Other Parts Discussed in Thread: LM5145, LM5185

I have made a DC/DC with LM5085, but the voltage will drop when the load is added.

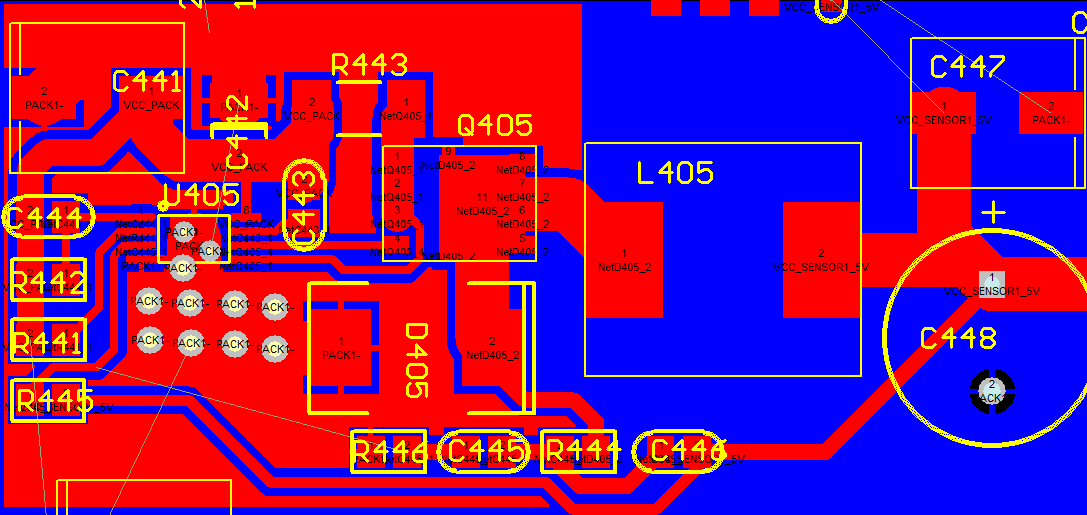

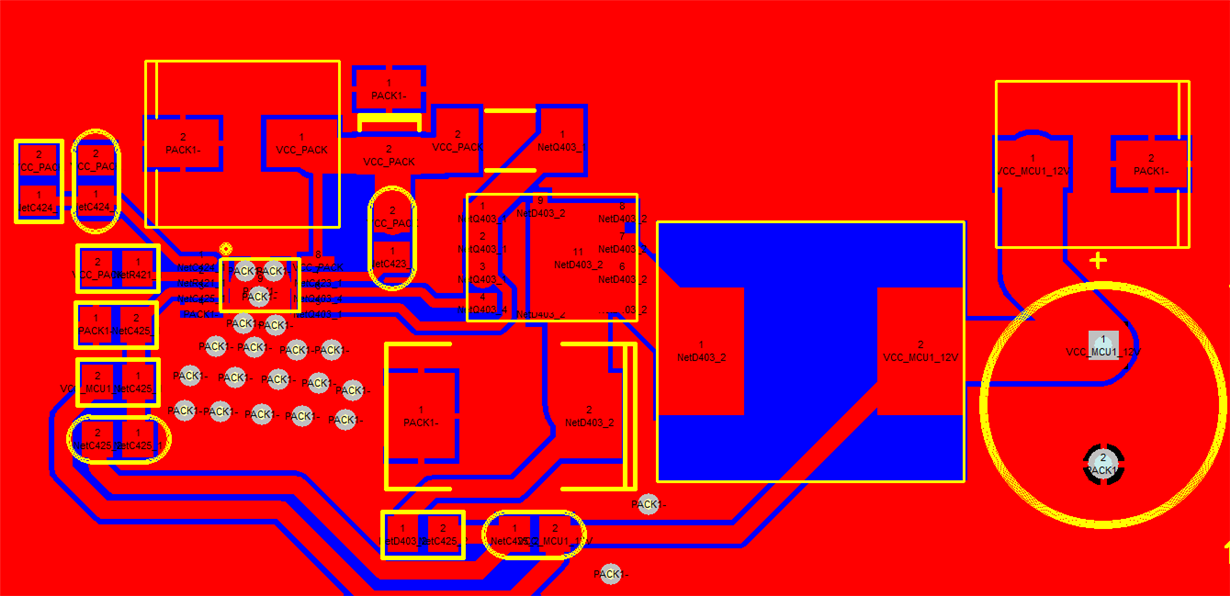

Therefore, I have changed the layout of LM5085.

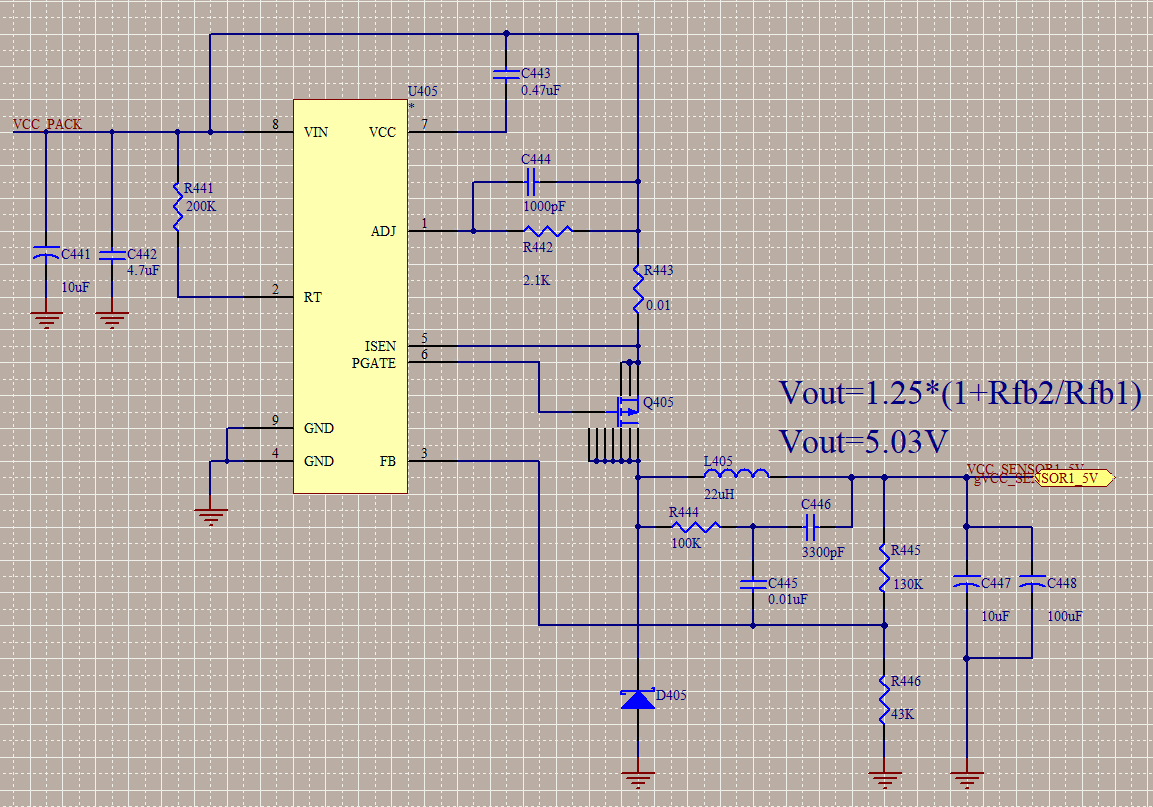

The schematic and PCB is listed as below.

Would you help me have a check?

Would it be OK for 7A load?