Other Parts Discussed in Thread: INA148

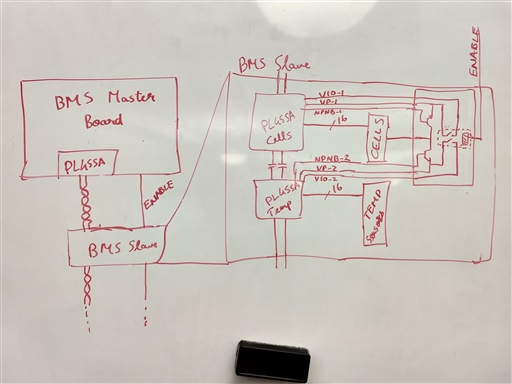

Since my application requires all 16 cell temperatures, I want to use the second device to measure cell temperature. The image below briefly explains how I plan to achieve this.

The temperature sensor is a temperature controlled voltage shunt(a zener diode with zener voltage proportional to the temperature) shown in the drawing as a simple diode due to lack of creativity. Cn is the voltage sense inputs to device1, the primary cell voltage measurement device. Tn is the inputs to device2 which is used to measure the temperature sensors' voltages. An is the actual voltage across the temperature sensor(the one with a diode for a symbol).

This configuration allows me to measure all temperature sensors with minimal additional cost, and fewer components on the board. The precision of the temperature measurements is up to 16x worse, but for my temperature sensors, that corresponds to <1C, which is sufficient for me.

However, this raises some issues, should I provide separate power supplies to each chip? I will be removing VIO to cause the chips to enter SHUTDOWN mode. And use a WAKEUP command over differential comms to turn them back on. VIO is supplied from VP, but a relay in series is used to connect/disconnect it, allowing externally hardware controlled shutdown of the devices as required by my application. Having one of the devices (for example, device1) controlling the NPN power supply, might unexpectedly remove VP and VDIG power to device2 if device1 enters SHUTDOWN sooner after VP power is lost. Is this acceptable?

This question is more of a clarification. If I use a single NPN power supply, the NPN controller (device1 using the case assumed above), would have to be the lower device in the communication stack right? This would allow it to receive the WAKEUP command first, and generate VP before device2 above it turns on. Will this work at all? Would the VP rise time be longer than the propagation delay through device1 to device2 and the subsequent powerup of device2 that isn't configured to control the NPN supply? Maybe this is answered in the datasheet, but I was unable to find it.

Are there any other issues that I might have missed when using these devices in this manner? Especially since this is far from the use case described in the datasheet.

Thanks in Advance

Regards

Chaitanya

Electrical Captain

Illini Formula Electric

illiniformulaelectric.com