Other Parts Discussed in Thread: TPS92515

I’m puzzled about the behavior of the VLEDx pin.

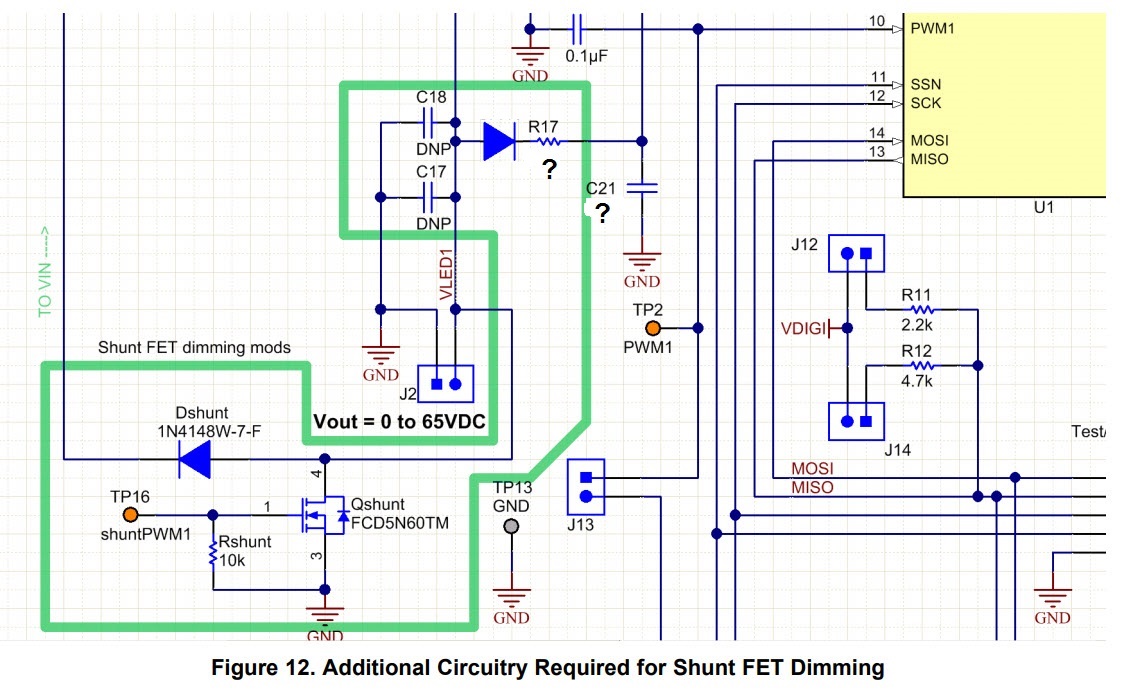

It is clear that in TPS92518 evaluation board with shunt dimming modifications, VLEDx will have a voltage closer to VLED * d, instead of VLED (where d is the shunt dimming duty cycle). It will have some ripple (low pass filter set at 159Hz), but since shunt dimming frequency will be >1kHz, it will be negligible.

I can see two issues with this:

- VLEDx ADC reading will not make sense, for two reasons:

- PWM pin is not switching, since I’m doing shunt dimming. So I won’t know if the ADC reading is made at off or on.

- Even if I read the ADC registers when I’m sure LEDs are on, the ADC reading will be VLED * d instead of VLED.

- The controller will not work in “constant μs*V” operation: even if the LED forward voltage will stay fixed, VLED pin will read a different voltage for each dimming duty cycle, thus the controller will set a different off-time for each duty cycle. This, as far as I understand, is unwanted. If I understand correctly this can be avoided by fixing VLEDx to a fixed voltage, “however current regulation degrades” as the datasheet says.

I think however that there is a solution for this. For a “similar” (but not quite the same) issue, TPS92515 datasheet (fig. 14) shows a diode between the driver output node and the pin that controls off-time. This diode, applied in our case in series with R17 in the evaluation board schematic, could make the circuit work as a “peak detector”, effectively making VLEDx pin voltage equal to LED forward voltage, approximately, independent of dimming. For this to work, C21 should be big enough to avoid being discharged too much by VLEDx pin input resistance.

What do you think of this issue? Has it been seen to compromise the performances?

What do you think of the proposed solution?