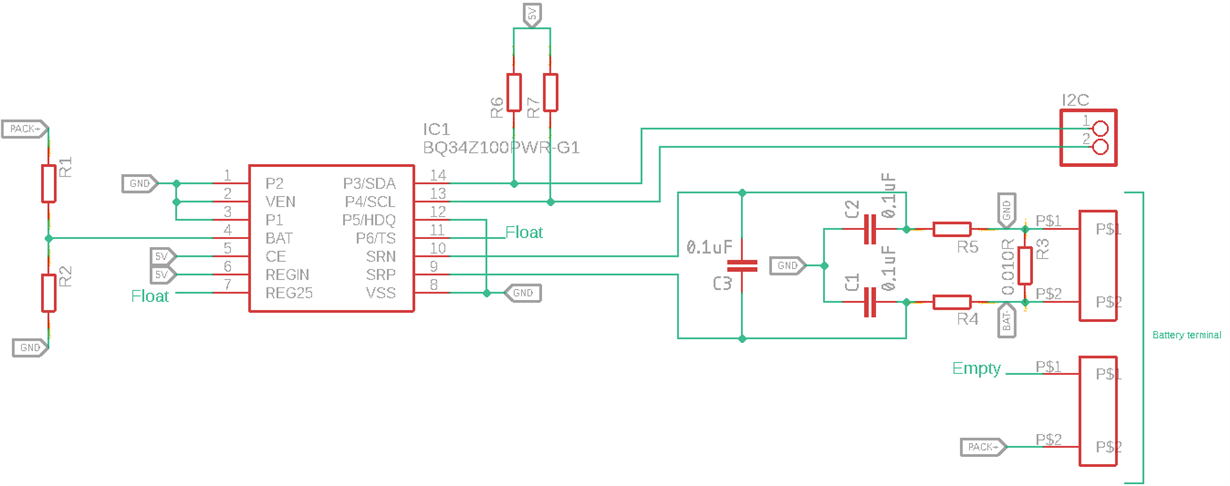

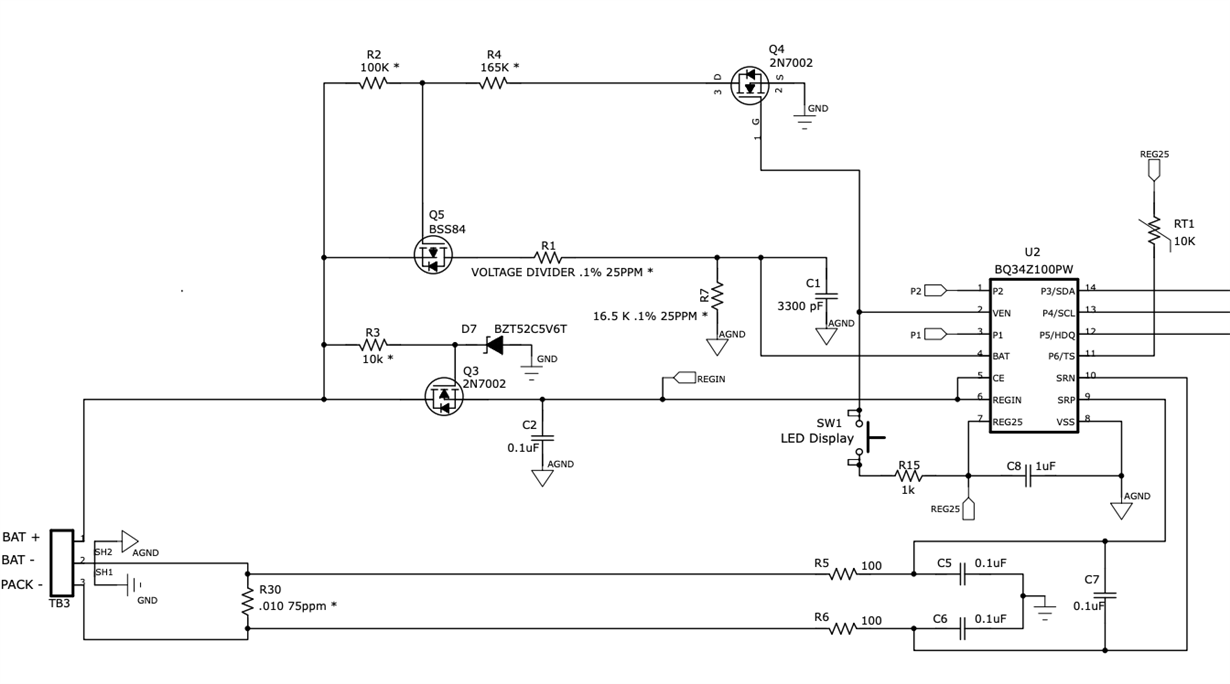

I don't have evaluation module of Fuel gauge and EV2400 for communicating gauge to BQ studio. I have made following circuit for operation. I am connecting Gauge via Arduino. Can you tell me exact calibration process for gauge through Arduino or any other microcontroller.